Often, we struggle to clean electronic gadgets and other gizmos, especially those having small, delicate, inaccessible parts. The proven solution to such a need is an ultrasonic cleaner. In order to understand how an ultrasonic cleaner works, we should look at the techniques behind it and its inner electronics.

Nothing but a bubble

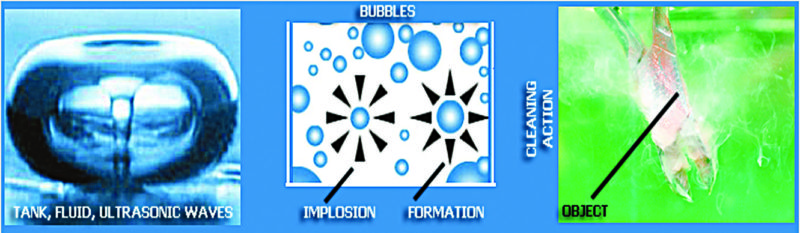

At the heart of ultrasonic cleaning is a bubble. Bubbles are created by ultrasonic sound waves (having frequencies higher than audible sound) as these move through water. This is known as cavitation, which is simply the formation of bubbles (cavity) in water. Since bubbles created through cavitation are just empty spaces, there is nothing to keep these open. As a result, bubbles implode almost as fast as these are created.

In an ultrasonic cleaner, this happens millions of times per second. This constant implosion produces tremendous vacuum energy in the form of heat and pressure that gives enormous cleaning power to ultrasonics. When cavitation happens near a dirty object, vacuum action produced by those millions of bubbles constantly imploding creates a tiny pressure wave that reaches deep into every nook and cranny of even the most delicate items. This tiny pressure wave dislodges and breaks up the dirt and other contaminants and gently lifts it away. The result is very fast and effective cleaning.

The silent scrub

You can use ultrasonic cleaning for fast and perfect removal of contaminants from objects by immersing these in a tank of fluid flooded with ultrasonic waves. Ultrasonic energy enters the fluid within the tank and causes the rapid formation and implosion of minute bubbles. The bubbles rapidly increase in size until these implode against the surface of the object immersed in the tank. The resulting enormous energy release lifts contamination off the surface and innermost recesses of even intricately-shaped parts.

Ultrasonic cleaning is the ultimate solution for cleaning contact lenses, jewellery and metal goods such as dental tools, watches and screws. With the right method, ultrasonic cleaning can thoroughly strip the object of dirt, dust, grime and other contaminants, both on the outer and inner surfaces, without causing any damage to the object.

The cleaning process is non-destructive and produces consistent cleaning results of the highest standard, time after time. Ultrasonic cleaning is an energy-efficient, environmentally-friendly and technically-feasible alternative to cleaning solvents that are ozone-depleting and have other undesirable characteristics. Reduced emissions, biodegradable waste and a safer working environment are among the many benefits of using an ultrasonic cleaner.

Cleaning Machines

Nowadays, in addition to industry-grade equipment, lightweight (portable/desktop) ultrasonic cleaners are also available for day-to-day cleaning of objects. These cleaners come in a range of sizes that have different working frequencies. Desktop models with lower frequency (40kHz -70kHz) waves are good for home and dental equipment. Powerful cleaners capable of making ultrasonic frequencies as high as 200kHz (70kHz -200kHz) are expensive, but worth the investment for precious jewellery and objects with fragile parts, such as watches and contact lenses.

Basic components of an ultrasonic cleaner include an ultrasonic transducer, an ultrasonic generator and a tank filled with aqueous solution. The key component is the transducer that generates the high-frequency mechanical energy. Outer body of the ultrasonic cleaner consists of a stainless steel tank (usually accompanied by a steel mesh basket to keep the object), also known as the ultrasonic tank.

A transducer is usually placed at the bottom or on the sides, or sometimes both when watt density is a concern. It can be welded directly into the tank, or a watertight immersible unit can be placed directly into the aqueous solution. The ultrasonic generator converts a standard electrical frequency of 50Hz – 60Hz into high frequency required for the task, in the ultrasonic range.

A piezoelectric transducer, commonly used in common models, contains piezo-ceramic crystals that change their size and shape when exposed to ultrasonic waves. This causes the sides and bottom of the tank to vibrate and form innumerable microscopic bubbles in the fluid. As these expand and compress alternately, a vacuum cavity builds up within these.

In addition, the crystals’ constant impact against each other produces heat energy. Since cleaning of some objects calls for precise time and temperature control, a timer and heater circuitry is also included in the ultrasonic cleaner. (Heated ultrasonic cleaning improves the cleaning efficiency by removing trapped air in the fluid.)

Besides, auto-follow electronic circuitry in latest ultrasonic generators is designed to maintain the centre frequency when the ultrasonic tank is subjected to varying load conditions. When parts to be cleaned are placed in the tank, or when water level changes, the load on the generator changes. With auto-follow circuitry, the generator matches electrically with the mechanical load, providing optimum output at all times to the ultrasonic tank.

When it comes to the cleaning solution, regular tap water works just fine for a desktop (home-grade) ultrasonic cleaner. Electronic goods and jewellery, however, need a more powerful cleaning agent. Note that, water-soluable special ultrasonic cleaning solution is also available. It conducts ultrasonic waves better than regular water. Some of these ultrasonic cleaning solutions are general-purpose, while others are intended for specific objects.

