Emerging high-efficiency applications require wide bandgap semiconductors for which Silicon Carbide and Gallium Nitride technologies are perfect

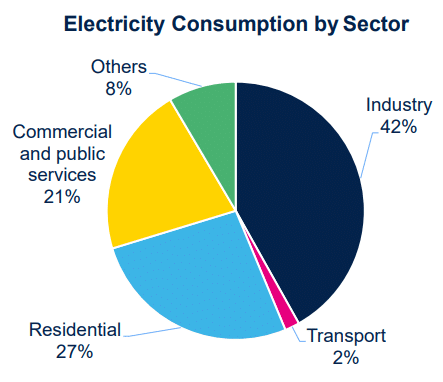

It is expected that the global electricity demand will increase by more than 30% between 2020 and 2030. The increasing energy demands call for better power and energy management to support a sustainable future. A sustainable world means people and our ways of life and our environment are safe. Only when we control carbon emissions by efficient use of renewable energy, can we achieve specific targets laid out for sustainability.

A look at the industrial segment, which is the biggest sector with respect to power consumption suggests that a 1% efficiency improvement translates into a saving of 95.6 TWh. This means roughly 15 nuclear plants or 32 million tons of CO2 can be saved.

| STMicroelectronics (ST) has announced that it will fully become a sustainable, carbon-neutral company by 2027. Its technologies are the basis of a sustainable world and living experience. The aim is compliant to the targets set in Paris in 2021 for restricting the warming temperatures to 1.5 degrees by 2025. |

Importance Of Power Technologies

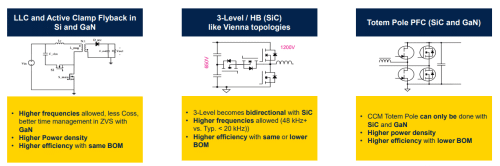

Power technologies are key to achieving better efficiency and saving. The wide bandgap (WBG) technologies are helping with numerous applications to achieve the said targets.Silicon Carbide (SiC) and Gallium Nitride (GaN) offer clear benefits as compared to Silicon technologies. Wide bandgap technology can afford high voltage resilience, achieve faster switching, operate at a high temperature, and reduce heat and power dissipation, allowing improved efficiency and saving. However, SiC and GaN have a few differences that make them more suitable for different types of applications.

SiC and GaN offer clear advantages and benefits to all the steps of the power conversion chain, which includes energy generation, transmission and distribution, storage and conversion, and finally energy consumption. Their characteristics allow implementation of more advanced power technology that is not feasible using silicon technologies.

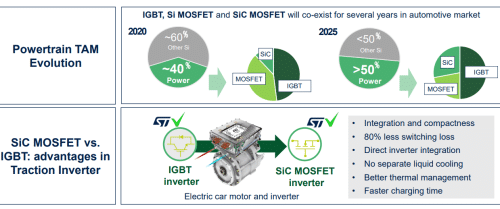

| IGBT is not so interesting in combination with SiC. The first reason is that by definition IGBTs do not have any body drain diodes and this is a limitation. A SiC MOSFET has an integral diode, therefore there is no need to have an external diode as an IGBT. Also, by construction, the IGBT is a bipolar device. So, the switching behaviour depends on the recombination process of electron holes which slows down switching performance, but silicon carbide is adopted also primarily because it can be switched at higher frequencies. |

Application Benefits

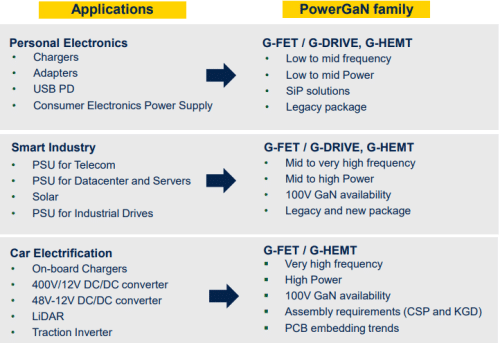

In the automotive domain, including electric vehicles (EVs), the use of Silicon Carbide technology is mostly in traction inverters and powertrains. It is also present in other relevant systems such as charging and DC-DC conversion. This translates into a longer driving range, car weight reduction and improved electric vehicle charging infrastructure. It is known that electric vehicles enable zero emissions, higher efficiency, operability at much lower temperatures and much lower weight. With SiC technology, electric vehicles are simpler to be manufactured and implemented than internal combustion engine-based vehicles.

| The USA has set the target of 50% EV market share by 2030, Europe at 37.5% by 2030 and China at 30% by 2025. General Motors has said that it will sell only vehicles with zero tailpipe emissions by 2035 while Volvo cars has claimed that by 2030, it will become an electric-only company. |

The use of SiC technology in industrial applications, such as power supply for servers and data cloud mining translates into higher efficiency, reduced total cost of ownership, reduced size and weight, compact design and better motor control automatisation. The same is also applicable to renewable energy sources such as solar plants and windmills.

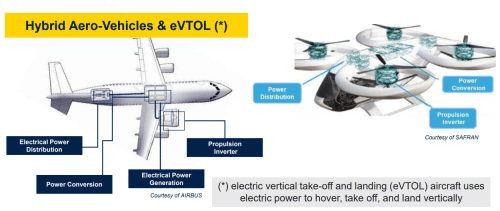

Besides industrial and automotive applications, Silicon Carbide is also being adopted into avionics.

STMicroelectronics’ Initiatives

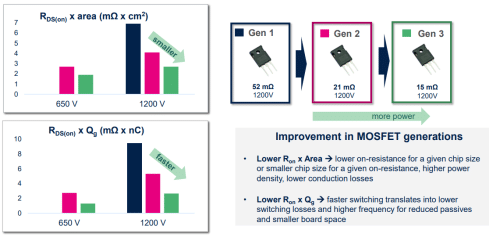

The company is introducing its 3rd and 4th generations to the market. This means by year-end, these technologies will be deployed in the market. Of course, it is not working only on Silicon Carbide technology itself, but coupling it with very deep and strong activity on the packages. To exploit the best characteristics of Silicon Carbide and GaN as well, new package concepts and techniques must be introduced.

Challenges concerning SiC lie in the form of improving the cost of the technology, quality of the material and controlling the defects all over the manufacturing chain. On GaN, one of the issues is to get to complete reliability of the technology and then definitely to bring the manufacturing to the desired level in terms of cost as well.

Silicon Carbide is still a technology in its infancy, so there are still a lot of areas to plan and work upon. The wafer cost is still high, but then there are several techniques to improve that. Together with the substrate cost, the company is looking at epitaxy improvement.

The article is based on a recently concluded online media engagement by STMicroelectronics where the focus was on highlighting the need for sustainability and how STMicroelectronics intends to achieve its sustainability goals for the future.