Whether it be climate change caused by global warming or huge electricity bills of your house, LED lights are the answer to all your worries. Already being used widely, these are definitely going to replace the lamps that we use today.

Light-emitting diodes (LEDs) are small but powerful devices in terms of their diverse applications. LED lights assume greater significance in the context of need for electrical energy conservation and pollution control the world over. These are used as indicators in various equipment, for lighting and decorations at homes, and in flashlights, signboards and car lights.

LED lights differ from traditional light sources in the way these produce light. In incandescent bulbs, a tungsten filament is heated by an electric current until it glows or emits light. In fluorescent lamps, an electric arc excites mercury atoms, which emit ultraviolet (UV) radiation. After striking the phosphor coating on the inner side of the glass tubes, the UV radiation is converted into visible light and emitted. On the other hand, LEDs are diodes made from semiconductor materials. This is why these are referred to as solidstate devices. They rely on indium-gallium nitride to convert electricity into photons when current flows through it.

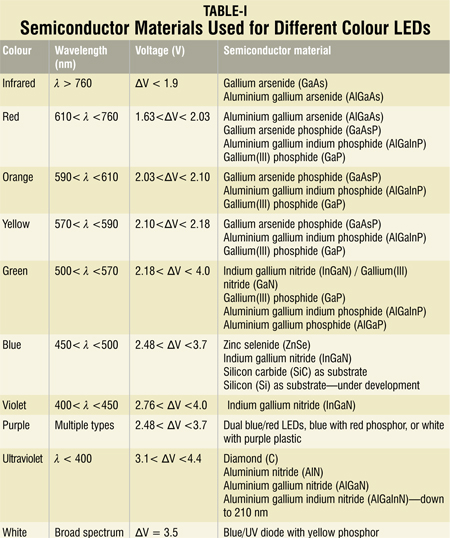

An LED is basically a small-area source, often with extra optics added to the chip that shapes its radiation pattern. The specific wavelength or colour emitted by the LED depends on the materials used to make the diode. It depends on the composition and condition of the semiconducting material used, and can be infrared, visible or near-ultraviolet.

LED-based light technology is a subject of intense research and development. It is predicted to radically change the energy consumption patterns throughout the world over the next few years. Therefore a phenomenal amount of resources are being devoted to improve the LED technology worldwide. The US has committed a large amount of industrial policy support for R&D on LEDs. Asia is a hot bed of cutting-edge manufacturing technology, and Europe and Canada have led the way in energy-efficient initiatives accompanied by some of the most innovative design styles.

How does an LED work?

Light generates inside the semiconductor chip when current flows across the junction of different material compositions. An LED consists of two elements of processed semiconductor material called p-type and n-type semiconductors. These two elements form a p-n junction when placed in contact with each other. The material composition of the p- and n-type semiconductors determines the colour of light generated.

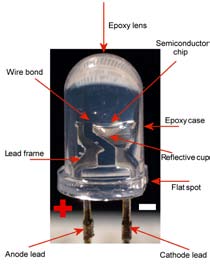

Fig. 1 shows the parts of a common type of LED structure. There are major differences between LEDs and other diode types. An LED has a transparent package, allowing visible or IR energy to pass through. Also, the LED has a large p-n junction area whose shape is tailored to the application.

The device shown in Fig. 1 is an AlGaInP LED because the semiconductor layers are aluminium (Al), gallium (Ga), indium (In) and phosphate (P). It is illuminated with the movement of electrons in the semiconductor material, when an electric current passes through it.

Connecting, soldering and testing LEDs

LEDs must be connected the correct way round. A simple way to identify cathode is the short lead, and the body of round LEDs may be slightly flat towards cathode. If you see inside an LED, you will notice that the cathode is the larger electrode.

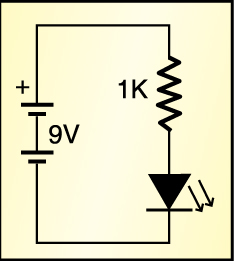

LEDs can be damaged by heat while soldering. So you have to be quick enough to ward off this small risk. Never connect an LED directly to a battery or power supply. It will destroy almost instantly because too much current will pass through and burn it out.

LEDs must have a resistor in series to limit the current to a safe value. For the purpose of quick testing, a 1-kilo-ohm resistor is suitable for most LEDs if your supply voltage is 12V or less.

