Since their inception in the 1960s, digital multimeters (DMMs) have undergone many changes. With features like auto-ranging, infrared (IR) and surface-temperature measurements integrated into a single device, the DMM is no longer a tool just for measuring circuit parameters. It has developed into a very versatile instrument with extreme safety features incorporated into it.

With demand for portable equipment, hand-held DMM is being used more than its benchtop brother. Certain security ratings and wireless additions have added to the safety of maintenance, repair and operations staff working with high-tension wires. Let us take a look at the availability, development and advances in these handy devices.

There is something in the air

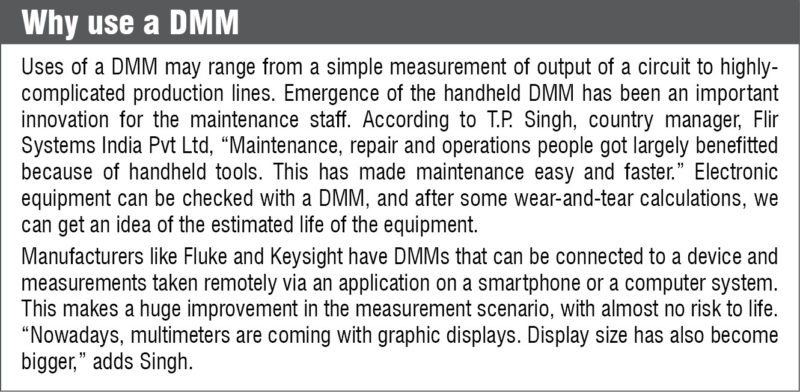

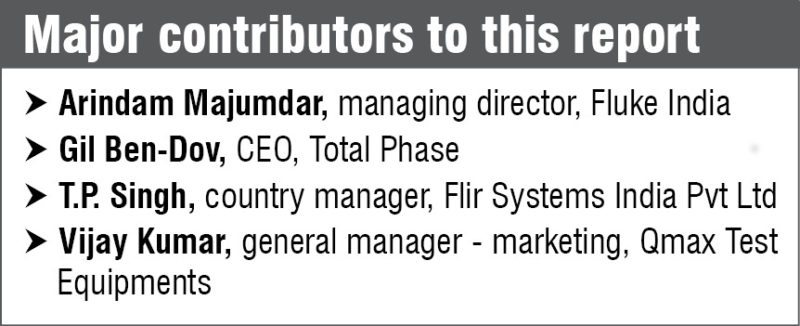

Requirement for highly-accurate and precise results has lead to the emergence of certain added features besides regular measurement that help in fine-tuning the measurements. Arindam Majumdar, managing director, Fluke India, states, “One emerging trend in the global test and measurement (T&M) equipment market is wireless connectivity of T&M equipment.”

With addition of wireless features, we now have smart-DMMs capable of providing measurements to mobile applications. Keysight offers U1177A IR-to-Bluetooth adaptor, which can be connected to their DMM, in order to gain wireless capability. Users seem to have taken a certain liking to such devices. The ability to operate a DMM from afar without any harm to life seems to be the added motivation behind this change.

There has been a rapid increase in the manufacturing of such equipment. Such wireless DMMs employ Bluetooth Low Energy (BLE) in their operation, hence performing operations at the lowest power possible. An example of such wireless capability would be 3000 FC DMM from Fluke. With remote-logging and wireless capability, it can send measurement data to a designated smartphone. True-RMS measurements, 6000-count resolution, manual and automatic ranging provide a very wide set of measurements. Additionally, it provides higher 0.09 per cent basic accuracy, a digital display, up to three secondary measurements from remote modules and a bright white backlight.