Inside Electronics

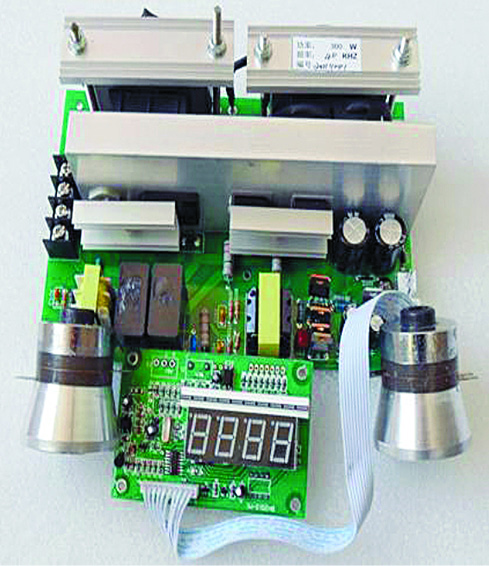

Electronics of an ultrasonic cleaner consists of a power supply, an ultrasonic generator and transducers. Usually, a main printed wired board (PWB) holds all components of the power supply and the ultrasonic generator. A sub-circuit board is used for the microcontroller-based timer/heater commander, and this board also carries user interface keys, indicators, the display panel and so on. Whole electronics of a Chinese ultrasonic cleaner (40kHz/100W) is shown in Fig. 5.

Piezoelectric ultrasonic transducers are made up of several components. The ceramic (usually lead zirconate) crystal is sandwiched between two strips of tin. When sufficient voltage is applied across the strips, it creates a displacement in the crystal, known as piezoelectric effect. In principle, the ultrasonic transducer is effectively a series-resonant LC circuit, where piezo plate electrodes form a capacitor, and the resonating mass acts as an inductance.

The metal horn attached to the transducer focuses the energy into a small area, as demanded by the specific application. The horn vibrates at its own resonant frequency, so resonant frequency of the complete setup (transducer and horn) is a blend of the two. When the transducers are epoxied to a diaphragm on the walls or the bottom of the tank, displacement in the crystal causes a movement of the diaphragm, which, in turn, causes a pressure wave to be transmitted through the aqueous solution in the tank.

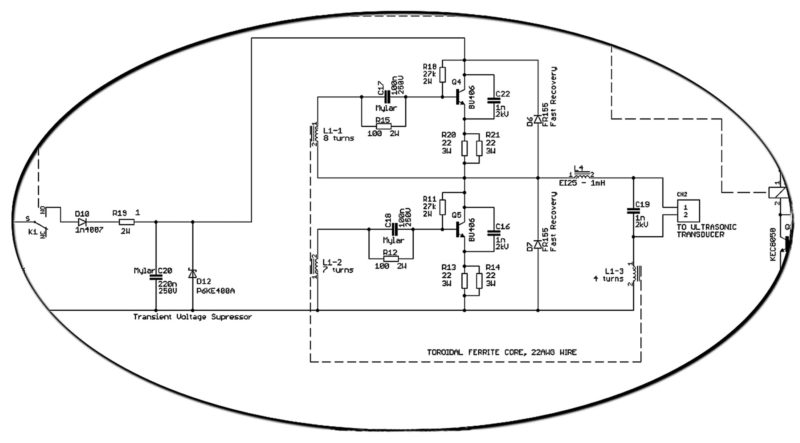

The transponder driver circuit is, in fact, a variation of the famed Royer oscillator—an electronic relaxation oscillator that employs a saturable-core transformer. Fig. 6 shows the partial schematic of an ultrasonic cleaner with a clear view of the transponder driver circuitry.

Ultrasonic cleaning removes a variety of contaminants from parts immersed in aqueous media. Contaminants can be dirt, oil and grease, to name a few. Materials that can be cleaned include metals, glass, ceramics and so on. Ultrasonic cleaning is powerful enough to remove tough contaminants, yet gentle enough not to damage the substrate. It provides excellent penetration and cleaning in the smallest crevices and between tightly spaced parts in a cleaning tank.

Typical applications found in the metal industry are removing chips and cutting oils from cutting and machining operations, removing buffing and polishing compounds prior to plating operations, and cleaning greases and sludge from rebuilt components for automotive and aircraft applications. Fig. 7 shows a typical application example—flux removal from printed circuit board using an ultrasonic cleaner.

Give Care

Efficiency of the core component, the transducer, affects both the cleaning time and efficacy achieved during the cleaning cycle. As the cleaning power of a unit stems from the transducer’s performance, it is good to select a reputed-brand ultrasonic cleaner integrated with reliable transducers.

Besides, there are other variables that need taking into account when cleaning items. Heat, power, frequency, detergent type and time influence the overall cleaning process. Also note that, the main electronic circuitry in most heated tabletop models is susceptible to damage from excess temperatures, so it should be set at optimal levels as recommended by the manufacturer.

Whenever possible, it is best to use a water-based detergent in the ultrasonic cleaning process. Water is an excellent solvent. It is non-toxic, non-flammable and environmental-friendly. Cavitation energy in a water-based solution is more intense than in an organic solvent.

Similarly, temperature of the solution has a profound effect on ultrasonic cleaning potential. Higher temperatures will result in higher cavitation intensity and better cleaning. However, if the temperature approaches the boiling point of the solution (water cavitates most effectively at about 70°C), the liquid will boil in the negative pressure areas of the sound waves, reducing or eliminating cavitation.

What is the source of the ultraso ic transducer/driver/display?

Thank you.

Has anyone encapsulated the transducer? What encapsulate? Heating/transducer contact/resonance issues?

Thank you.