Materials used for production

LEDs are usually built on an n-type substrate, with an electrode attached to the p-type layer deposited on its surface. Many commercial LEDs, especially GaN/InGaN, also use sapphire substrate.

Most materials used for LED production have very high refractive indices. This means most of the light reflects back into the material at the material/air interface. Therefore light extraction is an important aspect of LED design and production. It calls for a lot of R&D work.

Conventionally, LEDs are made from a variety of inorganic semiconductor materials. Table I shows the available colours with wavelength range, voltage drop and material used.

Why use LEDs for lighting?

After going through the following parameters of LED lights, you’ll find that LEDs are the best solution for energy-efficient and pollution-free lighting.

Lifetime

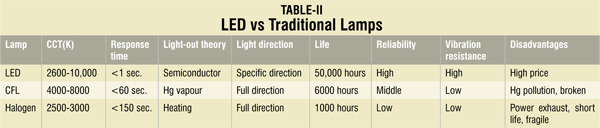

As a solidstate light source, LEDs have a very long lifetime and are generally very robust due to no mechanical or moving parts. Incandescent bulbs have an expected lifetime of 1000 to 5000 hours, while good-quality LEDs can last up to 50,000 hours—more than five years of continuous use.

Low maintenance

The long lifetime of LEDs reduces the need to replace failed lamps, and this can lead to significant financial and environmental savings, particularly in maintenance, labour and recycling.

Efficiency

As a semiconductor device, LEDs are highly efficient. Current device technology is allowing their performance to be pushed to limits that exceed that of standard lighting. The directional nature of light produced by LEDs allows the design of luminaries with higher overall efficiency.

Low power consumption

The low power consumption of LEDs leads to large energy savings.

Brightness

Light outputs of LEDs are constantly being increased, and there are several products that have higher lumen output than traditional lighting.

Heat

Almost 80 per cent of the energy consumed by LEDs is converted into light and only some of it is dissipated as heat.

Small form-factor

LEDs are very small. Typically, high-brightness LED chips measure 0.3×0.3 mm2, while high-power devices can be 1×1 mm2 or larger. There are many examples where the availability of small, high-brightness devices have enabled significant market advancement. One obvious example is mobile phone handsets, where blue, green and white LEDs are now used in most models to backlight keypads and liquid-crystal display (LCD) screens.

Instantaneous switch-on

LEDs switch-on rapidly, even when cold, and this is a particular advantage for certain applications such as vehicle brake lights. These light up very quickly and achieve full brightness within a few microseconds.

Colour

LEDs are available in a broad range of brilliant, saturated colours. White devices are also available.

Also, LED lights are shock-resistant, and a solid package of the LEDs can be designed to focus their light. The fact that LEDs are non-toxic (do not contain mercury) also favours their application.

On the downside, in many applications, LEDs prove to be expensive compared to other light sources. However, LED manufacturers are working towards reducing their cost.

LED applications

LED applications can be categorised into visual signal applications (where the light moves from the bulb to the human eyes directly), illuminations (where LED light is reflected from an object to give visual response) and technological (which don’t require contact with the human visual system as in the case of light photosynthesis in plants).

LED lights are being used in many areas, such as LCD screens, mobile phones, iPods and safety and security hardware. LED technology is vast and growing by leaps and bounds. The newest trend in the electronics market is the green influence that has not left the LED world bereft. The most recent launches in the LED market are the light bulbs that can help you save up to 90 per cent of electricity costs and reduce the heat output. Moreover, these bulbs are claimed to last up to ten times longer than a standard light bulb or compact florescent light. Some of the most advanced LED-enabled products in the electronics world are LED jellyfish mood lamps, Sony Walkmans and hydroponic LED lights.

LED jellyfish mood lamps

These are unique desktop tanks that trick your eyes into believing that three jellyfish are swimming, with the aid of six bright colourful LEDs that are placed at the top of the tank.

Sony’s Walkman

Sony has launched a Walkman called NWZ-X1000 that features an organic light-emitting diode (OLED) touch-screen.

Hydroponic LED lights

Growing plants indoor with a hydroponic system is becoming popular. Plants take the light and turn it into energy through the process of photosynthesis. This is not just an option but a necessity and will ensure that you have plants that thrive and give you the results that you are looking for. Luckily, there are ways to fool plants into thinking that they have been given all the light they need, and for this you can use LED lights.