Safer measurements

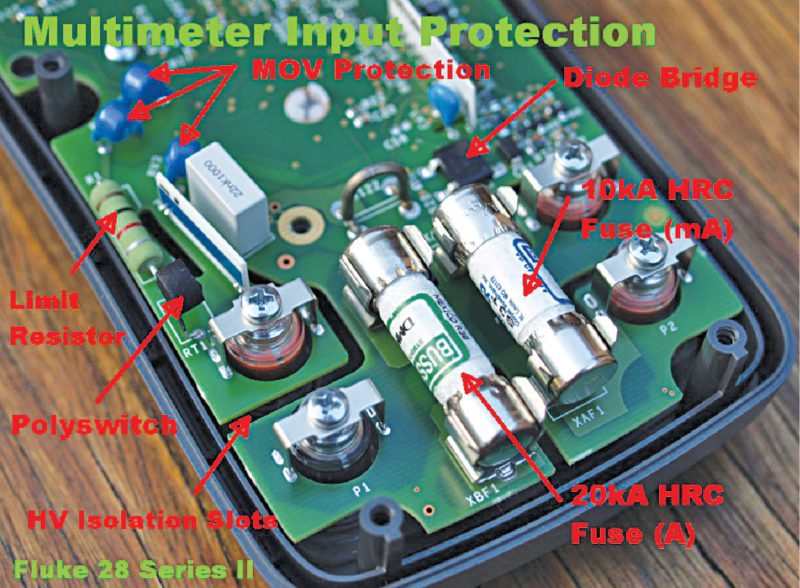

Wireless-enabled test equipment have a safety angle. These let the technician turn off the supply, place the test equipment while wearing insulated personal protective equipment and turn it back on from a safe distance, hence protecting self and reading test parameters on a smartphone or computer system. There are other safety measures to be found in modern DMMs.

Most multimeters include a fuse or two fuses, which prevent damage to the multimeter from a current overload on the highest current range. A common error when operating a multimeter is to set the meter to measure resistance or current and then connect it directly to a low-impedance voltage source. This destroys an unfused DMM, whereas a fused DMM would survive.

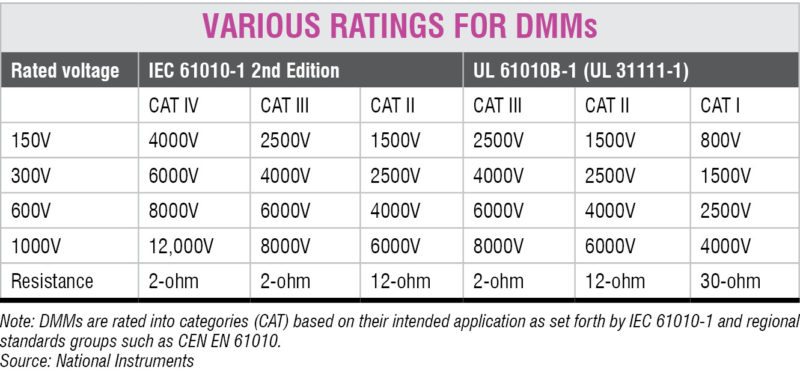

These highly-accurate and easy-to-use equipment can be life saving in certain instances. “All manufacturers are making CAT IV multimeters to take care of safety demand,” says T.P. Singh, country manager, Flir Systems India Pvt Ltd, on security parameters.

Vijay Kumar, general manager – marketing, Qmax Test Equipments, supports the argument with, “True-RMS is important in getting precise readings, whereas CAT ratings are useful in assessing the safety with the equipment.”

Multiple testers in a single equipment

“Today manufacturers offer more measurements in a single instrument. Like in the past, insulation tester and thermometer got integrated into a multimeter,” says Singh. Adding multiple measurements into a single device, so that the technician does not have to go for a separate device each time, has been the motivation behind multimeters.

Low cost with thermometer integration

“Customers with tight budgets now have the choice to upgrade to auto-ranging multimeters that offer the added measurement confidence of true-RMS accuracy,” said Mike Fox, general manager, Extech Instruments, at the launch of EX205T and 210T. These provide measurement capabilities immune to AC waveform distortions and non-contact temperature measurements for added safety on the job. With a built-in IR thermometer, EX210T is optimised with a laser pointer featuring a 4:1 distance to target ratio and a range from -5°F to 446°F (-20°C to 230°C).

