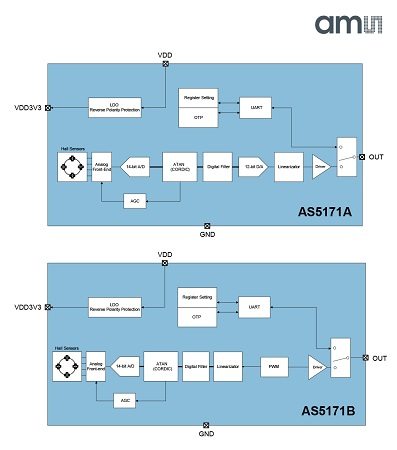

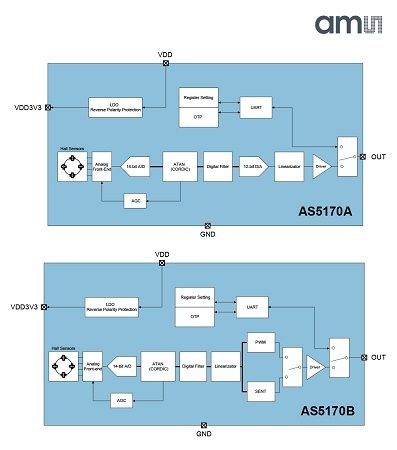

Austria based AMS AG have developed two magnetic position sensor chips, in automotive safety compliant sensors developed using the automotive industry’s programme for ISO26262 safety compliance. The AS5170 and AS5171 sensors were developed as SEooC (Safety Element out of Context) devices. The AS517x parts are magnetic position sensors that provide full data path diagnostics, enabling automotive system OEMs to achieve a higher level of ISO26262 system-level compliance.

The AS5171 comes in an System in Package (SiP) format, which integrates the sensor die and capacitors in a single, encapsulated three-pin package making the entire module very compact. It offers improved ESD and EMC performance along with supply and output pins protection against over-voltages up to +20V. The supply pin also offers -20V of protection against reverse polarity. The analog output AS5170A and digital output AS5170B ICs are housed in an 8-pin Small Outline Integrated Circuit (SOIC) package.

The AS5170 and AS5171 have stray magnetic field immunity, enabling unimpaired operation in the presence of strong magnetic fields. This results in highly reliable performance and reduced system cost, since there is no need for shielding required by other magnetic position sensors. The high sensitivity of the Hall sensor front-end in the AS517x devices enables the use of small, low cost target magnets and supports a wide magnetic field strength input range of 5-90mT.

“The extreme rigor of the automotive functional safety compliance process calls for the use of components which offer total transparency and traceability of their performance and diagnostic outputs”, said Marcel Urban, head of marketing and product management for position sensors at AMS.

“The new AS517x is the first series of magnetic position sensors from AMS to provide for this level of safety support, giving automotive OEMs a more complete set of features than ever before available to enable compliance with the ISO26262 standard.”