Technology brings convenience and efficiency in our lives, so it is should be made accessible to everyone at the most affordable cost possible. Let us take a look at the progress that has been made in developing the most affordable IoT sensors that there are.

The Internet of Things (IoT) is a network of physical objects called things, which include electronics hardware, software, sensors, power source, and network connectivity that connects these objects to collect and exchange data. The IoT devices need to be self-supporting for their longevity, which is essential for them, but they also need to be low-cost.

The world as a whole is not a very rich place. According to the data from the World Bank Atlas, almost half of the world, or over three billion people, live on less than 2.5 dollars a day, while 80% of humanity lives on less than 10 dollars a day. It is important to keep their requirements in mind while developing new tech as they cannot afford the iPhones and the iPads. We need to develop technologies that are suitable for them as well and can improve their quality of life.

There is also a need for low-cost IoT platforms due to the issues that are being faced in the following sectors:

Security. For homeland security as well as cyber security.

Healthcare. For web-enabled healthcare initiatives, diagnostics, rural healthcare, etc. Clean water and sanitation issues need to be addressed as well.

Agriculture. 80% of the water gets used for agriculture, so saving water is very crucial. We only have 4% of the world’s water resource in India for 18% of the world’s population.

Pedagogy. India needs to create a million jobs per month to meet the demand and address their training needs, educational requirements, and skill development.

Environment. Sensor networks are needed to regularly monitor and transmit information related to the population, water quality, etc.

Low-cost cardiac diagnostic system

Back in 2004-05, we formed a multidisciplinary group and started to think about what all could be improved and address the requirements at the same time. One of the first problems that we took on was a low-cost cardiac diagnostic system. Every third death in India is cardiac related. We strived to make the diagnosis simpler for everyone at the lowest cost possible.

There are multiple cardiac markers to open in CK MB myoglobin markers. We started working on some of these markers, because sometimes the cardiac muscles release some of these proteins into the blood when a patient starts to die. If troponin concentration is high, one needs to be admitted to a hospital immediately. With the help of some simple technologies these markers can be detected. But these markers need to be tested repetitively as it is not a one-time measurement need.

We wanted to build such a system, so we started working on iSens that could detect myocardial infarction. You just need to take the blood sample and filter it out. There are micro channels there along with the biosensor array for different cardiac markers and then there is a small tabletop system.

At the time of development, we realised that these are all disposable systems and silicon devices turned out to be pretty expensive to be disposed of frequently. While all the associated electronics are made of silicon but for the actual cartridge we started making use of polymer sensors. These are all piezo-resistive polymer cantilevers that can be implemented with low-cost techniques.

When an antibody gets coated on the cantilever and binds to the cardiac proteins, it causes a reaction and generates a stress, and that stress goes on to cause a strain. Any binding of the cardiac protein to the cantilever surface gives rise to an electrical signal, and that is how you know whether the cardiac markers are of a high or low category.

A new approach to explosive detection

Using the same technology, we started working on explosives, because in India security is a major concern. We wanted to develop a simple system that could be used to screen people at the airports and even in buses and trains. We stumbled upon a very interesting technology for which we have been granted patents in the United States and India.

