Thinking of how to speed up your assembly lines? These IoT-based soldering irons with

easy-to-use menus, stable temperature, and sleep mode features might help. This article discusses some innovative soldering trends that can elevate assembly to a new level

Soldering is a critical part of the production chain or the assembly line that can completely change the fortune of a manufacturing organization. With the new trends and innovations in the electronics industry, the traditional soldering stations in an assembly line need to be updated.

There are numerous innovations taking place in the arena of soldering. For example, the assembly lines can now be managed by just tracing the performance and precision of the soldering work. Not just that, there are special soldering tips being introduced for hard-to-reach areas in a chip or a system. These innovations, if utilized well, can completely change the pace of production for good.

Many soldering iron manufacturers are now designing their irons with ergonomics in mind. Ergonomic soldering irons are designed to fit comfortably in your hand, reducing the risk of strain or injury. They often feature comfortable grips, adjustable stands, and other accessories that make them easier and safer to use. A shorter grip-to-tip distance allows more control.

Key Factors to Consider When Purchasing Soldering Equipment

Let us have a look at some of the innovations, so you can make an informed decision when purchasing your soldering equipment.

Heat Control

Heat control manages temperature across various components as higher temperatures are needed for soldering larger or thicker components while lower temperatures are needed for more delicate work or for working with heat-sensitive components.

The ‘Quick Heat’ feature in PX-280 soldering iron from Goot reaches a temperature in time comparable to that of middle-class soldering stations. The soldering temperature ranges from 200 to 500°C. It reaches 350°C in just 30 seconds with a standard tip. With a high-power heater and sensor, there is almost no temperature fluctuation during heavy-duty continuous operation.

The WE 1010 soldering iron from Weller Tools offers excellent temperature stability. It features a temperature lock that stabilizes heat levels and prevents them from wavering. The device can operate at between 100 and 450°C. It keeps temperatures at plus or minus six degrees Celsius of the intended temperature.

While most soldering irons start at 100°C, the B-Iron from JBC Tools offers a minimum of 30°C, thereby reducing the risk of damaging components and improving the quality of soldering and desoldering.

Tips

In addition to temperature control of a soldering iron, some other factors can also affect heat transfer and control, such as the size and shape of the tip, the type and thickness of the material being soldered, and the amount of solder being used. Proper heat control is essential for achieving a successful and reliable solder joint.

Companies offer a variety of soldering tips that enable precision while working. These tips vary as per their applications; hoof tips are meant for larger amounts of solder, knife tips to reach into the slotted cavities and edges, chisel tips are multi-purpose solder tips, and conical tips are for precision work. Companies like JBC and Weller offer a broad range of tips to choose from.

If you are buying tips for an existing soldering station, make sure that the tips are built to match and operate with your equipment. Some tips are intended for heavy-duty use while others are intended for light-duty and precision work.

Sleep Feature

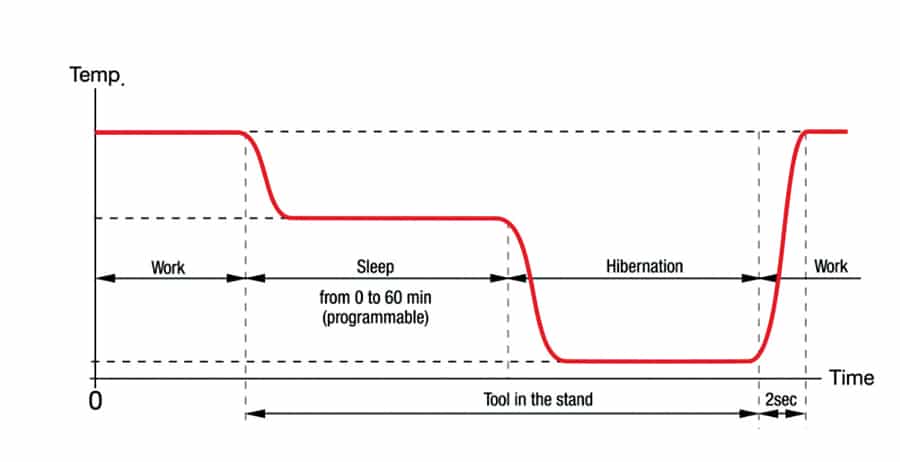

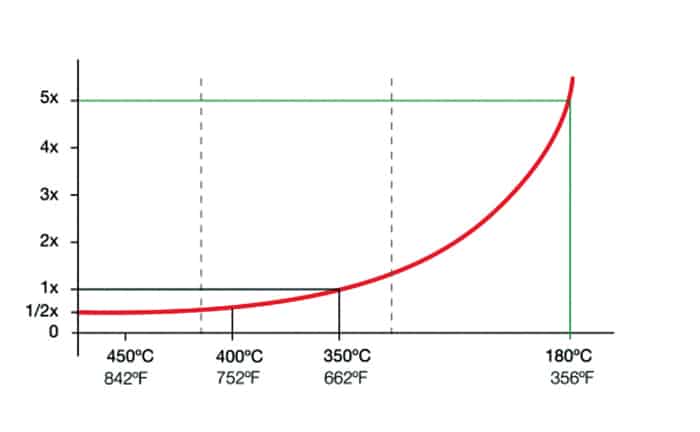

Tip life increases exponentially by using lower temperatures. Using the sleep mode, the average temperature can be further reduced, which can extend a tip’s life five times. The sleep mode automatically lowers the tip temperature below the solder melting point when the tool rests in its stand. It prevents the dissolution of the tip’s iron coating into molten solder.

