The government has announced schemes that are promising tens of billions of rupees as incentives for manufacturing electronics within India. The big and small companies, as they start operations in the country, will need a lot of support from the local companies, and these support-providing companies will have a lot of opportunities to establish themselves as big names in the world of start-ups

The government has announced schemes that are promising tens of billions of rupees as incentives for manufacturing electronics within India. The big and small companies, as they start operations in the country, will need a lot of support from the local companies, and these support-providing companies will have a lot of opportunities to establish themselves as big names in the world of start-ups

Rome was not built in a day! While this idiom might have different meanings for different individuals and institutions, for the electronics start-ups ecosystem in India it might stand for the hard work and dedication required to enable them to become the next big thing.

Let us face the fact that setting up an electronics hardware start-up is a far cry from setting up a software or services start-up. Of course, making any of these start-ups successful takes a lot of hard and smart work, but when it comes to electronics start-ups, that hard and smart work requires a little more effort than the rest of the lot.

Look at the number of successful start-ups that have originated in India. The contrast between service and software start-ups and the electronics start-ups will be more than enough to testify to what has been said above.

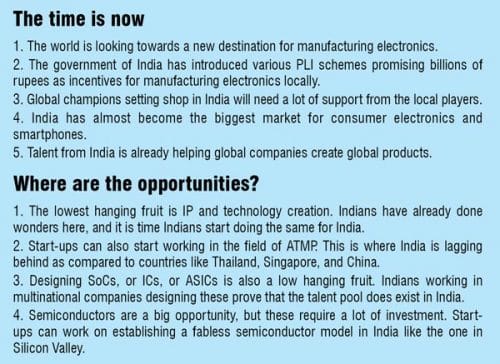

Fortunately, a lot of things have started to change in the country, which are paving the way for the existing electronics start-ups to become successful and are creating room for new electronics start-ups to emerge. Nitin Kunkolienker, president of the Manufacturers’ Association for Information Technology (MAIT), in a recent interaction with Electronics For You magazine group, noted that the recently announced production linked incentive (PLI) schemes by the government of India carry the potential to create an ecosystem for electronics start-ups that the country has never witnessed before.

“A lot of big companies are coming to India for electronics manufacturing. These companies will need support from local players in a lot of things, and this is where the MSMEs and the electronics start-ups can come in. Mark my words, this decade will be the decade of electronics start-ups in the country,” explains Nitin.

The government of India, during the last twelve months, has announced PLI for manufacture of smartphones, air-conditioners, IT hardware products, batteries, and a lot of other products concerning the electronics sector. Though these schemes offer hundreds and thousands of millions of rupees as incentive to global and local companies, the clause that requires production to be desi (indigenous) does spell some big opportunities for MSMEs and start-ups working in the electronics domain.

Where are we today?

The total market of electronics in India in 2019, as per a report by Forst & Sullivan, was approximately $160 billion. The country, as per the report, met the demand for electronics in the same year by importing 50 percent and producing 50 percent locally. While that means that around $80 billion worth of electronics manufacturing took place in the country, we still imported $80 billion worth of electronics that year. But there is a catch to the $80 billion worth of electronics produced in the country.

“The biggest challenge for the electronics sector in India is the low value addition manufacturing that we are doing in the country. This is resulting in the overall valuation of electronics produced in India to less than 17 percent. That simply means that the $80 billion worth of electronics manufacturing we did in India, originally added value of around $14 billion dollars only,” explains Sanjeev Keskar, founder and CEO, Arvind Consultancy.

He adds, “Now imagine a market as big as $160 billion and India getting only $14 billion. It is a very, very alarming situation. What makes the situation grimmer is the fact that the market will evolve to be around $360 billion dollars in the next five to six years. If we continue with low-value addition manufacturing, then the number of components and products we import, and the import bill, will keep on getting towards the increasing side.”

As a matter of fact, India imported 115,000 crore (1.15 trillion) rupees worth of electronics components during 2019-20, and 37 percent of these were imported from China. The bill of smartphone components that the country imported during this time was 56,039 crore (560.39 billion) rupees; 25,441 crore (254.41 billion) rupees worth of such components were imported from China.

It is worth mentioning here that India is the second biggest market for smartphones in the world. In absolute numbers, the country, during fiscal 2020, imported electronics worth 3.7 trillion rupees, according to Statista. The value of electronic products exported from India amounted to 829 billion (0.829 trillion) Indian rupees during the same fiscal.

“Almost 40 percent of an electronic product’s value is made up of the components used in it. These components include semiconductors, PCBs, capacitors, passive components, and a lot of other things. The problem is that 90 percent of these components are imported into India. It also means that the 40 percent market will be difficult to capture in the short term,” explains Keskar.

