Complying to standards calls for a structured approach. In every phase of the product development, impact of standard compliance has to be assessed and actions have to be taken. This is very important. If a list of the items to be checked is prepared, it will run into a book. Here is some guidance on the subject

When products are designed there are three aspects that are critical: The product’s usability, performance, and compliance to standards. All three aspects are focused on the users to ensure they get the best when they buy a product.

For example, let us say the product is a washing machine. The user interface of the product should be easy to use, intuitive, and consistent, so that no training is needed for operating it. Second aspect is performance, where the washing machine has to meet all the product specifications and claims made by the manufacturer. Third is the compliance to standards.

Standards are drafted to address three aspects:

- Safety of the user (both electrical and mechanical)

- Use of environmentally safe manufacturing processes

- Safe electrical emission and susceptibility

Complying to the standards is mandatory and exporting to different countries depends on the standards laid. Typically, standards are defined by international agencies like FDA, FAA, IEEE, IEC, etc. In India we have Bureau of Indian Standards (BIS) (earlier was known as Indian Standards Institute) which has standards for products made and used in India. Almost all the countries have made compliance to standards mandatory.

For complex products like aircrafts and military systems, most countries tend to follow FAA (Federal Aviation Administration) and FDA (Food and Drug Administration) standards. Similarly, standards like Electrical Radiation Emission and Susceptibility, FCC (Federal Communication Commission) of the USA, or CE (Conformité Européenne) for European Union are used across countries as these standards have been well drafted and have stood the test of time. With the increased integration into global economy, India is also now mandating standards for use in India.

Most designers tend to assume that compliance to standards is a separate step and can be done once the design is complete. However, compliance to standards needs attention from the design phase. In fact, one of the design parameters should be the standards to which the product has to comply. For example, if the product has to meet FCC Class B emission level, it is better to have metallic enclosure rather than a plastic enclosure—if the design allows. So, designers need to understand the standards to which the product should comply and ensure the design goals meet that.

Why this is critical

Why this is critical

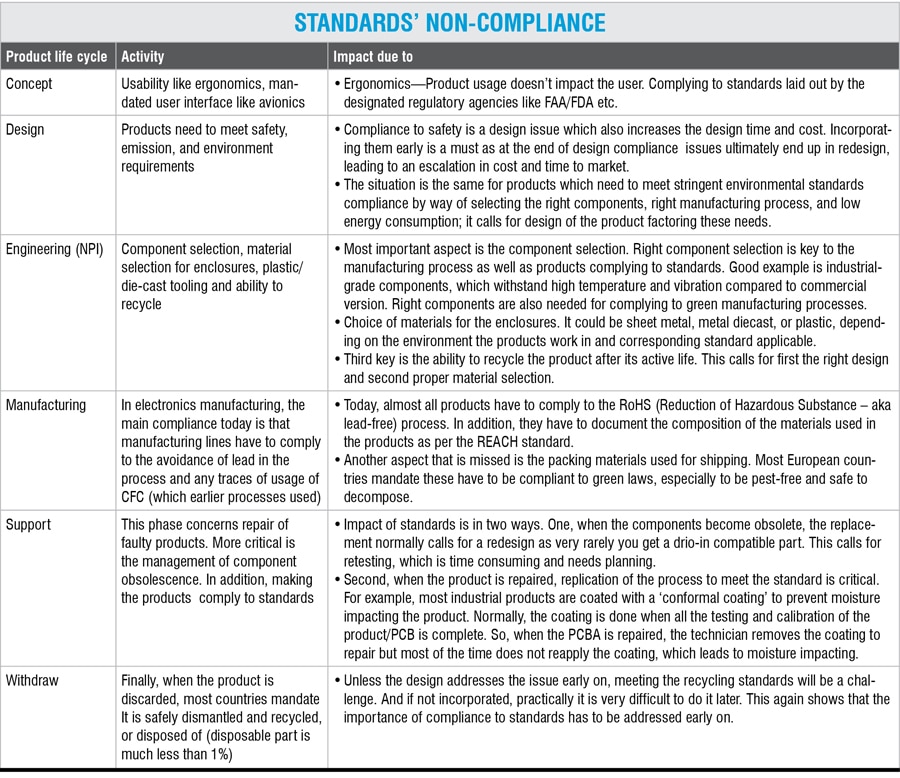

First and foremost reason for compliance is the impact on business. Products that do not meet the standards cannot be sold in the market. Second, assuming there are markets where the standards compliance is lax and the products can be sold, risk of safety issues and the litigation due to that can far outweigh the compliance to standards. Complying to standards must start from design stage and not after the design is complete. Let us see which activities get impacted due to standards’ non-compliance in the Table.

Some examples

Just to show the importance, two instances of compliance to standards not being met are briefly described below along with the mess they created.

First, we were designing an advanced antenna that could adjust its lobe width by operating a motor mechanism. We completed the testing and certification. However, when this antenna was installed in a European nation known for low temperature, we noticed two things. One, the motor froze, and second, the processor failed to start. In both cases what we found later was that the components we had used for testing and those used for manufacturing (even though the datasheet said they were equivalent) were different, leading to the failure. While we could sort the motor issue, we found that most crystals don’t start at -15°C, so we ended up preheating the component used in the design to ensure there were no issues.

Second was a networking product, which was packed in small wooden crates to be shipped to Europe. When the contents landed in European airport the authorities sent the material back due to pests and decay in the wood used. We had to import the crating wood for packaging! This taught us a lesson that even a small miss can cost lots of money and time.

What need to be factored

There are three critical things that need to be factored in when designing products for compliance to standards:

- Know the country the product is supposed to be sold in and get to know the compliance laws and standards well. If the product is being designed in one country and exported to another, the best way to manage is to use global certification agencies like TUV to get the certification as they have the experience and knowledge to address global standards.

- Spend time in selecting components and their equivalents. Above all, even if the product has custom parts made by suppliers, the responsibility of those parts meeting the standards is always yours. Never leave it to the suppliers as they invariably don’t appreciate the need for complying to standards. (An entire lot of advanced remote access server we shipped to the US was sent back as the welded portions rusted while they were in US airport for a week.)

- It is advisable to have a full-time engineer to address the issues if the products are being targeted for global markets. This helps in keeping the compliances issues to the minimum.

Points to keep in mind

Complying to standards calls for a structured approach. In every phase of the product development, impact of standard compliance has to be assessed and actions have to be taken. This is very important. If a list of the items to be checked is prepared, it will run into a book. For a reliable and very useful book on the subject, check https://emcfastpass.com/cert-ebook. It is a good book for MSMEs and startups to understand global standard compliance and how to deal with it. But remember, it addresses all the electrical standards. Designers have to understand the standards for other certifications as well, especially the environmental ones.

S.A. Srinivasa Moorthy is Director Engineering Design, D4X Technologies Pvt Ltd