As India strides towards semiconductor prowess, it invites us to ponder: Can this journey redefine global innovation and economic landscapes?

India, traditionally known for its prowess in software services, is now ambitiously moving towards becoming a significant player in the global semiconductor industry. This industry, which is expected to reach a market size of over $600 billion globally by 2026, represents a golden opportunity for India to diversify and elevate its role in the high-tech sector

Semiconductor ambition of India

India’s foray into the semiconductor industry is timely and strategically imperative. In an era where semiconductors are the backbone of virtually all modern technologies—from smartphones, wireless communication, and electric vehicles to AI—the demand for these components is surging globally, making nations more dependent on them. As the world increasingly contends with supply chain disruptions and geopolitical tensions impacting semiconductor production and distribution, India’s entry into this sector could bolster its technological sovereignty and position it as a crucial player in the global supply chain.

Moreover, India’s established strengths in the software sector provide a robust foundation for growth in the semiconductor domain, including the vast pool of engineering talent that accelerates its journey from being a consumer to a creator of semiconductor technology. This transition from software to hardware and services to manufacturing could mark a significant turning point in India’s technological and economic trajectory.

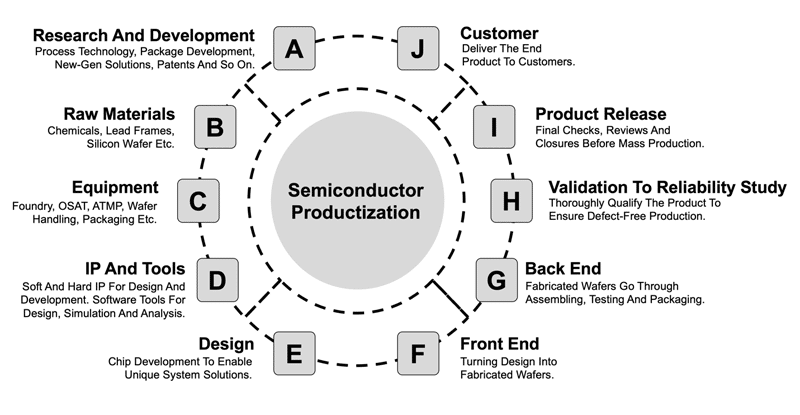

However, a critical aspect India should address before becoming a semiconductor product nation is semiconductor productisation. India has been home to top semiconductor design centres, including startups catering well to semiconductor product development’s design aspect. However, building a semiconductor product involves multiple steps. Ultimately, it entails transforming any silicon idea into a manufacturable product, which includes several critical stages of development to ensure the design is defect-free when mass-produced. In the long run, a nation that can complete all these steps for 100% of the productisation process in-country will lead to semiconductor technological advancement.

What is semiconductor productisation

Semiconductor productisation is critical in the silicon technology value chain because it transforms theoretical and technical capabilities into tangible semiconductor products. This process requires synergy between engineering, manufacturing, marketing, supply chain management, and more. The ultimate goal of productisation is to create semiconductor products that are not only technically proficient but also commercially viable and responsive to market demands. This process encompasses several stages, including:

- Silicon design. Crafting the chip’s architecture, balancing performance, power, and area for targeted applications

- Samples. Creating initial chip prototypes for testing design theories and functionalities using the defined fabrication, assembly, and testing flow plan

- Equipment and hardware. Procuring all the equipment and hardware needed to validate the product, including fabricated (SMT) hardware from scratch

- Silicon bring-up. Initial testing of silicon prototypes to debug and optimise designs

- Characterisation. Detailed analysis of chip performance under varied process, temperature, voltage, and current profiles

- Validation. Rigorous specification-based testing to ensure the chip meets all specified functional requirements

- Qualification/reliability. Testing for reliability under different stress conditions and lifespans

- Compliance. Ensuring the chip adheres to industry standards and regulatory requirements

- Production release. Finalising design and specifications for manufacturing readiness, and ensuring proper fabrication, assembly, and testing flow is in place

- Mass production. Scaling up manufacturing for large-volume, cost-effective chip production

- Distribution. Efficiently distributing chips via seamless logistics flow

- Support. Ensuring mass-produced chips receive proper support if customers face any issues

For several reasons, establishing a complete semiconductor productisation chain within India is pivotal for economic development. It will foster self-reliance by reducing semiconductor imports (including post-tape out services), which encompasses not only fabrication, assembly, and testing but also providing all the technical support needed to complete the above-mentioned steps.

In summary, the development of a semiconductor productisation chain in India is a multi-faceted catalyst for the country’s economic growth, enhancing technological self-reliance, stimulating job creation (as many students still focus on traditional chip designing courses, while numerous career options exist), securing national interests, and positioning India as a leader in a globally crucial industry by completing the entire process in-country, from idea to design to validation to debugging to support to delivery.

How long before India becomes a semiconductor product nation

The timeline for when India will become a semiconductor product nation depends on a multitude of factors, including government policies, industry investments, global market dynamics, technological advancements, university curriculum, awareness among students/professionals, and the development of the necessary end-to-end productisation ecosystem.

However, here is an overview of how India’s semiconductor ecosystem will develop over the following decades, thus leading to 100% semiconductor productisation:

1. Short-term (next 1-3 years)

- India will focus on laying the groundwork for its semiconductor industry, including policy development and investment attraction (already underway).

- Establishing R&D facilities and initiating educational and training programmes, both of which are being actively pursued.

- Initiating partnerships with global semiconductor leaders for technology transfer and setting up assembly and testing units, an area already seeing significant action.

Short-term (next 1-3 years)

- India could establish more advanced semiconductor manufacturing facilities, including fabs, though initially focusing on less advanced chip technologies due to high costs and complexity.

- Focus on scaling production, improving supply chain logistics, and increasing domestic and international market penetration.

- Heavy emphasis on educating students about the ‘productisation of semiconductor ideas’ and its numerous career options, alongside establishing the support ecosystem (semiconductor equipment, raw material, etc).

3. Long-term (10+ years)

- India will become a fully-fledged semiconductor product nation, competitive globally with advanced technology offerings and, likely, a long-term goal spanning over a decade.

- This phase would involve India’s robust manufacturing base, leading semiconductor R&D, design, testing, reliability labs, compliance processes, equipment vendors, and excellent infrastructure, all of which will directly feed into the semiconductor innovation cycle.

In conclusion, while the groundwork for semiconductor productisation can be laid within the next few years, achieving the status of a semiconductor product nation is likely a long-term goal that could take a decade or more. This journey will require sustained efforts, significant investments, strategic domestic workforce development, and numerous international collaborations. It is also crucial to raise awareness in both industry and academia that semiconductors entail more than just chip design; they involve a detailed productisation process.