Electronic gadgets are practically becoming slim. Even the clothes you wear can become your intimate companions, enhancing your functional ability. There are ‘e-clothes’ for almost every requirement that can make life easier, funnier, smarter and even healthier.

e-textiles, also called ‘e-fabrics,’ have various electronic components and interconnections woven into them. These fabrics can then be mounted on readymade garments like shirts and jackets to perform specific functions. One important key to success of any electronic product is its adaptability with existing products. That is what e-textiles aim at.

These fabrics are highly flexible. The electronic components woven into them have smaller and thinner sizes that cannot be achieved with existing electronic manufacturing techniques. Also, the components and interconnections are less visible. They do not trouble the wearer and are less affected by environmental factors like moisture. The metallic fibres and textile fibres together form conductive fibres.

e-clothes can be worn in everyday situations where currently available computer applications would trouble the user. e-textiles can more easily adapt to changes in the computational and sensing requirements of an application. These also provide better power management and context awareness. In fact, in the future you may find e-fibres on walls, carpets and wall hangings of homes to increase their capabilities.

Design methodology

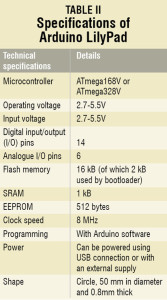

Typical challenges before e-textile designers are how to make connections between woven wires and how to mount electronic components in these fabrics. For several e-textile projects, the LilyPad motherboard is used. It offers a wide range of built-in functions.

Some of the key requirements for e-fabrics are that these should be able to withstand the applied stresses and be easily washable. They should be low in cost, easy to manufacture and unfading. Also, e-textiles should be fault-tolerant and self-configurable.

One must know how many processors and sensors are required for a particular application and how to put them between the fibres. Most of the microchips today are packaged with hundreds of pins. But for e-textiles microchips require only four to five pins. Further, space between these pins should be wider. Usually, an expression diagram is used in the circuit design of e-clothes.

One of the key requirements of e-textile components is interactive properties. That is, they should be able to change structure, colour and temperature in different ways in response to environmental stimuli.

Use of sensors in the circuit depends upon the application for which e-clothes are meant. For example, in automotive and road traffic applications, several factors play an important role. These include acceleration, temperature, humidity and light. Sensors capable of sensing such parameters should be selected.

In case of data transfer requirement, components having Bluetooth communication interface should be used. For wireless data communication, components having wireless data transfer capability should be used.

Focus areas

e-textiles are a must in situations where wearable computing is required. For instance, e-clothes are a perfect fit for soldiers. These are designed to handle bad weather and tough terrains, and can be worn comfortably because of their light weight. They can help maintain proper body temperature in freezing cold. Allowing flexible computing, e-clothes help soldiers detect and locate enemy vehicle movements. e-fabrics can be potentially fabricated to tents, parachutes or camouflage nets.

e-garments are already a big part of the US army. These are the main element of their next-generation soldier system.

e-textile fibres woven as mattresses in NASA space shuttles or space stations can make the life of space travellers better. Travellers will be able to breathe with less difficulty. e-fibres on their space suits can even pump out body heat and increase the rate of flow of fresh air.

e-clothes are a boon in healthcare as well. These are highly useful in rehabilitation also. An e-cloth worn by a patient can send his vital information like blood pressure and body temperature to a remote device like PDA, allowing doctors to monitor the patient in real time.

e-garments can serve to enrich the life of disabled people. Take the example of LuMax sonar ultrasonic range finder. It works on ultrasonic waves and LilyPad Vibe board. It alerts the blind to stop when there is a solid object in their way by giving a beep sound. Sonar technology along with adaptive technology can lead to a lot of e-textile miracles. A sonic realm jacket designed by Threads group at the University of Michigan is a great help to the hearing impaired. It consists of a series of vibrating motors kept along spine. These motors translate sound into tactile information.

In homes, e-clothes can act as your personal assistant. Their main purpose is to improve your quality of life. Take the example of a wallet with e-fabric over it. This wallet RFID-linked to a purse can make the purse beep if you are leaving home without the wallet. A piece of e-cloth on the door can provide an alerting beep sound if you forget to lock the door while leaving home.

In stage shows, light control, music and apparels of the artists are key factors. e-textiles easily ensure light control, illusion and communication required for stage shows. The first e-textile-based stage show was held in 1990 by a group of students from MIT Massachusetts. They developed artistic applications for electronics, such as a micro music playing system and apparels that change colour when their sensors are alerted.

There are many new ideas coming in, especially in the area of mobile phones. A team of scientists from South Carolina, headed by Xiaodong Li, is busy developing a t-shirt that can recharge mobile phones. This t-shirt consists of an interwoven piece of e-cloth with its yarns acting as electrodes. With these electrodes, the researchers were able to turn the fabric into several capacitors capable of storing electric charge. The circuit of the e-cloth even consists of microsensors that can absorb body heat and heat of the room.

Material aspects

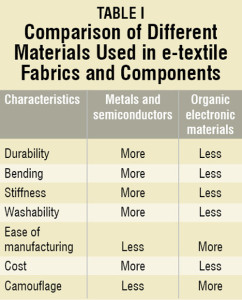

There are innumerable materials, from conductors to insulators, and from magnetic to non-magnetic. Materials that meet most of the demands of e-textile components should be selected.

Piezoelectric materials are of great use in e-textiles. A flexible memory fabric can be made of platinum and woven copper and copper oxide wires that form the memory circuit.

One of the focus areas of e-textile research is better material for e-yarns. Presently, an e-textile group is investigating a special polymer fibre for different uses. These polymers can act as batteries or as chemical sensors. They can even change their colour for disguise, helping soldiers to deceive enemy troops or create illusion.

Way to go

There is vast scope for research in various segments of e-textiles, including computing architecture and communication networks in fabrics.

Not just the hardware is enough. You need better software to operate them. So the researchers are working to develop software services necessary for almost all e-textile applications. Modelling and simulation tools are also underway.

Use of embedded system and distributed computing is expected to significantly improve e-textile applications. Embedding electronic components like sensors and microcontrollers in fabrics is sometimes called fibre electronics.

For many technological revolutions to be successful, implementation of present trends is largely required. That is where e-textile is heading for. Optimising energy usage, solar technology, hybrid energy systems, touchbuttons and screens are some of the hottest areas of research in e-textile segment also.