He adds, “The next 40 percent value comes from IP and technology. This is the area where India has great talent and is doing great work, but the problem is that this talent is either working for a global design centre or in a service company. The number of companies doing innovation as well as manufacturing are just a few! Even smartphones, one of the biggest selling verticals of electronics, do not get designed in India.”

Most of the smartphone manufacturing units in the country import CKD units and assemble them in India before selling them to Indian or international consumers. It is also to be noted here that despite 24 semiconductor companies having their large captive design centres in India, a fabless semiconductor ecosystem, similar to the one that exists in Silicon Valley, is absent in the country.

A report published by NEC and Assocham in 2018 notes that, while electronics manufacturing has been continuously growing since the past few years, the exports have remained constant at around $6 billion in contrast to the imports that have been growing year on year.

“Why can’t we create IPs and technologies that create that 40 percent value. The last 20 percent value is into EMS, packaging, testing, quality, and all other aspects,” adds Keskar.

A lot, rather most of the EMS companies in the country, focus on setting up SMT lines, importing products in the CKD status for assembling and selling them in India. There are also big and small companies that even export these out of India after assembling them here and giving them the ‘Made in India’ tag.

“This is where start-ups can come in, do innovation and become the game changers for the country. The talent that is working in global captive semiconductor design centres can come in and help create a fabless ecosystem for semiconductors in the country. That is how 40 percent of the IP and technology value can be realised within the country and we can do a much better value addition than what we are doing already,” explains Keskar.

There is a strong chance that most of the professionals and institutions will read everything mentioned by Keskar as a big challenge. But these challenges are the ones that are the right set of opportunities up for grabs for MSMEs and electronics start-ups in the country.

The government of India, as mentioned earlier, has already announced many policies focused on electronics manufacturing in the country. While the component manufacturing ecosystem will take around five years, the low hanging fruit—creating IP and technology—can be started to be worked upon from this very moment.

“Creating products and innovation is the need of the hour and start-ups can play a huge role here,” adds Keskar.

Electronics, in terms of import bills, capture the second position after oil. India’s electronics imports, in 2019 were worth $55 billion, and the exports were around $8.8 billion. According to the Commerce ministry, the exports of consumer electronics goods almost doubled to $11.8 billion in 2020 from $6.4 billion in 2018.

The challenges and opportunities

The challenges and opportunities

Though there are a lot of opportunities up for grabs for the MSMEs and electronics start-ups, it still is not going to be a walk in the park for them. The government of India, itself, did not shy away from admitting that the IT hardware manufacturing capability and capacity in the country has progressively declined, and many units have either ceased operations or are operating at low capacities.

One of the PLI schemes reads, “The IT Hardware manufacturing sector faces the lack of a level playing field vis-à-vis competing nations. As per industry estimates, the electronics manufacturing sector suffers from a disability of around 8.5 percent to 11 percent on account of lack of adequate infrastructure, domestic supply chain and logistics; high cost of finance; inadequate availability of quality power; limited design capabilities and focus on R&D by the industry; and inadequacies in skill development. There is a need for a mechanism to compensate for the manufacturing disabilities vis-à-vis other major manufacturing economies.”

And this is just the tip of the iceberg. The government may have been trying to address big companies through such statements, but when it comes to start-ups and MSMEs, these problems amplify! The biggest problem starts with finances, then comes the availability of testing and certification facilities, followed by the availability of components they need, market launch strategies, and various other things.

“The manufacturing disability vis-a-vis China, South Korea, Japan, and some other countries is one of the biggest challenges electronics start-ups face. I think with the new government policies in place a lot of these challenges will be addressed aptly,” feels Keskar.

“I think we are all set to create history. We missed the industrial revolutions earlier but as we enter this new technology revolution that started with the invention of electronics, we are on a point where India can bounce back into glory. We have the right talent. We are the youngest nation in the world, and we will remain like that for the next two to three decades. This is our time,” feels Sanjay Gupta of NXP Semiconductors.

The first and foremost point that the electronics start-ups and the associated ecosystem should look to capture is the creation of IPs in the country. IP creation, as per Gupta and Keskar, is the heart of anything electronic.

An initiative of MeitY to create a ‘fund of funds,’ as per a report by Invest India, will work with venture capitalists (VCs) to promote innovation, IP creation, research and development (R&D), and commercialisation. $101.38 million is committed through EDF to eleven ‘Daughter Funds,’ which in turn will provide risk capital to companies developing new technologies in areas including electronics, nano-electronics, and information technology. The targeted corpus from EDF outlay is $846 million.

