The junction temperature in a power-handling device rises in proportion to the current consumption. The thermal resistance of the device is important because most electrical components generate heat and need to be cooled. The main goal of the heatsink is to maintain the temperature below the specified maximum operating temperature of the device.

Selecting a heat-sink becomes simpler when you have the datasheet of the device or regulator IC. You can choose it as per the device’s package, requirements, and applications. There are many readymade heat-sinks available in the market. The most common types of heat-sinks for TO-220 package regulators have natural convection cooling with or without fan.

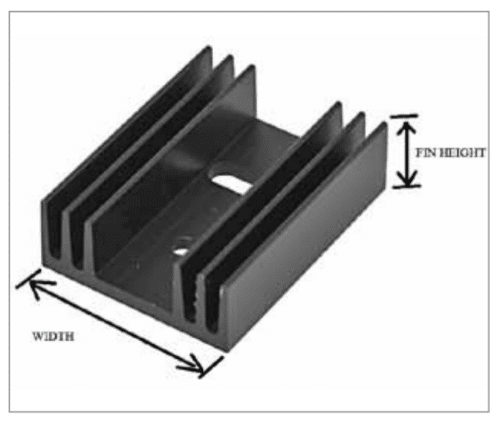

Regulator ICs like LM317, LM78xx, LM79xx, and L200C are available in TO-220 packages. Fig.1 shows width and fin height of natural convection heat-sink for TO-220 package IC. It is an extrusion TO-220 package type heat-sink with the dimension of 35mm×29mm×12mm (length, width, fin height), suitable for use with a device having thermal resistance up to 15.2°C per watt.

Aluminium heat-sinks having large width rather than greater fin height are preferred. Also, if the heat-sink surface is anodised or painted, it increases heat radiation.

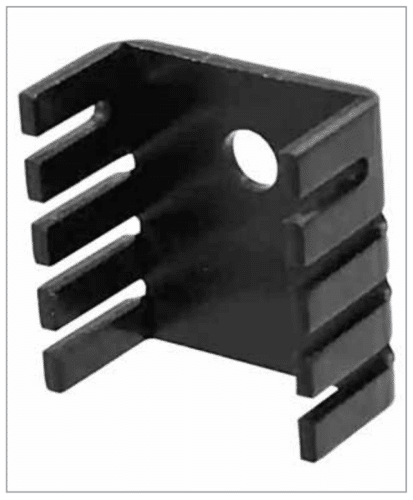

A commonly used heat-sink for 2.5W power dissipation at 60°C and thermal resistance up to 24°C per watt is shown in Fig. 2. It is a black anodised aluminium type heat-sink with dimensions of 19.05mm×19.05mm×9.65mm height.

package