India has missed the semiconductor bus more than once in the past but with the likes of the United States, South Korea, and Taiwan announcing investments worth more than $200 billion, the opportunity has once again come knocking on the doors. The semiconductors that these countries fabricate will need to be tested and packaged. Is India ready to grab this opportunity? India is best suited as a country for ATMPs and OSATs because of its design capabilities.

Maruti Suzuki, India’s biggest car brand, has had to shut its operations for a while in the country. Similarly, the likes of Volkswagen, Mahindra, BMW, Mercedes Benz, and most other car makers had to either halt or feared possible disruption in their day-to-day operations. The smartphone vertical, one of the hottest investment sectors in India, has also expressed their fear about the same. The common factor behind the fear was not Corona this time but the shortage of semiconductors!

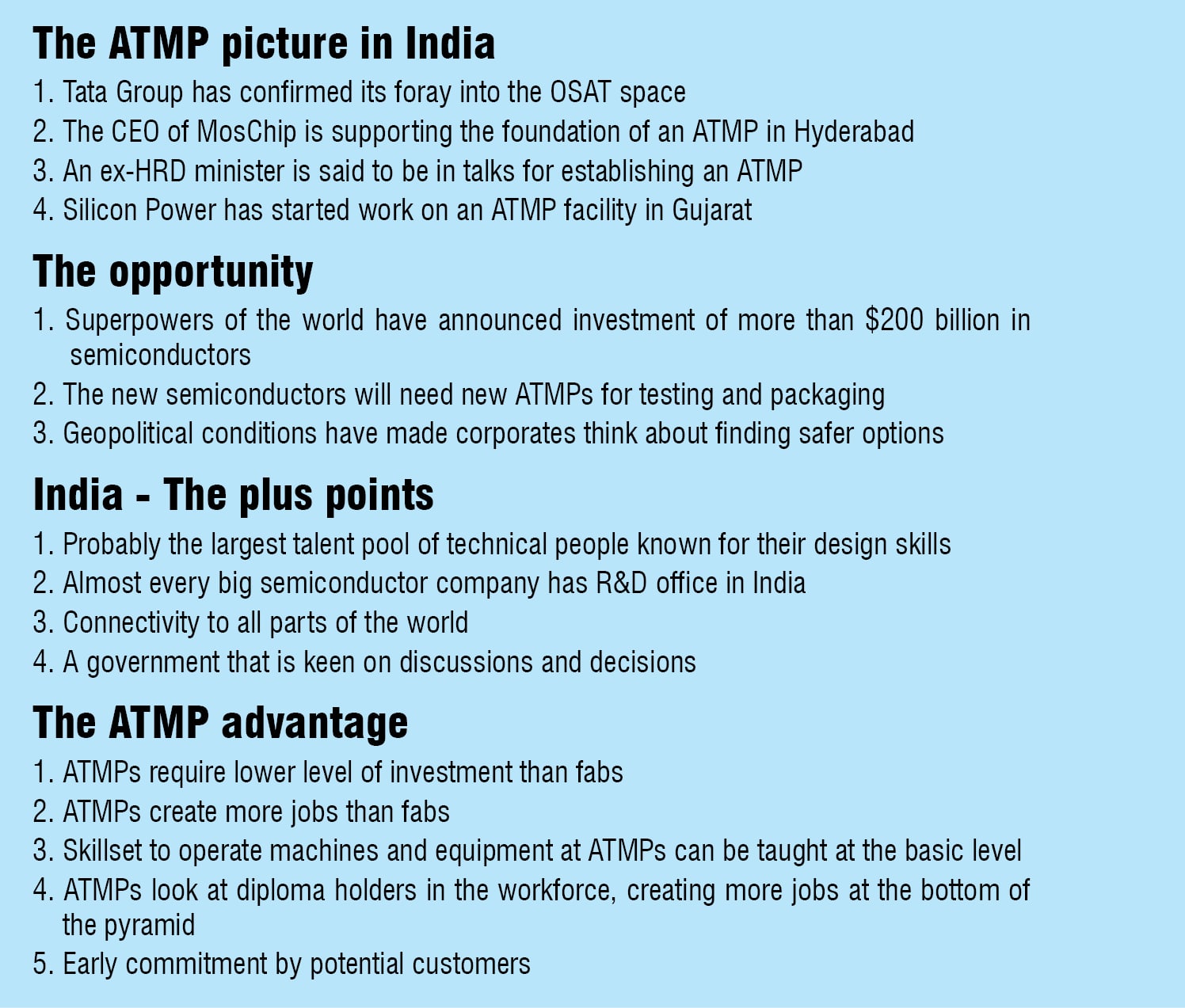

As Prime Minister Narendra Modi has expressed time and again, if India is to succeed it will need to be atmanirbhar (self-reliant). This self-reliance factor weighs a little heavier for the electronics sector because India has very little on plate in terms of semiconductor manufacturing. Efforts have been made in the past, but nothing has taken shape yet. With the current government announcing production linked incentive (PLI) for electronics manufacturing eco-system, hopes have started rising again. India’s first bet in terms of semiconductor manufacturing might originate in the form of assembly, testing, marking, and packaging (ATMP) and outsourced semiconductor assembly and test (OSAT) units.

ATMP and OSAT units require lower investment in comparison to establishing semiconductor fabs, and at the same time can create job opportunities. Experts affirm that such units complement fabless semiconductor companies!

As Poornima Shenoy, former president of IESA and presently CEO of Hummingbird Advisors puts it, “Setting up an ATMP or OSAT could be the right step. The global market for ATMPs is estimated at $32 billion. It is expected to grow to be worth $180 billion by 2028. There are global ATMP firms registering nearly $12 billion in revenue per year already!”

The good news from Tata

Tata Group, one of the biggest corporate houses of India, has already announced its interest in entering the semiconductor space. While Electronics For You was the first media organisation to report about the appointment of Raja Manickam as the CEO of Tata’s OSAT venture, Manickam during the August edition of Tech World Congress confirmed how happy he is to be associated with Tata for bringing the semiconductor ecosystem to India.

“This has been close to my heart. I have been working, living, and breathing semiconductors for the last 40 years,” notes Manickam. Manickam had started a venture by the name of Tessolve Semiconductors in India in 2005. This startup was acquired by Hero Electronix in the year 2016.

