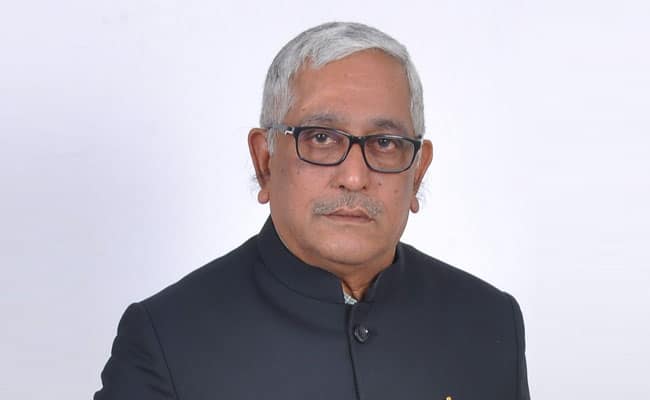

In an exclusive and candid interview with EFY’s Yashasvini Razdan, Jairaj Srinivas, Director General of the Confederation of Indian MSMEs in ESDM and IT (CIMEI), discusses the need for enhanced collaboration, clear policies, effective initiative implementation, skill development, and improved infrastructure to empower the MSME sector, promote local manufacturing, and drive innovation and economic growth in the electronics industry.

Q. Could you elaborate on the challenges for MSMEs in the ESDM industry?

A. Policymakers are grappling with challenges in effectively implementing policies, notably in India’s ‘Make in India’ initiative. While sectors like defence and railways succeeded in promoting local manufacturing, electronics and power industries still heavily rely on imports. Multinational corporations (MNCs) often fail to recognise local manufacturers. For instance, an iPhone charger costing around ₹800-₹2,000 is manufactured locally for just ₹316.

However, these local manufacturers lack original equipment manufacturer (OEM) status, causing uncertainty. Unlike the electronics industry, Maruti’s ‘MGP’ recognises local manufacturers for locally made products. Electronics, however, lack this recognition. Local manufacturers supply chargers to MNCs, which rebrand and resell them. The absence of OEM status hampers local manufacturers and fosters uncertainty. This issue hampers local manufacturing and cybersecurity, as pirated products and software become prevalent.

Further financial challenges impact micro, small, and medium enterprises (MSMEs), particularly post-Covid, as delayed client payments strain working capital. Urgent measures are needed, such as reintroducing a functional bill discounting system. The current system is misimplemented, limiting SMEs’ access to funds. Addressing these challenges is crucial to supporting local manufacturing and sustaining MSMEs’ growth.

Q. Can you tell us how CIMEI helps address these challenges?

A.We consistently and proactively engage with the government and implementing authorities to ensure they promptly address such issues and complaints that land on the CIMEI portal. We communicate the concerns to the relevant authorities, whether from members or non-members. We have been successful in resolving many procurement-related grievances in India. We handle the grievance redressal for procurement procedures in India through NCSI.

We are committed to resolving these problems promptly. We have even challenged MNCs on certain issues, and our efforts have resulted in serious discussions with them. The MNCs have contacted us for further discussions, realising the importance of the matter. It shows that challenging MNCs is possible with strong determination and backed by credible data. We are committed to doing just that, as I will not disappoint my members on any issues.

Q. How can government incentive schemes be made more MSME inclusive?

A. It is evident that the government’s focus on providing relief to the MSME sector lacks clarity and action. In 2020, the government’s decision to instruct all factories to close down resulted in significant production losses, causing a huge financial burden for businesses. Based on turnover and growth, the existing schemes do not seem to incentivise productivity effectively. The productivity-linked incentives that were supposed to be provided have not materialised, and it appears that the government is more concerned with attracting foreign investment than supporting the growth of domestic MSMEs.

Regarding the production-linked incentive (PLI) scheme, the government has disbursed a relatively small amount of funds to a limited number of companies, leaving many businesses without assistance. The conflicting statements from the government and the Reserve Bank of India regarding NPAs and financial support further add to the controversy and uncertainty surrounding the situation. These issues need to be addressed and resolved for the betterment of the MSME sector. Transparency, clear policies, and effective implementation of relief measures are essential to support the growth and recovery of small and medium-sized businesses in the country.

Q. How can supply chain integration be improved to enhance value addition and reduce import dependency in the Indian electronics system?

A. Global electronic products rely heavily on passive components, accounting for about 48% of the components, and active components, which comprise the remaining 52%. The global chip shortage raised concerns, and many governments started working to address this issue. With regard to PCB manufacturing and passive component production, areas like Okhla Industrial Estate, Mayapuri Industrial Area, and Lawrence Road (in New Delhi) contribute significantly to the electronics sector. However, over time, the focus shifted towards importing complete knockdown (CKDs) kits, including PCBs, rather than manufacturing them locally.