After a configurable period of tool inactivity in the stand (10 minutes factory default), the tool enters into hibernation mode, which cuts off the power supply and lets the tip reach room temperature, thus preventing oxidation, and saving energy. Some of the products that offer this feature are WE 1010 soldering iron from Weller Tools, JBC’s B-iron, and PX-280 by Goot (Taiyo Electric Ind. Co.).

| Factors Affecting Tip Life |

| Incorrect technique: Too much pressure on the surface to solder can cause tip or plate breakage. Do not use it as a pointed object or a screwdriver. Choosing the biggest tip possible for each application and working at the lowest possible temperature might do the thing. Iron oxide does not wet nor transfer temperature well (dewetting): The higher the temperature, the greater the risk of oxidation. Keep the tips always tinned while not in use and keep them clean. Too much active flux, causes corrosion: IPC recommends ROL, REL, and ORL flux. The internal flux from small Ø solder reels might not be enough. Providing compatible external flux might help. |

Soldering Stations

The soldering station is the other half of the soldering iron. Soldering stations enable working efficiency and productivity in multiple ways. These are generally used to keep the soldering irons between their use.

But there can also be the need to simultaneously use different soldering tips. To enable such a transition, soldering stations are designed to replace the tools needed for changing tips.

JBC’s soldering station comes with a quick cartridge extractor attached to it. Just place the soldering iron into the holder, pull the iron, and insert a new tip. It reduces idle time and increases operator safety.

Weller also offers something similar. Its WE 1010 comes with a plastic knurled nut located on the soldering pencil by hand. The operator can turn the nut to change the tip. This process also increases efficiency and reduces the time for completing a job.

| Cleaning of Soldering Irons |

|

Cleaning soldering irons is an important part of the complete work-rework process as this can affect the quality of tip and the developing device as well. The soldering kit generally comes with a simple sponge that cleanses the iron, but that is not quite efficient.

Shoritsu Electric Industry, or Senpujin, has designed a cyclone type soldering iron cleaner. A vortex-like air flow is generated inside the cleaner and dirt on the soldering iron tip is removed without contact. It also requires minimal maintenance.

|

Soldering stations enable total control over the soldering iron and the working temperature. Some advanced soldering stations also offer calibration options for temperature control and smart systems that can work as a guide as well.

For example, JBC offers a soldering station with an easy-to-use menu, which displays tools preset independently for each tool type and port. The system analyses the soldering process to help the operator select the best tip for work and see the quality of each soldering joint.

Traceability

Soldering stations are being configured to manage production as well. The traceability feature introduced by Kurtz Ersa and JBC monitors works with power and temperature data in real time.

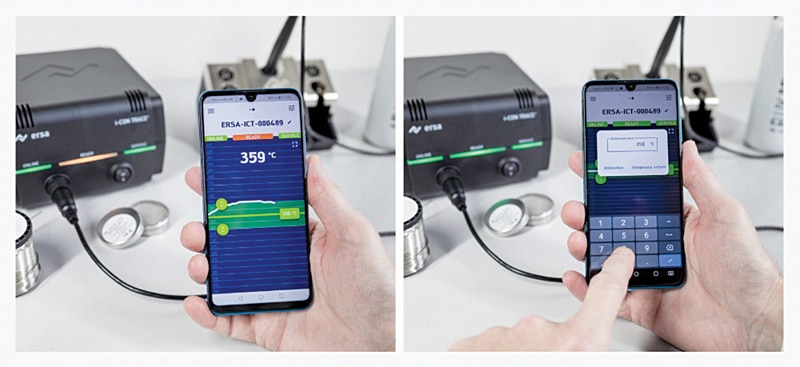

The i-CON TRACE by Kurtz-Ersa is a fully networkable soldering station with an integrated WLAN, Bluetooth, and network card. It can be fully integrated into MES-controlled production processes, making the complete hand-soldering process traceable and documentable.

i-CON TRACE can be connected to a manufacturing execution system (MES) with individually configured settings. This means seamless integration of the i-CON TRACE into networked production processes, which are already controlled by an MES.

Similarly, JBC offers a Web Manager feature, which allows firms to manage JBC soldering stations. This allows you to access station data remotely, using the company network and/or the internet from any device, smartphone, tablet, Android, iPhone/iPad, or computer.

Digital Technology

Incorporating digital technology into the soldering iron is of huge interest as well. Digital soldering irons are becoming increasingly popular due to their accuracy and precision.

Temperature calibration, for example, is one feature embedded in digital irons. The device digitally calibrates the difference between the set temperature and the tip temperature as measured by the tip thermometer.

| Cordless Irons |

| Cordless irons are emerging onto the market as they are extremely portable and great for hard-to-reach spots. But they do not have unlimited run time. And their batteries need to be changed over time. |

These soldering irons come equipped with an LCD screen that displays the temperature and other vital information about the soldering process. The digital temperature control system ensures that the soldering iron maintains a consistent temperature throughout the job.

Digital soldering irons are also equipped with advanced safety features, such as automatic shut-off systems, that prevent the soldering iron from overheating and causing damage.

Finally, soldering irons are becoming more specialized to meet specific industry needs. For example, there are now soldering irons designed specifically for jewelry making, circuit board repair, and automotive work. These specialized soldering irons come with features that are tailored to the specific tasks they are designed for, making them more efficient and effective.

You can also check the quick guide to select the right soldering iron.

This article has been put together by Jay Soni, an electronics enthusiast at EFY