Manickam reflected back towards 1995 and explained how he was looking to start semiconductor manufacturing in the country during that time. “The time around 1995 was where I thought there were many opportunities in semiconductor manufacturing and India had already missed the boat. I think the political atmosphere was not right at that time as there were so many adverse situations,” said Manickam.

He added, “I am glad that it is happening now, and I am proud to be a part of it. Tata is a patient corporate house and a visionary industrialist group. I believe that the Tata OSAT is just the beginning of establishing a semiconductor ecosystem in the country.”

The initiative of the Tata OSAT, as per Manickam, has been taken after serious considerations. Despite the fact that establishing an ATMP/OSAT unit does not provide return on investments quickly, Tata Group has gotten into the game considering the long-term and sustainable vectors of the business.

Another good news is that Tata Group is not the only entity investing in establishing an ATMP unit. Dr Harshad Mehta, who heads Silicon Power, is also looking to start an ATMP unit in the country under the banner of Visicon. “Our interest lies in high-power semiconductors. With Visicon the idea is to establish a silicon carbide ecosystem including silicon carbide EPI, silicon carbide processing, and packaging,” explains Dr Mehta.

Dr Mehta has already started working on Visicon’s first facility located in Halol, Gujarat. The facility has bought some equipment and is waiting for more to commence operations. Dr Mehta is hopeful that the operations at the Halol facility will start before the end of this year.

“I really believe in ‘why not?’ and a lot of people might not know that since 2007 we have already been manufacturing power semiconductors in Baroda at a company called Ruttonsha. At Ruttonsha, we focus on power semiconductors,” noted Dr Mehta. It is worth mentioning here that power semiconductors manufactured at the RattanSha facility have been used by the US Army for their power applications.

The third good news is the foundation of ASIP Tech. Venkata Simhadri, who is one of the founders of the ASIP, is also the CEO of a public listed company called MosChip. MosChip was the first fabless semiconductor company established in India.

“I would not say that setting up OSATs/ATMPs is the best way to bring the semiconductor ecosystem to India. However, keeping the current situations prevailing in the country in mind, it is a good way. The same will also help in creating a fabless ecosystem in the country,” says Venkata. ASIP will be located in Hyderabad.

Krishna Moorthy KM, CEO, India Electronics and Semiconductor Association (IESA), recalling a conference hosted by two senior vice presidents (SVPs) of National Semiconductor notes how these two SVPs had encouraged India to start looking at ATMPs first. “India should start looking first at assembly and tests, they said,” recalls Krishna.

