What Is a pump?

A pump is an electrical device that is used for drawing out water to a high level. Basically, a pump works on electromagnetic force. It consists of a motor having a shaft, which rotates at a very high speed. When this shaft is connected to a propeller, the shaft’s rotation causes a pressure difference due to which water gets sucked towards the suction created by the low-pressure area. Hence water from a lower area is lifted to a higher area, causing it to flow. Below, we discuss various types of pumps available in the market.

Types of pumps

There are various types of pumps, which are categorised as dynamic pumps and positive displacement pumps.

Dynamic Pumps

This further includes a centrifugal pump, vertical centrifugal pump, horizontal centrifugal pump and submersible pump.

Centrifugal Pump

The centrifugal pump uses rotational kinetic energy to transport a fluid. The fluid is sucked by the rotating impeller to enter the pump inlet and is then pushed towards the outlet. Here the centrifugal force is used by the impeller. Therefore this pump is called a centrifugal pump.

Types of Centrifugal Pump

A centrifugal pump is classified based on the number of impellers used. It is of 3 types:

- Single-stage centrifugal pump

- Two-stage centrifugal pump

- Three-stage centrifugal pump

Advantage of a Centrifugal Pump

- These pumps can pump harmful liquids.

- Since the motor is placed away at a distance, the heat generated from the liquid flow is isolated from the heat generated in the pump. Therefore less transfer of heat takes place between the liquid and the pump motor.

- Low friction is generated in this type of pump.

Disadvantages of Centrifugal Pump

- Overheating may occur due to lack of liquid during pump operation.

- The coupling can fail in the presence of intense load.

Vertical Centrifugal Pump

Also known as the cantilever pump, this type of pump has a motor located above the ground and connects to the impeller via a long shaft at the bottom of the pump. These pumps are generally used for lifting water from deep underground places such as wells, seawater, groundwater, etc.

Horizontal Centrifugal Pump

This type of pump has two or more impellers. The shaft and the impeller are placed and connected horizontally. This pump is generally used for pumping liquid from containers.

Advantages of Horizontal Centrifugal Pump

- Easy to install

Submersible Pump

This pump has a closed airtight body with a motor so it can work while submerged in the water. The submersible pump eliminates the problem caused by high elevation and inclination.

Advantages of Submersible pump

- Efficient

- Conserves energy

- Works without producing much noise

- The pump is self primed

- Prevents pump cavitation

Disadvantages of Submersible pump

- Due to the use of a gasket in its construction, there is a chance of a leak and internal damage.

- Cost is higher compared to other pumps

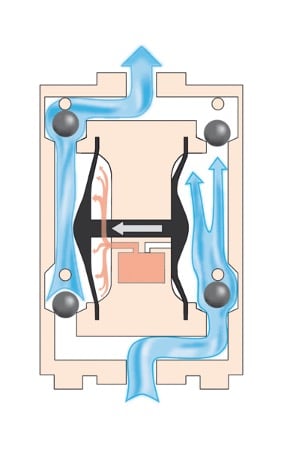

Positive Displacement Pump

In this, the liquid is captured inside the cavity or displaced by the plunger, piston or diaphragm, gears or screws and then is discharged. Liquid flow is regulated with the help of pump speed. A fixed volume of liquid is sucked by the piston or diaphragm and then discharged by the pump.

The positive displacement pump is of the following types

- Diaphragm Pump

- Gear Pump

- Peristaltic pump

- Piston Pump