The electronics industry is the world’s largest and fastest growing manufacturing industry. Recent policy changes in India have led to an influx of leading multinational companies to set up electronics manufacturing facilities and R&D centres for hardware and software. This has no doubt helped the Indian economy to grow faster and fueled increase in the consumption rate of electronics products. Along with the economic growth and availability of electronics goods in the market has increased temptation of consumers to replace their household electronics items with newer models for various reasons. The net effect is a higher rate of obsolescence, which is leading to growing piles of e-waste.

The aim of this article is to spread awareness among our readers about the various issues involved in generation and management of e-waste, particularly from Indian perspective.

What is e-waste?

Electronic waste (e-waste) comprises waste electronics/electrical goods that are not fit for their originally intended use or have reached their end of life. This may include items such as computers, servers, mainframes, monitors, CDs, printers, scanners, copiers, calculators, fax machines, battery cells, cellular phones, transceivers, TVs, medical apparatus and electronic components besides white goods such as refrigerators and air-conditioners.

E-waste contains valuable materials such as copper, silver, gold and platinum which could be processed for their recovery.

Is e-waste hazardous?

E-waste is not hazardous per se. However, the hazardous constituents present in the e-waste render it hazardous when such wastes are dismantled and processed, since it is only at this stage that they pose hazard to health and environment.

Electronics and electrical equipment seem efficient and environmentally-friendly, but there are hidden dangers associated with them once these become e-waste. The harmful materials contained in electronics products, coupled with the fast rate at which we’re replacing outdated units, pose a real danger to human health if electronics products are not properly processed prior to disposal.

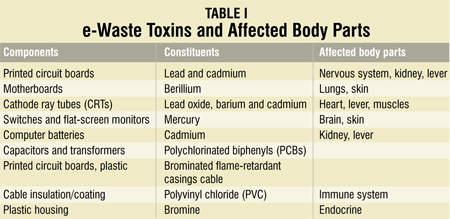

Electronics products like computers and cellphones contain a lot of different toxins. For example, cathode ray tubes (CRTs) of computer monitors contain heavy metals such as lead, barium and cadmium, which can be very harmful to health if they enter the water system. These materials can cause damage to the human nervous and respiratory systems. Flame-retardant plastics, used in electronics casings, release particles that can damage human endocrine functions. These are the types of things that can happen when unprocessed e-waste is put directly in landfill.

The scenario

The Basel Action Network (BAN) which works for prevention of globalisation of toxic chemicals has stated in a report that 50 to 80 per cent of e-waste collected by the US is exported to India, China, Pakistan, Taiwan and a number of African countries. This is done be-cause cheaper labour is available for recycling in these countries. And in the US, export of e-waste is legal.

e-waste recycling and disposal in China, India and Pakistan are highly polluting. Of late, China has banned import of e-waste. Export of e-waste by the US is seen as lack of responsibility on the part of Federal Government, electronics industry, consumers, recyclers and local governments towards viable and sustainable options for disposal of e-waste.

In India, recycling of e-waste is almost entirely left to the informal sector, which does not have adequate means to handle either the increasing quantities or certain processes, leading to intolerable risk for human health and the environment.

Dynamics of e-waste generation

Telecommunications and information technology are the fastest growing industries today not only in India but world over. Manufacturers’ Association for Information Technology (MAIT) has collected the following statistics on the growth of electronics and IT equipment in India:

- PC sales were over 7.3 million units during 2007-08, growing by 16 per cent. There is an installed base of over 25 million units.

- The consumer electronics market is growing at the rate of 13-15 per cent annually. It has an installed base of 120 million TVs.

- The cellular subscriber base was up by 96.86 per cent during 2007-08. Its installed base is estimated to cross 300 million mark by 2010.

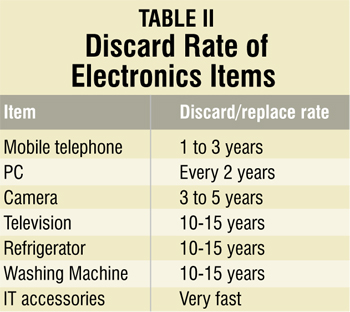

With the unprecedented induction and growth in the electronics industry, obsolescence rate has also increased. People are phasing out/replacing their IT, communication and consumer electronics equipment including white and brown goods as shown in Table II.