LED lighting is also used for security reasons and as traffic lights. Since these lights consume very little power, they are ideal for long running operations or where the lights are required to remain on for an indefinite time period.

Basically, LEDs are available in three categories

LEDs for cars, LED flashlights, and LED bulbs or strips for home. LED tubes with different patterns are also becoming popular. LED rope light for household use is yet another wonderful light that you can use for home décor. These lights look pleasing to the eye and can be used to outline the boundary of an object.

LED car kits are admired by a lot of car enthusiasts all over the world. These LED lights create an under-car halo. LED car kits require 12V power and come with 2.1-million colour output. These can display one colour at a time and the pattern can be chosen according to the terrain or situation. The lights are waterproof and can last for years to come.

LED lights can be as simple as a matrix of LEDs with resistor, or high-power multipurpose LEDs that are strong and long-lasting. These are designed to operate non-stop for long durations because of extremely low power consumption and very little heat dissipation. They are ideal to be used as ambient and architectural lights as well as medical and convenient lights.

The ‘cold’ generation of LED light leads to high efficacy because most of the energy radiates within the visible spectrum.

According to the research statistics, the response time of a person viewing an LED brakelight is quicker than brake lights powered by incandescent lights, and it can add 4 to 6 metres of safe distance while you are driving through the superhighway. Many domestic and international automobile manufacturers are already using LED-powered brake lights, appearance lights and floodlights.

How to design an LED module?

The ‘LED Street Light Design and Development’ article by Tsung-Chieh, Chen, from System Integration Development Division of Alliance Optotek Corp. (AOP), Taiwan, describes the various design considerations for LED modules nicely. Extracts from this article are reproduced below:

“Since there exist obvious differences between LED and traditional lamps, the thermal, optical, power mechanism and control become very important as one designs LED lighting products.

“In the past two years, LED street lights have been widely discussed since there exists a very large market and the LED’s power saving performance is obvious especially in replacing the 250W or 400W mercury lamp. To build an LED streetlight, Alliance Optotek Corp. of Taiwan has analysed the key issues to meet the specifications such as guarantee of five years’ LED life, light pattern to meet the roadway regulation specification, dust and water-resistant specifications, etc. Based on these qualitative requirements, to design the LED streetlight, one needs to consider the thermal, optical and power mechanism design strategies.

“It is known that the LED life depends on the LED junction temperature. Cree, another major manufacturer of LEDs, has announced data to show the relationship of life versus maintenance of different junction temperatures. Therefore, to guarantee five years or 50,000 hours of life, the LED junction temperature has to be controlled under 75°C.

“As for the illumination uniformity of roadway, use of the batwing light pattern design of AOP is inevitable. The cut-off light pattern for glare limitation is also required. The other important subject is both the driver (power) design and the LED light module design: We know that each LED has a little different drive voltage and we can not guarantee the same drive voltage for all of the LEDs that have been built into the streetlight. So a worse circuit design will induce a non-uniform current to drive the LED, which will impact the LED’s life.

“AOP knows all of the design issues that will directly affect the quality of the LED streetlight product, hence it combined thermal, optical, power and mechanism to do an overall design that ensures streetlight quality.

“So an excellent LED lighting product has to consider: thermal, optical and power mechanism (industry design).

Thermal design

As it is known, the higher the LED junction temperature, the shorter the LED life-time. To guarantee 50,000 hours of life-time, AOP has designed a streetlight in which the LED junction temperature is controlled under 75°C and heatsink temperature variation is constrained below 2°C to ensure that all of the LEDs applied on the streetlight reach the same life. They found a reasonable heatsink size to reach the design target, LED junction below 75°C and heatsink temperature variation under 2°C.

LED street light optical pattern design

As mentioned above, if the streetlight is meant for roadway application, then it needs to meet roadway illumination specification, i.e., the optical pattern has to meet the uniformity of illumination and glare rating. To meet the roadway regulation specification, how to let the light output project on the large roadway area is also important.

To meet the specification of mounting height of 6 metres, correct distribution of the light output along the 18m roadway length was necessary. So, as there existed a specific length, the roadway needs to install streetlight. Then you need more streetlights to apply to meet the roadway specification and avoid the zebra pattern appearing.