The setting up of ATMPs/OSATs is looked upon as a big building block for establishing a robust semiconductor ecosystem. There have been reports pointing towards the consumption of semiconductors touching the magical $500 billion figure, and those figures make test and assembly (which ATMPs and OSATs do) a critical part of developing semiconductors.

The investment required for setting up an ATMP/OSAT is much lesser than what is required to establish a fabrication plant. “It’s very simple economics. The return on investment for a $5 billion investment on a fab will probably take place in five years, but an ATMP will deliver return on investment probably in just three years,” explains Krishna.

A peek into history shows that the first ATMP units were not started as a necessity. In fact, there were no major players involved in the ATMP business during the initial years. None of the big players got into ATMP or OSAT units. “This was something that big players didn’t want to get into during the early days. The view was that this work was better done by someone else as there was no superior technology involved. Moreover, it was more labour-intensive,” says Raja.

Innovation in packaging

Many people, especially in India, view packaging as a lower stack. It’s usually the design engineers that are seen on the top of the totem. The manufacturing engineers are usually placed on the middle or the lower end of the cycle, and the test engineers are seen as the last on the stack. However, Raja is of the view that the real innovation will take place in packaging and testing part. “Tremendous amount of innovation will happen in the test and packaging domain. For example, we are trying to put antennas inside the package. We are doing silicon photonics,” says Raja.

This innovation in packaging is one more reason that explains India’s interest in the domain because the country and its engineers are already well known for their design capabilities. “India is best suited as a country for ATMPs and OSATs because of the design capabilities it has. What started as a dumb manufacturing once has now evolved to engineering-intensive manufacturing, and that makes India the best suited country,” says Raja.

The fact that almost every big semiconductor company of the world has an R&D office situated in India cements what Raja says. The likes of Broadcom, NXP, Samsung, Applied Materials, Micron, and many others have offices located in the country. Intel, as a matter of fact, has its second biggest design centre in Bengaluru.

According to the Department of Electronics and Information Technology (DeitY), nearly 2,000 chips are being designed every year in India, and more than 20,000 engineers are working on various aspects of chip design and verification. More stats by the ministry reveal that the foreign direct investment (FDI) in electronic manufacturing was 1,230 billion rupees (approx. US$18.34 billion) in 2016. It was only 110 billion rupees (appox. US$1.64 billion) in 2014.

But what is the primary reason behind India’s interest in semiconductors? Krishna answers, “It is because the country is facing this much trouble in product manufacturing due to shortage of semiconductors.”

This is a time when even individuals not associated with electronics are asking questions around the shortage of semiconductors, and how soon can India solve that problem. A recent report, mentioned by Krishna, has placed electronics at higher value than gold, and oil is the only item that supersedes electronics as per that report.

Adding fuel to the fire are the geopolitical conditions that have arisen during the last two or three years. These geopolitical conditions involving China and the United States have made the policy makers worldwide, and not just in India, to look for alternatives to their needs. Almost every country is searching for a second option, and this second option has to be a country with high knowledge and understanding of the subject matter, whether it is semiconductors or medical equipment.

“The design ecosystem that India has built looks like a perfect launchpad for what needs to happen next. Fab is at the other end of it but there are things in between that need to happen, and that is why we are talking about ATMPs and OSATs today,” explains Krishna.

There are global design centres located in India that have not limited its designers to the design aspect but have also handed over the architecture of chips to Indian engineers. The practice earlier was entirely different as architects were usually from outside India. The biggest factor, as Krishna notes, is companies like Tata saying that we will have to cut down our production by billions of dollars owing to the semiconductor shortage in the world.

Krishna jokingly adds, “It is all about timing in cricket and semiconductors. You can’t hit boundaries if you do not time the ball!”

Can ATMPs/OSATs make a difference

A lot of professionals, as well as experts sitting in media houses, are of the view that setting up OSATs or ATMPs is of no use unless there are fabs in a country. However, many of these experts often forget that most of the top 20 semiconductor companies of the world are fabless. “Setting up a local OSAT or an ATMP unit can definitely help in fostering a robust ecosystem of semiconductors in India,” says Venkata.

The question that pops up here is that if setting up an OSAT or ATMP can really help then why India has been missing the bus time and again? There have been instances when big names have shown interest in setting up such units but nothing has gone beyond paper and site surveys.

