In a competitive market where fast designing is needed, how far will liquid crystal displays (LCDs) be an option for design engineers? Let’s find out.

Ten years ago, my senior told me that the LCD is going to die, but it has paved its way into our everyday life, starting from our phones to our vehicles. Segment LCDs were simple in design where an input channel was given directly to display digits. Even if videos could not be displayed, these LCDs were used on old auto meters and were pre-designed. Though a little complicated in design, thin film transistor liquid crystal displays (TFT LCDs) are becoming quite popular in smartphones and vehicles nowadays.

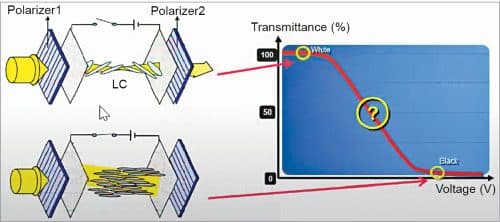

Liquid crystal can guide the light. For a TN LCD when the transistor of the TFT circuit is turned off and the LC changes the orientation of light rotation. After light passes through both the polarizers, we see the LCD completely white. However, when the circuit is turned on, the polarizer blocks the light, resulting in a black image. Hence liquid crystal is the core of the design that can direct the light as per its rotation.

Modes

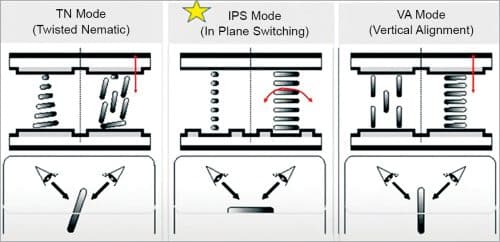

Based on the liquid crystal rotation, there are three modes, namely, In Plane Switching (IPS), Vertical Alignment (VA), and Twisted Nematic (TN) mode. In the IPS mode, the crystal switches horizontally and in the VA mode it switches vertically. Both have a wider viewing angle and a larger colour coverage but are high in terms of cost. The best performance can be obtained in the IPS mode. The TN mode has a narrow viewing angle with a small colour coverage, but it has the largest market as it is very cheap.

Fig. 3 shows the comparison for the same photo on two different displays when the liquid crystal is rotated in the IPS and TN modes. The performance varies as the angle changes. We notice that IPS has a better performance.

Thin-film transistor LCDs

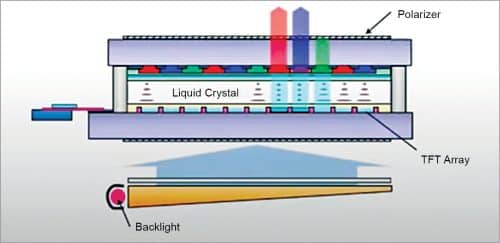

It is a display panel that uses liquid crystal to control the amount of light that comes from the backlight. The TFT acts like a switch that controls the liquid crystal. Each segment of liquid crystal is like a shutter that either blocks or allows light to pass through. Fig. 4 shows a TFT LCD where the top is an open cell and the bottom is the backlight.

The open cell has a nickel crystal sandwiched between the colour filter glass and the TFT array glass on which the transistor is built. The backlight structure contains a lot of optical sheets like diffuser, prisms, light guide, and reflectors. Backlight is of two types, namely, direct light that refers to the LEDs which are directly laid below the LCD. This method is used for big-size LCDs like TV or signage. For small- and medium-size LCDs, like phones or laptops, the side light is used where the LEDs are to the side of the LCDs.

Memory LCD for IoT displays

Memory LCD is the integration of one-bit memory into each LCD pixel. This makes sure that data transmission from outside the module is not needed when the displayed image does not change. The advantages that they offer are:

Low energy and power consumption. Two main reasons exist for the same. First the reflective displays do not need a backlight. Second, the memory needed integrated with the pixel does not need to be refreshed when showing a statistical image. For instance, in a 6.9cm (2.7-inch) screen, the power consumed is only 50µW when there is no image updating, whereas when an image data updates the power consumed is 175µW. The important thing to note here is that, unlike conventional LCDs where power is consumed at milliwatt (mW) level, TFT LCDs consume power at a microwatt (µW) level, confirming the long life of the battery.

Stylish display quality. The high resolution and crisp graphic image help for both indoor and outdoor readability. The high reflectivity makes it feel as though a paper is being read.

