The robot’s flexibility allows it to navigate through narrow spaces, while its sturdiness is powerful enough to lift haeavy loads with ease.

The gradual rise of automation in today’s factories and warehouses has resulted in robots performing difficult tasks in less time. Usually, they manage to easily navigate through open spaces but find it quite challenging when it comes carrying out a task through hard-to-reach spaces such as selecting an object from a cluttered workbench or operating upon the complex machinery of a car engine.

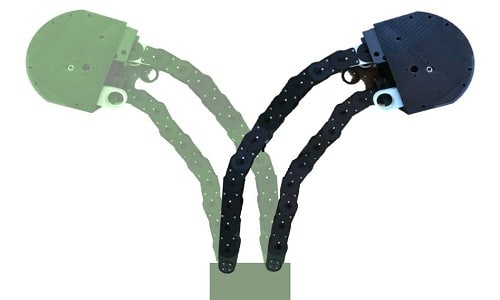

Inspired by how plants grow, engineers at the MIT have developed a robot that has the ability to extend itself in different directions and lengths. With the help of an attached extension mechanism, the robot is flexible enough to twist and turn in any desired configuration, without reducing its capability to lift heavy loads. The robot can extend and retract itself as per the required task.

“The realization of the robot is totally different from a real plant, but it exhibits the same kind of functionality, at a certain abstract level,” says Harry Asada, professor of mechanical engineering at MIT.

Motorised movements

The robot’s gearbox consists of a loose chain of interlocking blocks. Within the box, a system of gears and motors perform the expansion and contraction of the connected chain block units to carry out pick-and-place operations. As the motor rotates the chain around a winch, a second set of motors lock certain block units in place to create a rigid support. The entire system function resembles a growing plant, in which the stem lengthens itself as more and more nutrients are fed to it.

The robot can be programmed to lock together certain units while leaving others unlocked, to form specific shapes, or move in certain directions.

“It can be locked in different places to be curved in different ways, and have a wide range of motions,” says Tongxi Yan, a former graduate student in Asada’s lab, who led the work.

Addition of more external features

The engineers plan to equip grippers, cameras and other sensors onto the robot’s gearbox so that it can move through an aircraft’s propulsion system or grab a product from a packed shelf without disturbing the surrounding arrangement, among other tasks.

Previous robots were made from soft, balloon-type materials that grew like vines in order to squeeze through narrow crevices. However, such soft, extendable robots weren’t sturdy enough to support heavy loads or components such as grippers, cameras and sensors.

“Think about changing the oil in your car,” says Harry Asada. “After you open the engine roof, you have to be flexible enough to make sharp turns, left and right, to get to the oil filter, and then you have to be strong enough to twist the oil filter cap to remove it.”

“Now we have a robot that can potentially accomplish such tasks,” says Tongxi Yan. “It can grow, retract, and grow again to a different shape, to adapt to its environment.”