The power management and reduction segment of component industry is looking out for new technologies to satisfy the tremendously growing demands for lightweight, small devices that run forever. Let us take a look at what’s new and trending

Anagha P

Energy crisis is an important issue in today’s world and embedded designers across the globe are focussing on development of systems with reduced operating power consumption and increased system performance. There are a large number of applications that have relaxed efficiency and power loss requirements. However, in many markets we find that consumer desires and government regulations continue to drive trends in the power sector.

“The power to innovate begins with power,” says Esmond Wong of Arrow Asia Pac, “because electronic designs must be created with power in mind.” Consumers demand small, light and longer-battery-life devices with more features. The way power is managed plays a major role in the design of any embedded system, as it has a direct impact on battery life, performance, size and cost of the product. Each new feature added to the device increases its power consumption. But one should not introduce bulky power supplies or batteries to the system either. All these issues are fuelling the intense research and development in power reduction and management.

A device that dissipates power unnecessarily requires larger power supply to operate, hence increasing the size and cost. Moreover, whatever power is consumed by the device turns into heat, creating secondary problems. Accordingly, there arise requirements for heat sink and airflow in the application. All these add to cost, increase size and, in extreme cases, can even pose a threat to the system. Hence, power efficiency is a key product differentiator for embedded systems.

Trends in power sector

Modern power management designs require more sophistication than traditional supply conditioning and distribution. For example, powering-off unused functions, except when these are needed, is critical to stretch battery life in portable products. Here are some trending features in the power sector, according to our spokespersons:

Efficiency. The most prominent drive in power conversion is efficiency improvement, according to experts at Microchip. Several applications moved from linear regulators to switching power supplies to increase efficiency. Many manufacturers, like Microchip, have released a variety of components that create more efficient power converters.

However, with increasing efficiency of components and devices, marginal efficiency improvements become lesser and system cost increases. Due to this reason, in many cases, the goal has evolved to reducing the power needs of an application as a whole, instead of focusing on the efficiency of individual parts.

Integration. Just like in many other sectors in the industry, integration trend has come up in power management too. It not only improves performance and reduces integrated chip (IC) size, but also makes power supply design much more manageable during tight design and product cycles. Integration trends, especially of dissimilar technologies like power metal-oxide semiconductor field effect transistors (MOSFETs) or ICs with gate drivers or controllers, and even passive components, are casting an increased focus on packaging technology.

3D packaging technology. In this method, ICs are stacked vertically or tiled horizontally in a single package. This technology is also known as system-in-package (SiP) or chip stack MCM (multi-chip module). It provides high levels of silicon integration, offers increased design freedom, increases area efficiency and reduces the length and size of interconnect architecture, thereby reducing power requirements, form factor and cost, significantly.

Power density. Data centre space is limited and, as a result, the server power conversion density has to go up, that is, the same operation should be performed in lesser space. In order to achieve this, power distribution will be simplified from current three-stage structure (rectifier → inverter → single-phase power factor correction) to two-stage structure (three-phase power factor correction front-end → high voltage direct current bus).

In the market

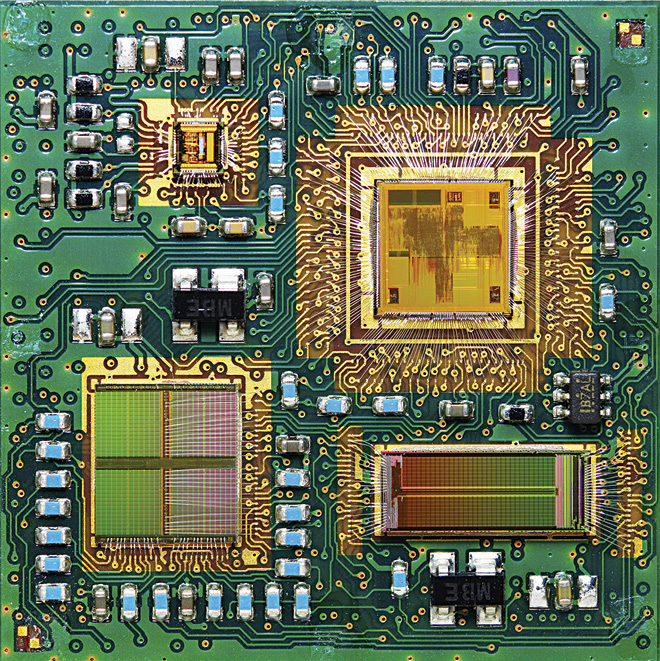

The fact that most big players in IC manufacturing have their signature power reduction technologies itself proves how seriously the industry takes power management issues. eXtreme low power (XLP) by Microchip, fin-shaped field effect transistor (FinFET) by Taiwan Semiconductor Manufacturing Company (TSMC), fully-depleted silicon-on-insulator (FD-SOI) by STMicroelectronics and picoPower by Atmel are some examples.

(Courtesy: http://developer.axis.com)

We also have digitally-enhanced power analogue products in the market that offer a combination of digital configuration and analogue control, providing fast-responding, high-efficiency power conversions with firmware configurations. These also offer high-power-density solutions, excellent accuracy and digital communication interfaces.

Some of the power management components manufacturers and distributors provide support to customers for selecting the right technologies and customisation standard off-the-shelf solutions for the given application(s), while reducing design time and cost.