As the name suggests, MRO activities involve fixing any sort of electrical, plumbing or mechanical device once it breaks down or becomes out of order. It would also include, what we can call, scheduled or preventative maintenance. A common problem for many manufacturers in servicing equipment is to track and ensure that the maintenance engineer arrives at the correct site, is supplied with the correct servicing information and is working on the correct machine. Additionally with the demographic challenges, manufacturers are increasingly concerned about how to better utilise the skills of the existing workforce.

The mobile maintenance, repair and operations (MRO) prototype is designed to help manufacturers and companies supplying and maintaining high-value machinery in sectors such as shipping, oil & gas and aerospace. This tool that is being developed will mean engineers can go on-site with the confidence that they will have instant back up from the experts. This will enable in increased capacity to respond to the demands of industry more quickly, more cheaply and with a higher level of confidence than before.

Smart Mobility in MRO

Today, MRO tasks typically involve an engineer visiting a site, finding the right machine, and making sure they have an appropriate task sheet. If they run into difficulty, they might call for help from a product expert or remote supervisor. The mobile system, using a combination of augmented reality and robotics, will help field engineers accurately locate equipment, provide them with critical information and receive real-time visual support from supervising experts located remotely. This system also allows a supervisor to monitor an engineer’s progress towards the maintenance site using GPS.

Once on site, an engineer can use a smartphone and QR codes to locate and identify an asset and receive maintenance instructions. The smartphone uses augmented reality technology to overlay points of interest over a plan of the site, which can include the location of other engineers, first aid stations and health and safety apparatus.

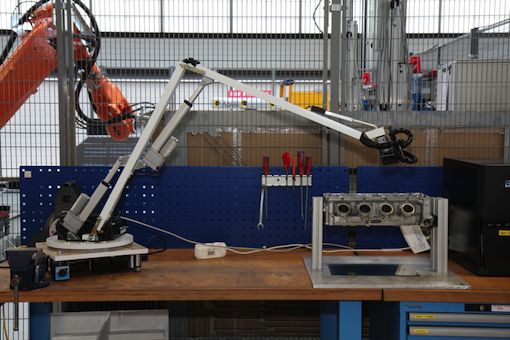

If assistance is needed, a remote expert is able to view the on-site engineer’s workspace and support them with real-time video and audio links using a camera and a small projector mounted at the end of a remotely controlled robotic arm. The expert, from his management console, is also able to project a pointer and valuable information such as free-hand sketches, assembly instructions and CAD images directly onto the workspace or a nearby wall.

The benefits of this smart MRO prototype is that it is designed to be transportable and hands-free, enabling the tracking of engineers, transmitting the captured video and supervises gestures over the network. So the engineer would be able to situate it anywhere needed and use both hands to interact with the object. The smart MRO prototype is an example of innovation being built on proven technologies from the IBM labs and is adaptable for machine support and assembly activities. The prototype also enables video capturing for training and systems assurance thereby reducing cost of operation.

It offers manufacturers the opportunity to lower their costs, provide just-in-time knowledge transfer and reduce the personal risk to engineers working in difficult environments.

Studies have shown that remote support is much more efficient if on-site and remote engineers can share a visual representation of the site workspace and the on-site engineer’s actions. To date, this has been accomplished, and only in part, by on-site engineers using hand-held cameras, mounted head-gear or specialist glasses. The new system provides the supervisor with complete visual independence and a more stable video image; on-site engineers are able to work with greater freedom or, in the case of those with specialist glasses, freed from the tiring need to re-focus their eyes.

An AMRC IBM Collaboration

The project is the result of a collaboration with the University of Sheffield Advanced Manufacturing Research Centre (AMRC). The AMRC is responsible for identifying, researching and resolving advanced manufacturing problems in order to help businesses become more competitive through the application of new techniques, technologies and processes. It is part of the High Value Manufacturing Catapult, a network of leading manufacturing research centres backed by the UK government. Dr Rab Scott, head of the Virtual Reality and Modelling Group AMRC, said, “IBM’s MRO prototype is an exciting addition to the innovative toolset used by the AMRC’s researchers and engineers. We hope to demonstrate its usefulness and versatility in a number of situations within the manufacturing arena.”

The new system exemplifies how a new wave of mobile computing is revolutionising they way businesses can transform their processes. Data from existing back-end systems is increasingly placed in the hands of front-line employees. Social media too is transforming the way employees are able to interact, by extending the reach of organisational expertise at minimal cost.