Work efficiency: Handheld or benchtop

Another notable trend is the move from benchtop devices to portable equipment. According to Gil Ben-Dov, CEO, Total Phase, “We believe that you cannot always bring the requirement to a lab, so you must have portability.” The equipment is easy to carry, while providing similar measurements.

The market is evolving from bulky and hard-to-move systems to handheld devices. These devices are adopting the latest safety features and are easier to operate under difficult conditions, hence making these versatile. Singh favours benchtop equipment. He adds, “Laboratory applications still need benchtop instruments and I think the future of benchtop instruments will be there.”

Handheld equipment are certainly attractive as these provide portability. Benchtop equipment, however, have the advantage of higher display count, accuracy, precision and no power restrictions, hence optimum results are obtained.

For certain purposes, benchtop equipment will always have an edge over portable equipment. “Handheld equipment have readings in about 4½ units. This is okay for indicative or sometimes even for measurement purposes. For calibration of equipment, we would require benchtop equipment, as these are more precise with a higher display count,” says Kumar.

He adds, “You might use hand-held DMMs for day-to-day usage, but you will certainly require benchtop equipment with certifications like National Accreditation Board for testing and calibration Laboratories (NABL) for calibration”.

DMM7510 digit graphical sampling multimeter from Keithley Instruments is a high-accuracy multimeter with a digitiser for waveform capture and a capacitive touchscreen interface. With resolution levels of up to 7½ digits auto-calibration, it offers signal sampling with 1MS/sec, 18-bit digitiser.

DMM7510 digit graphical sampling multimeter from Keithley Instruments is a high-accuracy multimeter with a digitiser for waveform capture and a capacitive touchscreen interface. With resolution levels of up to 7½ digits auto-calibration, it offers signal sampling with 1MS/sec, 18-bit digitiser.

What influences multimeter design

Among the factors taken into consideration, Majumdar points out the regulations on the quality of power in the industry and awareness and implementation of electrical safety standards. According to him, “Several industries are now achieving compliance to their industry-specific norms. This, in turn, calls for the need of more accurate, precise and robust T&M technology.”

Development of these DMMs requires certain finesse. Since wireless equipment is fundamentally transmitting power in the form of signals, these require a consistent power source. Manufacturers like Qmax have the option of universal serial bus-powered devices as well, which reduce battery constraint.

Designing also depends highly on requirements, as an engineer would like to utilise as many features as possible. “The most important factor is the customer use case. That will govern the need for supported power levels, clock rates, decoding and so on,” says Ben-Dov on the development of DMMs.

DMM: Market and you

“Over the years, T&M equipment has grown in significance, reflecting the critical role it plays in any industry, right from R&D to production and services. Some of the major market drivers include the increasing demand for electronic products and the rising need for T&M equipment for use in semiconductor devices,” according to Majumdar.

The need to deliver safe and highly-accurate electronic equipment has lead to an increase in employing DMMs during the testing and design process. Singh adds, “CAT ratings, IP ratings, stability and repeatability of readings are important things to decide on a multimeter.”

Kumar agrees, “Weighing the pros and cons and considering the use cases are important for proper selection.”

What to look forward to

Better precision and support for different integrated protocol/power measurements, according to Ben-Dov, are the future expectations from multimeter devices. “More products will get integrated in the multimeter to reduce the overall cost, and this also allows a technician to carry fewer tools,” adds Singh.

Major changes in a multimeter are not the observed pattern. These evolve slowly over the years, and with involvement of wireless capabilities, changes in the near future seem to be confined to the power management system of the device.

Handheld devices generally have a long battery life of about 500 hours in continued usage of AA batteries, making power consumption cost-effective.

Testing of equipment will always be a significant requirement and hence safety of testers will be a responsibility. This is sure to give a boost to the handheld device sector with wireless capabilities.

Saurabh Durgapal is working as technology journalist at EFY