Additionally, to position India as a global hub for ESDM and push further the vision of the National Policy on Electronics (NPE) 2019, three schemes—namely the Production Linked Incentive Scheme (PLI), Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS), and Modified Electronics Manufacturing Clusters Scheme (EMC 2.0)—were notified by the government on April 1, 2020.

“IP is one thing but eventually a system-on-chip (SoC), or IC in simple words, is the second overlap over IP. If you can develop IP, there are tremendous opportunities to develop these ICs or ASICs. These are used to solve application-specific problems. We have talent from India that is developing these ASICs for global giants, but we do not have any Indian company developing that in or outside India,” explains Gupta.

The third biggest opportunity for start-ups in the electronics field, as per Gupta, is the ATMP facilities enabling testing and packaging. Companies located near India—including Thailand, China, and Singapore—are super active in establishing such ATMP facilities. However, India seems to be missing this bus as well.

“We are just toddlers into the field of ATMP facilities. I think if we can establish good ATMP facilities, we will be able to add another 20 to 30 percent value in the products,” feels Gupta.

These three opportunities, as Gupta explains, are not just opportunities for electronics start-ups, but these are the challenges that, once addressed, will help enable the dream of making India a hub of electronics manufacturing for the world. And if a semiconductor fab gets operational in the country along with these, that would be the icing on the cake.

“The time right now is presenting the biggest opportunity to anyone and everyone associated with electronics in India. IP creation, IC creation, and ATMP facilities are the three biggest opportunities where we can really start running. We have the talent, we have the opportunity, and it’s time we developed an ecosystem and created history in India,” explains Gupta.

“The time right now is presenting the biggest opportunity to anyone and everyone associated with electronics in India. IP creation, IC creation, and ATMP facilities are the three biggest opportunities where we can really start running. We have the talent, we have the opportunity, and it’s time we developed an ecosystem and created history in India,” explains Gupta.

What can work for start-ups?

An electronics start-up looking to start working on an idea would, on an average, require 1.5 to 2.0 million rupees for purchasing equipment required to start operations. This includes instruments that would be used to test prototypes. Most of the time such investments prove to be big hurdles for electronics start-ups.

“This is where good incubation centres can help electronics start-ups. Good incubation centres have integrated lab facilities that are equipped with most of such equipment and instruments that an electronics start-up needs. Electronics start-ups should be proactive in reaching out to such incubation centres,” advises Sanjeev Chopra, CEO, Electropreneur Park.

Good incubation facilities for start-ups can also help them source components by helping them meet with the right set of people in the supply chain. The value of the right set of components, as per Chopra, is usually realised after start-ups make mistakes in the initial phases of product development and choose components without any consultation with experts.

“A good incubation centre will help you get consultations from experts who have been there and done that before. The right consultation will make their game and the wrong one will break the same,” says Chopra.

He adds, “What if the components you used were at the end of their life cycle? You will simply have to redesign a lot of things once again. As someone looking to create history, this is something start-ups should be looking to avoid.”

A lot of individuals looking to start working on an idea usually do not know about the funds that big corporations park for helping start-ups under programs like CSR. A good incubation centre can help start-ups get access to these funds as well (provided the idea is good). These funds, at the very least, can be used to cover expenses during the prototyping stages. Additionally, the mentors that come attached with such funds are often the kind of experts every start-up dreams of getting mentored from.

“Ideas around electronics start-ups usually fail when the founders are not able to demonstrate the effectiveness of what they intend to achieve. A lot of start-ups, we have realised, have brilliant ideas but they do not pay attention to effectively demonstrating what they intend to do,” explains Chopra.

He adds, “The chances of your start-up getting funded increase if your demonstrations are on the point!”

“The kind of innovation that the Indian start-ups are struck with, unfortunately, is business models. There’s less focus on the technology and more focus on being successful in the short run, sell away the idea and move to another one,” feels Kishor N. Narag, founder and CEO, Narnix Technologies.

He says, “Their only challenge is to find out ways to monetise quickly! Electronics start-ups should always think of remaining in the game for at least five years. If software and services start-ups take three to five years to become Unicorns, electronics start-ups might take one or two more!”

The government of the country has always been under criticism for not offering enough help to the electronics industry. The same government has now announced schemes that are promising tens of billions of rupees as incentives for manufacturing electronics locally in the country. The big and small companies, as they start operations in the country, will need a lot of support from the local companies, and these support-providing companies will have a lot of opportunities to establish themselves as big names in the world of start-ups.

“The global business models are going to witness a sea of changes in the coming times. All nations are delving into their exit strategy from China. As they say, crisis often begets opportunity. This corona crisis is leading to a lot of opportunities. The only question is: Is India ready to grab these opportunities?” says Narang.