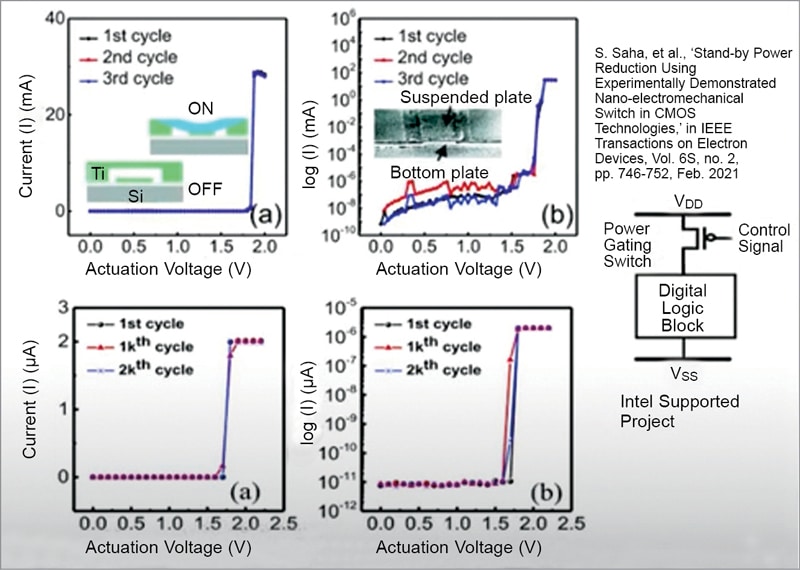

In this technology we make use of a nano mechanical switch between two plates. The distance between the two plates is approximately 20 nanometers. This distance becomes narrower when explosives bind on the surface of one of the plates. When this gap becomes 5 to 10 nanometres between the plates, a rush of current occurs. This creates a lot of thermal energy, which leads to a thermal shock and thus to an explosion. That nano explosion destroys the switch.

We started fabricating these switches in such a way that they could withstand multiple cycles (see figure above). The switches can now close and open up to 2000 times.

Even Intel was very keen on using this technology for standby platforms. So, we started a company called Nanosniffer using this technology. Last year it was released as a product. This technology is now commercially being used at airports. It is important to know that it takes about ten seconds only to do the detection.

mepr-show rules=”144188″ unauth=”both”]

|

Why we need to miniaturise the diagnostic systems

|

|

All the explosive detectors at airports and other places were earlier based on spectroscopy principles, which made them very expensive. But this technology is much simpler. You collect 20 nanograms of this material and explode it by giving it a thermal shock in a tiny nanomechanical switch. This thermal shock destroys the switch.

We are also working on miniaturising the micro sensor based explosive detector. We are trying to make it vapour based so that it could easily be put in cars, buses, airports, and other places. One of the ways to power these sensors could be by using the vibrations in the buses and trains. This could be done using piezoelectric methods to convert mechanical vibrations into electrical signals. We have started working on a platform of piezoelectric generators.

We are looking to use lead-free materials as piezoelectrics because lead based materials are harmful to the environment. Using applied materials, we are working on a project to develop lead-free piezoelectric materials and have filed patents for it. Now our goal is to integrate these piezoelectric harvesters into the IoT node explosive sensing. This can be discretely integrated into the existing buses without having to modify their body.

Sensors for agricultural applications

We have also started working on agricultural sensors. One of the reasons for us to get involved in this area was that the government of India has distributed a lot of soil health cards to farmers who are expected to use them to monitor the health of the soil. Farmers usually go to agricultural labs to get their soil checked. But there is no denying the fact that the whole system is faulty as there are barely any farmers who find it easy to maintain the soil health cards.

So, with the help of IIT Delhi and IIT Mumbai we have developed multiple prototypes for soil health monitoring. We are also making sensors for soil moisture measurement for which we started a company called Soilsens about three years ago. We have transferred some of the technology to them and now they are commercially selling this to farmers and the others.

We are also trying to build an integrated bio-dome using artificial intelligence and machine learning for diagnostic purposes. The goal is to integrate all the non-invasive technologies that are being developed by various startups into a single bio-dome.

India is a home for great opportunities, some of which are:

- MEMS/Micro-fabrication/Batch-processing approaches ideally suited for meeting the cost and power requirements

- Address the bottom of the pyramid as most MNC products target only about 100 million of India’s 1.3 billion population

- Business model required for meeting cost and maintenance requirements; calibration is a key challenge

- Local R&D for product development essential for reducing the costs and for taking care of the needs of the people in India, be it for agriculture, or security, or healthcare applications

- Multiple initiatives taken for startups by the government of India to develop technologies such as IMPRINT, UAY, GITA, BIRAC, and TSDP

The IoT technologies need to be designed in India keeping in mind the following:

The economic conditions. The techniques should be affordable for the farmers as they are not often financially sound.

Social, cultural, and educational backgrounds. Farmers are not very educated and they cannot use smartphones efficiently, unless the content is written in their local language.

Infrastructure challenges. There is a need for good infrastructure in order to calibrate these sensors in remote areas on a regular basis.

Power requirements. The farmers may not be able to change the batteries regularly, hence there is a need for a continuous power supply.

This project was founded by Intel while Nanosniffer has commercialised it. Soilsens is also selling some of these technologies today, which are multi-study projects that contribute to their efficiency.

This article has been put together from a tech talk at VLSI 2022 by Prof. Ramgopal Rao of IIT Delhi. It was transcribed and curated by Laveesh Kocher, a tech enthusiast at EFY with a knack for open source exploration and research.

[/mepr-show]