This shift impacted the domestic PCB manufacturing industry and led to environmental concerns due to improper disposal of chemicals used in the manufacturing process. India has the capability to manufacture simple components like transformers, capacitors, and transistors, which do not require extensive expertise. By encouraging and supporting local production of these passive components and other critical components like lithium-ion batteries, India can create a self-sustaining ecosystem for the electronics industry, reducing dependence on imports and fostering domestic manufacturing.

The recent announcement by the government to refund 10% of the GST to the state governments for the development of the industry demonstrates the government’s commitment to supporting the electronics sector and encouraging investments. The government and industry stakeholders must collaborate and invest in creating a complete ecosystem for component manufacturing in India. The government should implement proper regulations and encourage the adoption of environmentally friendly practices in the electronics industry. By taking steps to mitigate environmental hazards, the government can strike a balance between industrial growth and environmental sustainability. Leveraging the expertise of organisations like the Federation of Indian Export Organisation (FIEO) and electronic promotion councils can further support and guide the industry.

Q. Can you tell us the prerequisites for creating a high-value addition economy concerning the electronics industry?

A. High-value addition can be achieved only if the percentage of local value addition is increased. While some may claim to have higher percentages of local value addition, the reality is that there is currently only a 6% local value addition. The government needs to take proactive steps to promote local manufacturing and boost the contribution of the MSME sector to the GDP.

In one of his budget speeches, former finance minister, the Late Arun Jaitley, mentioned providing additional benefits for those procuring locally manufactured products, especially accessories like laptop chargers, adaptors, and batteries. The policy aimed to exempt excise duty for big brands that sourced these accessories from local manufacturers. This policy still exists in some form, but it requires better implementation to effectively increase local value addition and strengthen the MSME sector’s economic position.

To achieve high-value addition and drive economic growth, the government should set ambitious targets for genuine local value addition, ideally around 30% over the next five years. This value addition should not be merely on paper but genuinely embedded in the product’s manufacturing process. By doing so, the financial health of the MSMEs will improve, and overall GDP growth will witness positive impacts beyond the current levels.

Q. What stage are we at for skill development and educational programs for creating a high-value addition ESDM industry? What more do we need to do?

A. The Electronic Skill Sector Council of India and the government of India have identified around 14 areas where skill training is needed. Despite the curriculum being established, the primary hurdle lies in motivating trainees to participate. Inadequate infrastructure and workshops pose a challenge in establishing skill training centres, particularly in universities. High investment costs of around five million rupees for even basic training, like PCB soldering, deter businesses due to uncertain trainee inflow.

Corporate social responsibility (CSR) funds are often not effectively utilised, as many companies redirect these funds towards brand-building instead of using them for skill training. This diverts CSR funds from their intended purpose of industry-focused skill development, hindering effective training for those in need. This situation leads to a gap between the skills required by industries and the skills possessed by potential candidates.

Many students lack practical skills. The need for relevant skill training is evident, but some significant barriers and challenges hinder the effective implementation of skill development programs. It is essential to address these challenges and find innovative solutions to bridge the skill gap, ensuring that potential trainees can access the necessary training, and industries can benefit from a skilled workforce.

Q. What stage are we at with respect to research and development for creating a high-value addition ESDM industry? What more do we need to do?

A. Our current spending on R&D in the MSME sector is only 2.5%, which is very low. Small businesses often struggle to allocate funds for research and development due to limited financial resources. However, to foster innovation and growth in the MSME sector, it is crucial to enhance R&D spending. One potential solution is encouraging companies with substantial financial resources, particularly those with significant CSR funds, to invest in R&D initiatives. These companies can contribute to developing common facilities centres and establish contract research organisations catering to various sectors, including the ESDM sector and beyond.

By creating such research opportunities, MSMEs can access research facilities without incurring substantial costs, thereby promoting R&D activities. Ultimately, a high-value addition electronics industry can only be achieved by empowering the MSME sector, as it comprises a majority of the manufacturing enterprises. By promoting collaborative R&D efforts and providing easier access to research facilities, the government can play a crucial role in fostering innovation and growth in the MSME sector. This, in turn, will contribute significantly to the overall development of the country’s economy.

