JANUARY 2009: Plasma gasification technology is particularly suitable for disposal of hazardous and radioactive wastes. It is now being seen as an attractive option for disposal of municipal solid wastes as well. This technology has an edge over the other processes involving combustion as it can it can turn solid municipal waste (organic as well as inorganic) into a clean, green, renewable fuel in the form of a synthesis gas (SynGas) with almost no residues that require further disposal.

The major advantages of plasma arc technology are:

1. Compared to combustion/incineration technology, it creates much less atmospheric pollution.

2. In techno-economic terms, oxides of nitrogen and sulphur are not emitted during normal operations because the system works in the absence of oxygen.

3. Toxic materials become encapsulated and are therefore much safer to handle than the toxic ash left by combustion/gasifier processes.

Despite the mentioned advantages, the process is cost-intensive. As per 12th Finance Commission guidelines for grants, plasma arc technology may only be employed for hazardous or bio-medical wastes. For various other well-known conventional waste management techniques, see Box.

[stextbox id=”info” caption=”Other Well-known Waste Management Techniques”]

Managing domestic, industrial and commercial waste has traditionally consisted of collection, followed by disposal. Depending upon the type of waste and the area, a level of processing may follow collection. This processing may be to reduce the hazard of the waste, recover material for recycling, produce energy from the waste or reduce it in volume for more efficient disposal.

The other important waste disposal methods are briefed below. Of these, anaerobic digestion/biomethanation is comparatively a new method.

Landfills. Disposing of waste in a landfill is the most traditional method commonly practised in most countries. Few people want a landfill in their local neighbourhood because of adverse environmental impact.

Incineration. It is the process of destroying waste material by burning it. It involves high temperatures of 870°C to 1200°C (1400°F to 2200°F), to volatilise and combust (in the presence of oxygen). It is recognised as a practical method of disposing of hazardous waste materials (such as biological medical waste). The levels of chemical compounds released into the atmosphere when burning mixed waste, cause environmental pollution.

Anaerobic digestion/biomethanation. In this process, the organic fraction of the waste is segregated and fed into a closed container (biogas digester). In the digester, the segregated waste undergoes biodegradation in the presence of methanogenic bacteria under anaerobic conditions, producing methane-rich biogas and effluent.

The biogas can be used either for cooking/heating applications, or for generating motive power or electricity through dual-fuel or gas engines, low-pressure gas turbines or steam turbines. The sludge from anaerobic digestion, after stabilisation, can be used as a soil conditioner (manure) depending upon its composition, which is determined mainly by the composition of the input waste.

Biomethanation is the most widely used technology all over the world, more so in Europe. The Main Advantage is that it is environment-friendly and reliable. The only disadvantage is that it cannot treat non-biodegradable organic fractions.

[/stextbox]

What is plasma?

Plasma is the fourth state of matter (the other three states being solid, liquid and gas). It is an ionised gas that exists in nature, for example, during lightning. Much of the universe exists in plasma state. The sun, stars and the interstellar matter are plasma manifestations. The gas in the upper parts of the ionosphere (say, above 400 km altitude) is completely ionised. On cosmological scales, plasma is entirely dominating the universe, with safe estimates giving that at least 99 per cent of all matter is in the plasma state.

Plasmas are electrically conductive. These consist of freely moving charged particles, i.e., electrons and ions along with neutrals—all at different temperatures. Plasma densities vary widely from 103 to 1033 charged particles/m3 while the corresponding temperatures vary from 102 Kelvin to 108 Kelvin. For details, you may refer the chart at ‘http://FusEdWeb.llnl.gov/CPEP/’

What a plasma gasification system can do?

It can completely dissociate all organic and inorganic matter into their elemental compounds for recovery and recycling. Plasma can be industrially produced using a plasma torch (Fig. 1). The plasma torch can produce extremely high temperatures that cannot be otherwise created except through nuclear fusion/fission.

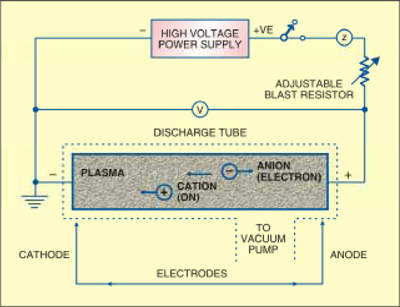

By passing a DC current between the cathode and the anode of the plasma arc torch and simultaneously passing of air in the annular space of the torch, an extremely high-temperature environment is created ranging in temperature from 5000°C to 10,000°C. A simplified circuit of the plasma torch is shown in Fig. 2.

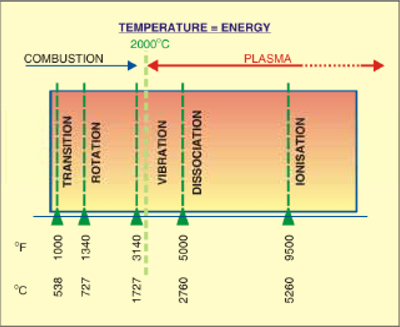

A plasma reactor operates in an oxygen-starved environment and hence there is no combustion. With core temperature running up to 10,000°C, plasma is able to break down toxic compounds within milliseconds, avoiding the formation of secondary combustion products including the polluting flue gas. The molecular dissociation zone starts above 2700°C. Any temperature below this will produce incomplete dissociation. Thus with the temperatures achieved in a PGV system (above 2700°C), all the molecules are totally dissociated. Fig. 3 shows the effect of temperature on the state of matter as the temperature rises to about 10,000°C

General classification and treatment of wastes in plasma gasifier

All wastes may be generally classified into organic or inorganic wastes. Organic wastes are associated with living things, i.e., having biological origin, e.g., flora, fauna, food and living beings. These all have carbon-based compounds.