As per a GTZ-MAIT sponsored study conducted recently by IMRB, e-waste generated in India during 2007 was around 332,979 MT besides about 50,000 MT entering the country by way of imports. The reasons for generation of this large quantity of e-waste were unprecedented growth of the IT industry during the last decade, and the early product obsolescence due to continuous innovation. Thus the net effect is the e-waste turning into a fastest growing waste stream.

However, the total e-waste avail-able in 2007 for recycling and re-furbishing was 144,143 MT. Of this, only 19,000 MT of e-waste could be processed.

Components of ewaste management

The major components of ewaste management are:

- e-waste collection, sorting and transportation

- e-waste recycling; it involves dismantling, recovery of valuable resource, sale of dismantled parts and export of processed waste for precious metal recovery

The stakeholders, i.e., the people who can help in overcoming the challenges posed by e-waste, are:

- Manufacturers

- Users

- Recyclers

- Policy makers

e-waste concerns and challenges

- Accurate figures not available for rapidly increasing e-waste volumes—generated domestically and by imports

- Low level of awareness among manufacturers and consumers of the hazards of incorrect e-waste disposal

- No accurate estimates of the quantity of e-waste generated and recycled available in India

- Major portion of e-waste is processed by the informal (unorganised) sector using rudimentary techniques such as acid leaching and open-air burning, which results in severe environmental damage

- e-waste workers have little or no knowledge of toxins in e-waste and are exposed to health hazards

- High-risk backyard recycling operations impact vulnerable social groups like women, children and immigrant labourers

- Inefficient recycling processes result in substantial losses of material value and resources

- Cherry-picking by recyclers who recover precious metals (gold, platinum, silver, copper, etc) and improperly dispose of the rest, posing environmental hazards

- No specific legislation for dealing with e-waste at present

Status of e-waste initiatives

The Ministry of Environment & Forests (MoEF) of the government of India is responsible for environmental legislation and its control. The Central Pollution Control Board (CPCB), an autonomous body under the MoEF, plays an important role in drafting guidelines and advising the MoEF on policy matters regarding environmental issues. Historically, in 2001 in cooperation with MoEF, the German Technology Cooperation (GTZ) began work on hazardous waste management in India through the advisory services in environmental management. Subsequently, Swiss Federal Laboratories for Material Testing and Research (EMPA) started to implement its global programme ‘Knowledge Partnerships in e-waste Recycling.’

Combining the knowledge and technical expertise of EMPA on ewaste management, coupled with the field experience of the Indo-German projects in managing hazardous waste in India, the Indo-German-Swiss e-waste initiative was born in 2004. The vision of this initiative is to establish a clean e-waste channel that is a:

- Convenient collection and disposal system for large and small consumers to return all their e-waste safely

- Voluntary system for modern and concerned producers to care for their product beyond its useful life

- Financially secure system that makes environmentally and socially responsible e-waste recycling viable

The objectives of the initiative are:

- Reduce the risks to the popula-tion and the pollution of the environ-ment resulting from unsafe handling

- Focus on knowledge transfer to and skills upgrade of all involved stakeholders through trainings and seminars

- Target mainly the existing informal recyclers allowing for their maximum but safe participation in future ewaste management by facilitating their evolution and integration in formal structures

The milestones achieved so far are:

1. Improved awareness:

- Three WEEE Care! Initiative workshops in Bangalore sup-ported by the Goethe Institute

- National e-waste workshop in Delhi, hosted by MoEF

2. Improved stakeholder engage-ment:

- Formation of the e-waste Agency (EWA) brings together industry, government and NGO to work on a sustainable ewaste management strategy for Bangalore

- First national e-waste workshop held, defined a way forward

- First national workshop on e-waste guidelines held, organised by MoEF

3. Improved estimates of e-waste:

- Rapid assessments in Delhi and Bangalore of the quantities being generated, and identification of the e-waste recycling hot-spots