Q. Where are we at, with respect to manufacturing and infrastructure, for a high-value addition economy?

A. We need better industrial infrastructure to support the growth of MSMEs and the manufacturing sector in India to attract investments. The government’s role in providing and improving industrial infrastructure cannot be understated. While some efforts have been made, there is a need for more significant investment and long-term planning to ensure that industrial clusters have access to essential amenities like good roads, rail connectivity, water supply, power, and ICT infrastructure. Offering affordable land with longer lease periods and feasible repayment options can encourage more manufacturers to invest in industrial parks and clusters. This will give businesses a sense of stability and make it easier for them to obtain loans and financial support from banks and other financial institutions.

Moreover, improving industrial infrastructure can also increase employment opportunities in the region and contribute to economic development on a larger scale. By prioritising and investing in industrial infrastructure development, the government can create an environment conducive to growth and innovation in the MSME sector. It will attract more investments, stimulate production, and ultimately contribute to the country’s overall economic prosperity.

Overall, enhancing industrial infrastructure is a crucial step towards realising the potential of the MSME sector and establishing India as a strong global manufacturing hub. It requires a collaborative effort between the government and the industry to address the existing challenges and work towards a more sustainable and competitive manufacturing ecosystem.

Q. What role do startups and entrepreneurs play in creating a high-value addition economy?

A. You have highlighted an essential aspect of the startup ecosystem in India, particularly the need to promote manufacturing startups and provide them with adequate funding support. The startup policy in India encouraged entrepreneurship and innovation across various sectors. While there have been significant developments in the technology and app-based startup space, there is a need to focus on manufacturing startups. The Tata Nano factory example is a significant inspiration for the startup policy. It demonstrated how a manufacturing project can create an ecosystem of suppliers and accessory manufacturers, leading to the region’s job creation and economic growth.

Encouraging more manufacturing startups can have similar positive ripple effects on the economy. Manufacturing startups face challenges due to their capital-intensive requirements, supply chain complexities, and longer gestation periods. To address these challenges, the government and investors should look into providing targeted support and funding to manufacturing startups. One approach could be the creation of specific funding schemes or venture capital funds dedicated to supporting manufacturing startups. This would alleviate the financial burden on startup founders and facilitate the scaling up of their ventures.

Fostering collaboration between startups and established manufacturing companies can enable startups to access the expertise, resources, and market reach of established players, while established companies can benefit from the innovation and agility that startups bring. Providing a conducive policy environment, streamlining regulatory processes, offering incentives, tax benefits, and other supportive measures can also play a crucial role in attracting more entrepreneurs to venture into the manufacturing domain.

By nurturing manufacturing and design startups, the country can diversify its entrepreneurial landscape, create more job opportunities, and strengthen its position as a manufacturing powerhouse on the global stage.

Q. The government is aggressively implementing startup initiatives to promote entrepreneurship. Yet the success rate isn’t a figure we can boast about. Why is it so?

A. The failure rate of startups can be attributed to various factors, including market dynamics, competition, funding constraints, and inexperienced management. The success of startup initiatives and government schemes depends on their implementation and effectiveness. Ensuring that such programs are well-designed and transparent and provide adequate support to budding entrepreneurs is essential. One of the key factors for the success of startup initiatives is the availability of proper mentorship and guidance for entrepreneurs. Many startups lack marketing knowledge and business acumen.

Providing them with mentorship and training in these areas can significantly improve their chances of success. Startup funds and schemes should target innovative and sustainable business ideas. Encouraging startups to address unique problems or cater to specific niche markets can lead to more meaningful and impactful ventures. Government bodies and organisations promoting startups should carefully evaluate each startup’s feasibility and potential impact before providing financial support. This can help ensure funds are allocated to startups with genuine growth potential and a well-thought-out business plan.

Educating aspiring entrepreneurs about opportunities and resources offered by the government and how to access them can encourage more startups to come forward and take advantage of the available support. Angel investors can be a valuable source of capital and expertise, but startups have faced challenges with their investment terms or pressure to generate quick returns. This can create additional stress on the entrepreneurs and affect the long-term sustainability of the business.

Startups in the manufacturing sector may require a longer gestation period before achieving profitability, especially if they involve significant capital investment and research and development. In such cases, entrepreneurs must clearly understand their business model, target market, and growth trajectory to attract the right investors and manage their funding effectively. The transformation of startups into MSMEs can be a significant milestone in their growth journey. However, startups must continue innovating and adapting to market demands even after becoming MSMEs to ensure long-term success.

In conclusion, the startup ecosystem in India, like in any other country, faces several challenges, and requires a multi-faceted approach involving government support, investor diligence, entrepreneurial acumen, and market understanding to create a higher chance of success for startups that can contribute significantly to economic growth and job creation.