Engineer-friendly. The design interface is very simple with a 3-wire serial signal input (clock, data, and chip select), along with a ground and power supply.

Since the location of the sensors in IoT must be remote and needs a longer battery life, memory LCDs are widely recommended. Fig. 5 shows applications where memory LCDs can be majorly used, which are available from 2.5cm (1 inch) to 11.2cm (4.4 inch), in both black-and-white and colour. They can also be used in smart watches.

IGZO LCD for smartphones

The materials used to build the TFT LCD are indium, gallium, zinc, and oxygen (IGZO).

First, compared to the a-Sil (conventional silicon series materials), the electron can easily pass through the IGZO circuit. The electron mobility is 20 to 50 times faster than the a-Sil, resulting in the physical size of IGZO TFT being 1/7th of the a-Si TFT. This helps in achieving very high resolution.

Second is low power consumption. As we know the LCD runs at 60Hz in one frame. When the IGZO is turned on we only need a part of the frame and not the whole, resulting in a lot of power being saved.

Third, we achieve a LCD bezel. For instance, in a-Si TFT, the gate driver (COG) is at one side of the LCD, which cannot minimise the LCD side border. But for IGZO, monolithic gate drivers are used to build on both sides of the LCD, thus achieving a narrow frame.

Then there is the touch display. The touch and LCD signals are bound to interfere with each other, causing a problem. This is avoided in IGZO panels, as the touch detection can be activated when the IGZO TFT is in a rest mode. When the LCD is off, the touch is turned on and vice versa.

Reflective LCDs are eco friendly

The beauty of reflective LCD panels is their suitability for outdoor displays. Transmissive displays use a light source as the backlight, which, unfortunately, because of the ambient light, dulls the display. However, in reflective displays, the ambient light is utilised instead of a backlight. The features in a reflective IGZO are:

- High visibility and full colour display

- Low power consumption since there is zero backlight power

- Video support since it runs at 60Hz

- Easy on the eyes; usage of natural light can avoid strain to the eyes

- Implementation of backlight is optional; usage is promoted in a dark room

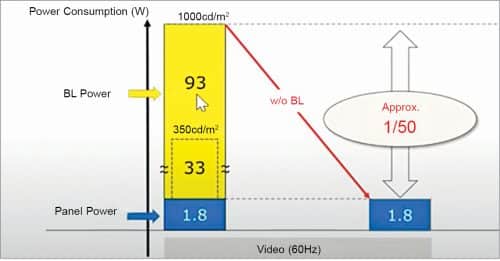

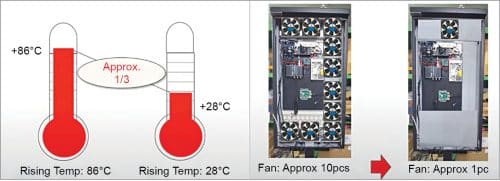

With no backlight being needed, we notice from the figures that around 95% of the power consumed is reduced. Similarly, the amount of heat generated is also reduced, leading to the fact that the number of fans needed to cool down the LCD drastically decreases. This makes the reflective LCDs much more reliable.

The remarkable fact is that, even an 80cm (31.5-inch) LCD can be run on a mobile battery (2500mAh) with a video being played for 24 hours without charging. Solar panels provide the freedom to move the system to different places. The solar panels along with the mobile batteries can help in signages located at bus stops, avoiding a lot of trouble. Not only bus stops, but this can also be implemented at petrol stations, vending machines, etc. There are various panel sizes available as samples and for mass production.

Regarding interfaces, there exist RGB and LVDS interfaces in the market, for many years. The RGB interface (for low-resolution panels) is mainly used for cars and motorcycles. The LVDS interface (for high resolution) is commonly used for industrial usage. Smartphones are using MIPI interface (low power consumption). EDP (power saving) is widely being used for laptop and monitor panels.

With such advantages that LCDs offer, design engineers have a tough job in choosing the right one. David suggests that it is best to match a design with different systems and interfaces before making the final selection. LCDs surely have the potential of being chosen as the best option for any application.

The article is based on a tech talk by David Yang, Deputy General Manager, SHARP, Singapore at TechWorldCongress.com. Transcribed by Sharon Abhignya Katta.

DAVID YANG is Deputy General Manager, SHARP, Singapore