This case study for an AOP streetlight installed on 8m pole height, and projected on 32m roadway length, claims that optical pattern can largely reduce the streetlight installation quantities as on a specific roadway length.

Power mechanism and industry design

In AOP’s streetlight, they also considered the moving and installation convenience. In the power space, they have installed a socket, so the operator can easily install the city cable into the socket and this process is the same as the traditional lamp installation. By the way, the bow-shaped design in the front of the luminaire can let the operator easily move. This luminaire is dust- and water-resistant and its rating reaches the design goals for LED light module and driver power design.”

Continuing development

The efficiency and light output of LEDs are doubling about every 36 months since the 1960s—in a way similar to Moore’s law. The advances are generally attributed to the parallel development of other semiconductor technologies and advances in optics and material science. This trend is normally called Haitz’s Law after Dr Roland Haitz.

The first high-brightness blue LED was demonstrated by Shuji Nakamura of Nichia Corporation and was based on InGaN.

Around 1999, Philips Lumileds introduced power LEDs capable of continuous use at one watt. These LEDs used much larger semiconductor die sizes to handle the large power inputs.

The efficiency of LED-based lighting is measured by its light output per unit power input. White LEDs quickly matched and overtook the efficiency of standard incandescent lighting systems. In 2002, Lumileds made 5W LEDs available with a luminous efficiency of 18–22 lumens per watt.

In September 2003, a new type of blue LED was demonstrated by Cree, Inc. to provide 24 mW at 20 milliamperes. This produced a commercially packaged white light giving 65 lm/W at 20 mA, becoming the brightest white LED commercially available at the time, and more than four times as efficient as standard incandescent bulbs. In 2006, Cree demonstrated the prototype of a white LED with a record luminous efficiency of 131 lm/W at 20 mA.

Seoul Semiconductor had planned for 135 lm/W by 2007 and 145 lm/W by 2008. Nichia Corporation has developed a white-light LED with luminous efficiency of 150 lm/W at a forward current of 20 mA.

It should be noted that high-power (≥1W) LEDs are necessary for general lighting applications. Typical operating currents for these devices begin at 350 mA.

Cree is reported to have developed an LED prototype achieving 161 lumens/watt at room temperature. The total output was 173 lumens, and the correlated colour temperature was reported to be 4689K.

Market forecasts

Over the past few years, the light-out efficiency of LEDs has largely risen from 35 lm/W (2006) to 100 lm/W. With their efficiency increasing, LED products that replace traditional lighting have been well anticipated, especially in high-power-consumption products.

Global demand for electric lighting is forecast to reach $40 billion in 2012 on annual gains of more than seven per cent. The emerging economies of China, India and Russia are projected to be the fastest growing markets for electric lighting products through 2012. Driven by rising incomes and rapidly growing non-residential construction, these three nations will account for 40 per cent of the additional demand generated between 2007 and 2012. The greatest gains will come from China.

LED lighting devices are forecast to become the fastest growing products in every regional market over the forecast period, as these products continue to penetrate both the construction and manufactured goods markets. Gains will be particularly fast in the Asia-Pacific region, where demand for LED lighting is expected to nearly double between 2007 and 2012.

Indian scenario

In India, a number of companies are manufacturing/marketing LED lights in Mumbai, Delhi, Chennai, Kolkata, Bengaluru, Ahmedabad and other major cities of India. These include Binary Opto Electronics Pvt Ltd in Kolkata and Kwality Photonics Pvt Ltd in Hyderabad.

GlacialTech, a company engaged in LED lighting business, sees big growth potential. According to a company spokesperson, “The percentage shift from traditional lighting to LED lighting depends on improvements in the LED chip technology and lowering of the manufacturing cost. But, we have already seen this transition happen, and it will be quicker from this year.”

GlacialTech expects over 80 per cent CAGR (compound annual growth rate) in the next four years.

White LEDs for home lighting offer great benefits for the far-flung tribal villages of India. This technology was first implemented in the state of Andhra Pradesh to provide low-cost, long-lasting, renewable energy home lighting systems for poor villagers. Small solar panels can be used to produce enough energy to keep these LED lights burning for hours in rural huts. This will trim down the dependence on kerosene lanterns for lighting.

The author is a consultant and technical head with EFY at Delhi