At EFY Conferences in March 2017, there was a talk about a new advancement in robotic manufacturing technology, enabling robot workers to be integrated into the labour force to increase productivity and efficiency. Known as ‘Cobots’, which means collaborative Robots, they are a combination of industrial robotics and automation. What led to their success? Read about it in this interview.

Mr. Pradeep David, Country Head, India & Sri Lanka Universal Robots speaks to Dilin Anand from EFY.

Q. What is the most exciting technological advancement in manufacturing?

A. The idea is for humans and robots to be inter-dependent and achieve what each of them does best, safely. There are a few things requiring human ingenuity that are best done manually, whereas the accuracy, precision and repetitive mass production at higher efficiency is best taken care of by robots. These cobots provide an added incentive to the workforce as consistent quality production is possible with human supervision.

Q. What sets these cobots apart?

A. Collaborative robots are lightweight and incredibly easy to operate cost effective and safe to operate. The human-robot collaboration is different from traditional robots. The days of hiring expensive external consulting every time a robot has to be programmed are over. The new reality is operators with no programming experience can quickly program the Cobot arms (with the help of patented, intuitive, 3D visualisation).

Q. How easy is it to use a typical cobot?

A. All we have to do is move the robot arm to the desired waypoints or touch the arrow keys on the easy-to-use touch screen tablets. The cobot arms come with an average payback time of 195 days. That’s the fastest in the industry-quite simply because they are void of all the added costs traditionally associated with automation such as external programming resources and shielded work cells. So automation can no more be considered out of reach now.

Q. What led to widespread adoption of cobots in manufacturing setups?

A. Moreover production setups today often need to be flexible and agile in order to meet changing demand and stay competitive. The light weight cobot arms are easily moved and re-deployed to new processes, enabling you to automate virtually any manual task, including those with small batches or fast change-overs. More than 80% of the UR robots arms in operation worldwide works right next to humans-with no safety guards to shield them and making robot technology accessible to all levels of industry. And cobots are more than happy to do the jobs that human operators find repetitive and dull.

Q. What would you say differentiates normal robotic arms form collaborative robots?

A. If we talk about the traditional robots, Industrial robots are caged to keep humans protected and out of harm’s way. Service robots are meant to safely leave the cage while doing tasks for humans. But collaborative Robots can safely work alongside humans, without any danger of getting hurt, and more as a “worker’s assistant” or “third arm” or “helping hand” or “portable tool” which traditional industrial robots cannot be used as. Collaborative robots come in all sizes and shapes and have integrated sensors and soft and rounded surfaces for safety purposes and to reduce the risk of impact, pinching and crushing. Cobots are “force limited” robots – there is technology built in that allows them to work safely alongside humans (subject to safety assessments of the application).

Q. What is your opinion of the belief that robots will cause additional human job loss in manufacturing?

A. Instead of replacing human and causing job loss, collaborative robots helps companies in expanding operations, thereby creating job opportunities. Cobots help companies to expand multi-fold, thus creating jobs and many more opportunities at supervision roles. In a human-machine study conducted by MIT researchers at a BMW factory, it was shown that teams made of humans and robots collaborating efficiently can be around 85 percent more productive than teams made of either humans or robots alone

Q. Could you elaborate on the communications technologies and protocols used in your robotic arms?

A. Communication technologies and protocols have been used in our robots include TCP/IP 100Mbit, Modbus TCP, Profinet, EthernetIP. All four communication protocols are available for free within each cobot.

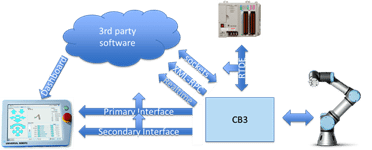

The robot can interact with external devices by different types of communication interfaces.

Primary/Secondary Interfaces

UR controller provides servers to send robot state data and receive URScript commands. The primary interface transmits robot state data and additional messages. The secondary interface transmits robot state data only. The data is mainly used for communication between GUI and controller. Both accept URScript commands with 10 Hz update rate. It makes possible to control robot remotely without robot program.

Real-time Interfaces

The functionality of real-time interface is similar with primary/secondary interfaces. The controller transmits the robot state data and receives URScript commands. The main difference is update rate. The real-time interface updates data with 125 Hz. Dashboard Server

A Universal Robot can be controlled from remote by sending simple commands to the GUI over a TCP/IP socket. This interface is called the “Dashboard Server”. Main functions of the server are to load, play, pause, and stop a robot program, set user access level, and receive feedback about robot state.

Socket Communication

UR robot can communicate with outside equipment through TCP/IP protocol. Data can be transferred via socket communication between robot and other device. In the socket communication, robot acts as client and other device play a role as server. URScript provides commands which open and close sockets, and send and receive different data formats.

XML-RPC

XML-RPC is a Remote Procedure Call method that uses XML to transfer data between programs over sockets. With it, the UR controller can call methods/functions (with parameters) on a remote program/server and get back structured data. By using it, a complex calculation which is not available in URScript can be performed. In addition, other software packages can be combined with URScript.

RTDE (Real-Time Data Exchange)

RTDE is designed as robust replacement for the real-time interface. This allows UR controller to transmit custom state data and accept custom set-points and register data. It runs at 125 Hz update rate.

Q. Are there any analytical or software features in your cobot that prevent it from malfunctioning or causing accidental harm to people around it?

A. Our cobots have over 65 patents pertaining to Robot Safety, Robot Construction, Trajectory Control, and Robot Calibration & Programming. Eighty percent of the thousands of UR robots worldwide operate with no safety guarding (after risk assessment), right beside human operators. The safety system of our robots is approved and certified by TÜV (The German Technical Inspection Association). This is the key which separates industrial robots from ‘Cobots’.

There are 4 types of collaborative operations as per ISO/TS 15066 guidelines on safety. Safety rated monitoring stop, hand guiding, speed and separation monitoring, power and force limiting.

If the robots come into contact with a person, our patented technology limits the forces at contact. The robots can also be programmed to operate in reduced mode when a human enters the robot’s work area and resume full speed when the person leaves. With respect to the hand guiding operation, the human operator uses a hand-operated device and the robot system moves based on motion commands of the operator. It is a kind of manually controlled operation in that the operator is in direct control of the robot system’s operation. This is considered automatic operation, not manual operation.