- National-level desk study to assess e-waste quantities

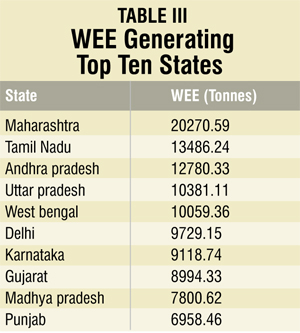

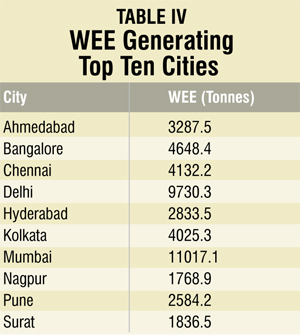

A national-level assessment of electronics and electrical equipment waste (WEEE) by MoEF/CPCB/IRG/GTZ lists the top ten most polluting states and cities of India as shown in Tables III and IV. The figure are taken from the presentation of Dr Dilip B. Boralkar at National Conference on Ewaste Management, an Indo-German-Swiss E-Waste Initiative, at New Delhi on December 10, 2008.

The MAIT-GTZ study on e-waste found that 94 per cent of the organisations studied did not have any policy on disposal of obsolete IT products. Though many respondents (200 corporates and 400 households) were aware of e-waste, they were lacking in action.

Vinnie Mehta, executive director of the MAIT, in his presentation at National Conference on EWaste Management (an Indo-German-Swiss E-Waste Initiative), listed the following legislations that cover different aspects of e-waste:

- The hazardous waste (management and handling) rules, 1998 as amended in 2008 for toxic content—registration mandatory for recyclers

- Municipal solid waste management and handling rules for non-toxic content

- Basel convention for regulating trans-boundary movement

- Foreign trade policy, which restricts import of second-hand computers and does not permit import of e-waste

- Guidelines by Central Pollution Control Board (2008)

The guidelines notified in April 2008 identify and recognise:

- Producers’ responsibility

- RoHS (restriction on hazardous substances)

- Best practices

- Insight into technologies for various levels of recycling

Mehta said that the guidelines explicitly mention the need for a separate legislation for implementing producers’ responsibility. He said that e-waste is ‘distinct’ as it is an end-of-consumption waste while hazardous waste results from a distinct industrial process. The Environment Protection Act provides for separate regulations for waste with ‘distinct’ characteristics—Biomedical Wastes (M&H) Rules 1998, Batteries (M&H) Rules 2001, etc.

Advocating a separate legislation for e-waste, he said that in his recent presentation to members of the parliament he has emphasised that e-waste value chain is rather complex as it involves multiple players—producers, distributors, retailers, end consumers, collection system and recyclers—while hazardous waste chain involves only the occupier/generator and the operator. Recovery of non-ferrous metals and reprocessing of used oil are the only two major activities in hazardous waste recycling, while e-waste recycling involves refurbishment for reuse, dismantling and precious metal recovery, which is a complex process.

[stextbox id=”info” caption=”Structure of the Proposed e-Waste Legislations”]

Title: E-waste (Management & Handling) Rules to be published under the Environment Protection Act

Objective: To put in place an effective mechanism to regulate the generation, collection, storage, transportation, import, export, environmentally sound recycling, treatment and disposal of e-waste. This includes refurbishment, collection system and producer’s responsibility, thereby reducing the wastes destined for final disposal.

Essence: The producer of electrical and electronic equipment is responsible for the entire life cycle of its own branded product and in particular the environmentally sound end-of-life management and facilitating collection and take back.