“India has done quite well in terms of mobile manufacturing during the last six years, and with Apple setting up two factories in India, the focus on the electronics manufacturing sector is getting more attention in the country,” says Venkata. He adds, “It is a clear proof that the country now has started believing in its potential. However, the issue is that neither the components nor the semiconductors used in manufacturing these electronics are made in India.”

Additionally, the government of India had recently invited expression of interest from companies interested in setting up fabs in India. However, as per Venkata, that looks like a distant dream. ATMPs and OSATs can make a difference if the industry instead of going after latest technologies goes after use cases, ones that will be the most adopted in India.

“OSAT can definitely be the right start for building a semiconductor ecosystem in India but we cannot give up on bringing or establishing fabs in India,” says Venkata. He adds, “Maybe the five billion dollar fabs can wait but there are other technologies that we should focus on bringing to India.”

The one fact that designers keep in mind while working on new semiconductors is that they are not designing these for just one market but for applications all over the world. Manufacturing of semiconductors is done for the whole world.

“When you build a system you have a microprocessor that will require very state-of-the-art packaging versus other parts that will require different types of packaging. Whatever we do we should always intend to be a global player,” says Raja. He adds, “Hence getting into the ATMP/OSAT story is a great beginning for us.”

Harshad Mehta of Visicon reveals the tidbits about the call he had with MeitY and how the Ministry was of firm view that power semiconductors is the low hanging fruit. The point that differentiates a power semiconductor fab from most other fabs is the fact that a power semiconductor fab requires investment of around $50 to $60 million, which when compared to other fabs is a much lower investment. Moreover, power semiconductors cater to strategic sectors like aerospace and defense.

“The margins are high, there is not much competition, and the power semiconductors are quick in terms of delivering RoI. Power Electronics is a sector where vertical integration is the key,” says Harshad.

Big question: Investment and jobs

India today enjoys the largest amount of FDI. The government has been launching one PLI scheme after another promising billions in the field of electronics manufacturing, and now the talk of India having its own semiconductor ecosystem is gaining momentum once again. But what’s important is whether this semiconductor ecosystem will be able to create more jobs in the country, and how much in terms of investment will it be able to attract?

“Just consider the scale of consumption of electronic components in the country and calculate roughly what that consumption will look like in the year 2025. If we were to produce semiconductors for India to consume in the country (minus the memory), it would require us to establish at least 30 fabs. That is approximately a $120 billion investment. Can we afford such investments in the next five years? Obviously not,” answers Krishna.

Countries including the United States, Taiwan, and Korea have been talking about $200 billion worth of investments for the semiconductor ecosystem during the last three months. It simply means that the world will see a lot more semiconductors being manufactured. Now the question is where will these millions of semiconductors get tested and packaged? The answer, as Krishna pointed out is, “That is the opportunity India is talking about.”

The ideal time for a wafer to come out from the fab and getting ready for shipment is usually 36 hours. Anything more than 36 hours is seen as the ATMP unit losing the game. To enable this time window, the government and the private players will need to work on setting up an ideal infrastructure.

“This infrastructure consists of not only the ATMP units but warehouses at airports, bigger airports, excellent transport facilities, seamless custom clearance abilities, and a lot more. These areas will also help other sectors, will create more jobs, and also attract investment,” says Krishna. He adds, “If we are able to develop this kind of infrastructure, I guarantee that billions of dollars’ worth of investment will come to India.”

In terms of jobs, the challenge does not lie in finding individuals in India but in training people for the right skills. Even 12th pass students can be trained on how to operate machines and equipment at OSATs and ATMPs. That, as per Krishna, is the beauty of having an OSAT.

“The best part is governments are willing to foot the bill. They are willing to have their people skilled for the technologies of the future,” notes Krishna. As a matter of fact, IESA is working on introducing a skilling programme around electronics and semiconductors in the country. The association has plans to open the programme for both engineering as well as below engineering students.

“It is a great time for Indians working on semiconductors outside India to look back at the country. Raja and I have been working on semiconductors for more than 30 years and it took us no time to jump on a plane to come back to India,” says Venkata.

He adds, “It is also a good time to start focusing on ITIs and polytechnics and start helping students for the next wave of modernisation that is set to take place in the country.”

Mukul Yudhveer Singh is a business editor at EFY