On the other hand, inorganic wastes are those having non-biological (or geological) origin, e.g. minerals, rock, sea and air. Most inorganic compounds lack carbon, e.g., salt (NaCl) and ammonia (NH3); however, a few, such as carbon dioxide (CO2), do contain it, but it is never attached to hydrogen atoms as in hydrocarbons. Inorganic molecules tend to have a relatively small number of atoms as compared to organic molecules.

The plasma torches that operate at very high temperatures (between 5000ºC and 100,000ºC) can process both inorganic and organic wastes including industrial and nuclear wastes at atmospheric pressure. Transformation of organic and inorganic matter in the plasma reactor results in the following:

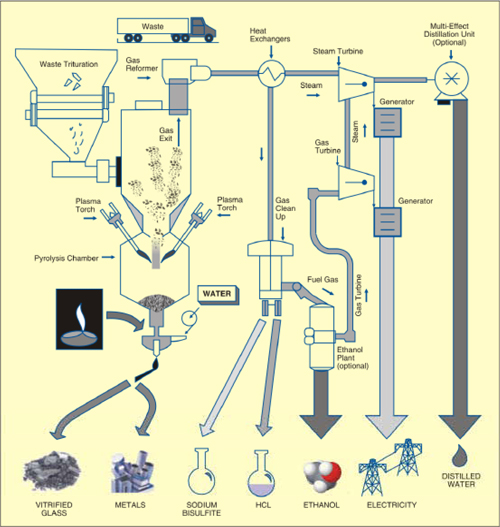

1. The extreme temperatures generated using a plasma torch system (reactor), transform the organic matter into basic gases such as synthetic gas—a mix of hydrogen and carbon monoxide gas. This synthetic gas is almost a green fuel, which is used by advanced gas turbines for the generation of electrical power.

After purification process, SynGas is often cleaner than the natural gas (mixture of hydrocarbon gases). Its heating value depends on the type of feed treated, but typically SynGas has a lower heating value of 10-15 mega-joules per kilogram.

2. The inorganic materials are simultaneously melted into molten slag, which upon cooling becomes a vitrified, inert glass-like material (through magmavication process) that can be used by the construction industry. The homogenous and sulphuric products contained in the feed are transformed respectively to HCl (hydrochloric acid), HF (hydrofluoric acid) and H2S (hydrogen sulphide). Suitable neutralisation techniques for these three products are employed. No ashes are produced in the process.

An artistic view of complete processing of trash (feed) and generation of byproducts using the plasma gasification technology is shown in Fig. 4.

Components of plasma gasification system

The design of plasma gasification plant is not standardised and various companies engaged in their manufacture custom build the facility as per customers’ specifications. However, following are some of the essential parts of any such facility:

Trituration and conveyor section. This section comprises a grinder or crusher for breaking the trash into manageable size for handling by the conveyor, which pushes it to the plasma furnace.

Pyrolysis chamber with plasma torch/torches. It is an air-locked chamber with one or more plasma torches. It allows the garbage in but prevents hot gases from escaping into the atmosphere. The chamber is lined with heat-resistant refractory material. Towards the bottom side of the chamber is drainage system for slag. It also incorporates a water-cooling system. Towards the top of chamber is the exit vent for the gases.

Gas reformer and heat exchanger. The reformer reforms hydrocarbon fuel into a reformate gas such as hydrogenrich syn gas. In the heat exchanger, the hot gases heat water to produce steam, which is then used for running a steam turbine coupled to a generator to produce electricity.

Gas cleanup filter. As the gases produced by pyrolysis mainly comprise carbon monoxide (25 per cent), hydrogen and hydrocarbons (15 per cent), and carbon dioxide and nitrogen (60 per cent), the next step is to ‘clean’ the syngas or producer gas. Thereafter, the gas is burned in internal combustion (IC) engine generator sets or turbines to produce electricity.

Pyrolysis and gasification: similarities and differences

Pyrolysis is thermal degradation of waste in the absence of air to produce char, pyrolysis oil and syngas, e.g. the conversion of wood into charcoal.

Gasification is breakdown of hydrocarbons into a syngas by carefully controlling the amount of oxygen present.

Both pyrolysis and gasification turn wastes into energy-rich fuels by heating the waste under controlled conditions. Whereas incineration fully converts the input waste into energy and ash, these processes deliberately limit the conversion so that combustion does not take place directly. Instead, they convert the waste into valuable intermediates that can be further processed for materials recycling or energy recovery.

Caution. It is rather early to draw conclusions about toxicity effects of the emissions from both these processes, because the true impact of most chemicals and the mixtures of chemicals are still poorly understood.

TO BE CONCLUDED NEXT MONTH

It is a nice presentation.

Thank You for your valuable feedback.