Researchers from Pittsburgh have developed a novel approach that could assist in speeding up the process of creating ever more optimized batteries

Since there is a huge demand for handheld devices and electric vehicles this increased the demand for batteries that last longer and charge more quickly. Therefore, a team of researchers at Carnegie Mellon University has invented an autonomous optimization approach that consists of a unique type of robot which is integrated with an AI learning system to create more useful non-aqueous liquid electrolytes. They implemented automation techniques to speed up the process.

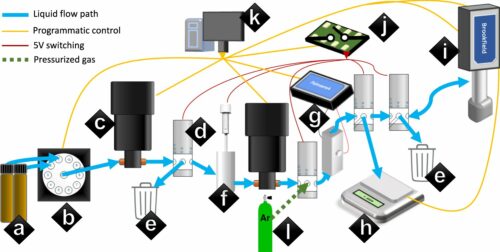

The most essential part of battery design is the creation of a non-aqueous lithium-ion battery electrolyte that works better than those that have been introduced before. Researchers try to find ways to optimize ion conductivity. The researchers invented a robot called Clio that received the ingredients used to make an electrolyte and then applied a set of instructions to make some samples. Further, the data from Clio and from sensors in an electrolyte that is generated by the robot was forwarded to a computer running deep learning AI application (called Dragonfly). Dragonfly then suggested the possible improvements which is accepted by Clio and use to make a new sample.

This process continued multiple times with the electrolyte slowly improving. After a designated time given by researchers is completed the mechanical pair stops operating enabling the researchers to test the products that have been produced. After experimenting the researchers were of the view that their paired system worked as hoped. They analyzed gradual improvements in the electrolyte sample. The best was found to be 13% better than top-performing batteries now on the market.

The researchers aim to refine their system and allow for testing more objectives and perhaps to make it run faster.

Click here for the Published Research Paper