Responsibility of each element in the e-waste value chain:

- Producers

- Dealers

- Collection agencies/collection Centres

- Dismantlers

- Recyclers

- Consumer and bulk consumers

Procedure for authorisation of producers, collection agencies, dismantlers, recyclers and enforcement agencies

Procedure for registration/renewal of registration of recyclers

Regulations for import of e-waste

Liability of producers, collection agencies, transporters, dismantlers and recyclers

Information & tracking

Elimination of hazardous substances used in e-equipment

Setting up of designated authority to ensure transparency, audit and inspect facilities, examine authorisation/registration, etc[/stextbox]

e-nam (EWA Newsletter for Awareness and Management) in its September 2008 issue has brought out the latest activities of EWA, MAIT-GTZ and others involved in the e-waste field. It has published extracts of an article titled ‘Progress on e-waste, but Too Slow’ by Mini Josheph Tejaswi. The statements of various experts quoted in the article are reproduced below:

Lakshmi Raghupathy, former director in the ministry of environment and forest and an expert in ewaste management, said that governmental regulations should make the producers solely responsible for the entire life-cycle—from manufacturing to recycling—of their products.

Nitin Gupta, CEO of Attero Recycling, said enterprises should be extremely careful and responsible while throwing their unwanted computers and storage devices.

Computer manufacturers in India are slowly getting active in ewaste management. “We are working with all stakeholders in the ewaste management eco-system,” said S. Shankar, director (manufacturing and supply chain) in HP. The company has initiated a three-pronged strategy: partner with e-waste recyclers, build awareness among individual/enterprise customers and work with NGOs, recyclers, collectors and dismantlers.

Anne Cheong, senior service specialist in Dell, said each manufacturer has an individual producer responsibility. “We start from home. We have proper recycling facility in all countries including India. We are exploring that in Karnataka as well.”

Though companies claim they are taking action, many don’t believe enough is being done. “Things are very slow. Corporates are yet to understand the importance of it,” said Wilma Rodrigues, founder member of Saahas, a development organisation. Decisions related to ewaste management, she said, are still taken by junior employees in organisations, with top executives not even looking at it. Almost every company has some mention on its website on ewaste management, but very few are doing anything. The country has twelve authorised e-waste recyclers including e-Parisara and Ash in Bangalore, Tessam in Chennai and Eco-Reco in Mumbai. Ramky Group is setting up the country’s largest integrated ewaste management facility in Bangalore in collaboration with GTZ, while Attero is building an integrated e-waste recycling plant in Utter Pradesh.

D.C. Sharma, vice president of Ramky Enviro Engineers, cautioned that no player should indulge in cherry-picking, collect whatever one thinks is worth and leave the hazardous portions out. Ramky is also building a transfer storage disposal facility (landfill) for hazardous waste at Dobbespet on Tumkur Road.

Finally, through improved ewaste management in the major Indian cities, the e-waste initiatives taken in the country will achieve better environ-mental conditions. Moreover, health conditions of workers active in the e-waste recycling sector will enormously improve at the local level. As an overall effect, the living conditions for the neighbouring population will be better. The already existing schemes of e-waste recycling and material recovery, mainly in the informal sector, will be transformed to transparent and workers- and environment-friendly methods. In the long term, the problem of improper e-waste recycling will disappear due to improved methods, implementation of a take-back system and consideration of the extended producer’s responsibility.

Experience exchange on national and international levels, including know-how transfer, is being facilitated through the various initiatives. Thus, a dialogue platform for Indian and European e-waste experts has been created, opening the doors for future industries to be developed and cooperation activities to be per-formed for technology and knowledge transfer.

I am interested in learning e-waste management techniques. Where to learn and how to start a start-up for digger-gold.

Hi

I had started my own company for e wast management solution..

I m at Mumbai. You can call me. 9820838481.

hi i am interested in learning e-waste management

How to implement the e-waste management in real life? What are the things required for it? Tell us the details of how to make this?

I think in a future E-waste management will be the huge challenge for Indian government as well as manufacturers.

hello

Hi, how can I help you?

Hi,

I am interested to submit a project proposal on recycling of glasses ( obtained from ewaste ) and reuse it developing product for practical purpose.

I am Scientist working in glass melting and technology.

Interested person/group may contact [email protected]/[email protected] (mention subject EWASTE UTILIZATION)

I am from Bihar and I want to implement e-waste management in Bihar as it’s a huge challenge for the Bihar Government to handle such a huge amount of e-waste produced in Bihar each year. Interested ones kindly call or message me on 7004321590.