As technology advances, the synergy between advanced materials and emerging technologies ensures a reliable and efficient electronic backbone for our modern world

The rapid advancement in electronics has led to an ever-increasing demand for the protection of electronic devices from various environmental factors. Advanced materials such as epoxies, polyurethanes (PU), and polysiloxanes have emerged as frontrunners in this domain, offering excellent encapsulation, bonding, and thermal dissipation properties.

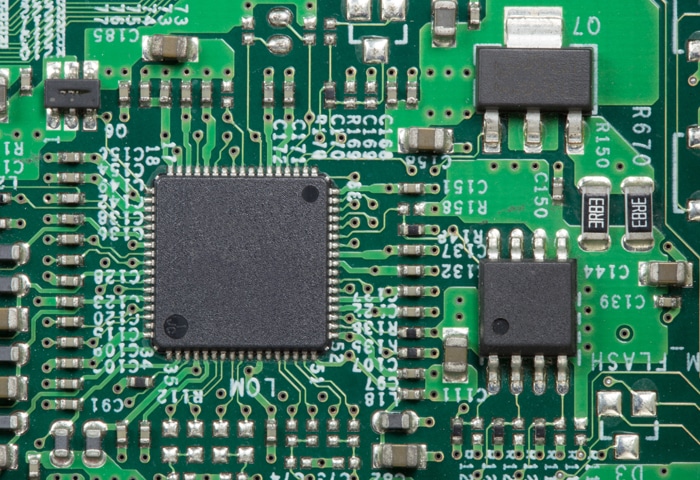

The continuous evolution of electronic devices, ranging from smartphones to complex industrial machinery, necessitates robust protection against moisture, heat, and physical damage. Advanced materials, including epoxies, PU, and polysiloxanes, have exceptional properties ensuring the longevity and reliability of electronic components.

Artificial intelligence (AI) and machine learning (ML) play a significant role in the proliferation of electronic devices and their consequential effect on the consumption of these advanced materials.

| Top companies producing advanced materials |

| 1. 3M 2. Amatech Innovation (Advanced Materials Technology Company) 3. Dow Chemical Company 4. Electrolube 5. H.B. Fuller 6. Henkel Corporation 7. Huntsman Corporation 8. Master Bond 9. Momentive Performance Materials 10. Panacol-Elosol GmbH 11. Shin-Etsu Chemical Co., Ltd |

Uses of advanced materials

We have classified advanced materials based on three major uses, viz, encapsulants, bonding materials, and thermal dissipaters.

Encapsulants

Epoxies and PU-based encapsulants provide a protective layer, shielding electronic circuits from moisture, dust, and chemicals, ensuring operational integrity even in harsh environments. Encapsulants are crucial in applications where electronic devices are exposed to moisture or chemicals, or in situations where the components need to be isolated from the external environment.

Bonding materials

Epoxies, PU, and polysiloxanes offer superior bonding capabilities, enhancing the structural integrity of electronic assemblies. Bonding materials are essential for the assembly of electronic circuits, ensuring that the components remain securely attached to the substrate or to each other.

Thermal dissipation materials

Efficient heat dissipation is vital for electronic devices. Epoxies, PU, and polysiloxanes infused with thermally conductive fillers facilitate heat transfer, preventing overheating and ensuring optimal performance. Thermal dissipation materials help in conducting heat away from sensitive electronic parts, preventing overheating and ensuring reliable performance.

Further details on the functional applications or advantages of these three types of materials are explained below.

Uses of encapsulants

Preventing corrosion

Encapsulants shield electronic components from moisture, preventing corrosion that could impair their functionality.

Enhancing mechanical strength

Encapsulants provide structural integrity, protecting fragile components from mechanical stress and vibrations.

Isolating components

In high-voltage applications, encapsulants prevent electrical arcing by insulating individual components.

Chemical resistance

Encapsulants with chemical resistance properties safeguard electronics in environments where exposure to specific chemicals is a concern.

Uses of bonding materials

Component attachment

Bonding materials are used to attach semiconductor chips, resistors, capacitors, and other electronic components to circuit boards.

Die bonding

In semiconductor manufacturing, die bonding involves attaching tiny semiconductor chips (or dies) to substrates, a process crucial for integrated circuit production.

Wire bonding

Bonding materials are used to attach bonding wires, connecting the semiconductor die to the package leads, forming electrical connections.

Encapsulation of wire bonds

After wire bonding, encapsulating the wires ensures their protection against mechanical stress and environmental factors.

Uses of thermal dissipation materials

Heat sink attachment

Thermal dissipation materials are used to attach heat sinks to electronic components like processors and power transistors, improving heat transfer to the surrounding environment.

Thermal interface materials (TIMs)

TIMs are placed between the heat-generating component and the heat sink. They fill microscopic gaps, ensuring efficient heat transfer and reducing thermal resistance.

LED applications

In LED technology, thermal dissipation materials are crucial to dissipate heat generated by high-power LEDs, ensuring their longevity and stable performance.

AI, ML, and consumption of advanced materials

The advent of AI and ML technologies has revolutionised various sectors, leading to a surge in the production of electronic devices. AI-powered applications, from smart appliances to autonomous vehicles, have significantly augmented the demand for robust electronic components. Advanced materials play a pivotal role in ensuring the durability and reliability of AI-enabled devices.

Encapsulants, bonding materials, and thermal dissipation compounds protect sensitive AI circuitry, enabling seamless operation even in adverse situations.

Moreover, the miniaturisation trend in AI and ML devices demands materials with superior thermal conductivity to dissipate heat effectively. Epoxies, PU, and polysiloxanes filled with thermally conductive additives address this need, enhancing the heat management capabilities of electronic assemblies in compact AI and ML applications.

In the fast-paced world of electronics, the utilisation of advanced materials such as epoxies, PU, and polysiloxanes is indispensable for ensuring the protection and longevity of electronic devices. The top companies in the field continue to innovate, providing cutting-edge solutions for diverse applications. The rise of AI and ML technologies further amplifies the importance of these advanced materials. As AI and ML continue to permeate various aspects of our lives, the demand for electronic devices incorporating these technologies will persist.

Consequently, the consumption of advanced materials will continue to grow, fostering innovation and shaping the future of electronics. In essence, the synergy between advanced materials and emerging technologies like AI and ML underscores the crucial role these materials play in safeguarding the electronic backbone of our modern world. As research and development in these domains progress, the evolution of materials and technology will go hand in hand, driving each other towards unprecedented heights of efficiency and reliability.

The author, Dr Mukesh Kumar Madhup, is associated with Amatech Innovation (OPC) Pvt Ltd, Ahmedabad