Today there are almost 20 different technologies that revolve around touch panels. And there are millions of end products that use touch panels for navigation. We have come a long way in technology but how do these touch panels actually work? This aspect plays an important role in selection of such touchscreen panels.

This buyer’s guide is intended to provide an overview of the present state of touchscreen panel technology and its selection criteria to allow selection of the most appropriate touch technology for the intended application.

Selecting the right touchscreen is critical to the product’s success

A touchscreen is a human-machine interface. It is activated by the user by touching, with a stylus or single- or multi-finger touch, the selected area on the display that indicates the desired function. The touchscreen or frame contains an independent x-y coordinate system that is calibrated to the display matrix. The touch point is determined by the embedded computer by the x-y coordinates of the touch point. You, as a user, without using a mouse or keyboard, can interact directly with the information displayed on the touchscreen.

Touch input can provide instant audio and/or visual feedback to you to confirm your choice. Touchscreens are common in devices such as smartphones, game consoles, personal computers, touchscreen TVs, iPads and electronic voting machines, among others. These are widely used in applications such as public information kiosks, industrial and process control, military displays and interactive video systems.

The touchscreen sensor and firmware for the host computer have been made available by a wide array of after-market system integrators, and not by display or chip manufacturers. Display manufacturers and chip manufacturers worldwide have accepted the trend toward acceptance of touchscreens as a highly-desirable user interface component and have begun to integrate touchscreens into the fundamental design of their products.

Ideally, a touchscreen would have the following characteristics:

• As it is layered on top of the display, it should not degrade the display image.

• Its resolution should be equal to that of the video display.

• Activation is independent of size of stylus, conducting or non-conducting nature of styli and touch of gloved or non-gloved finger.

• It is capable of providing positive, tactile feedback to the operator.

• Architecture should be modular and capable of integration with other input devices and networks.

• Due consideration has been given to the human perspective by considering aspects such as ergonomics, cognitive psychology and human physiology.

• It requires precise selection of targets to avoid accidental selection of adjacent targets.

• It is impervious to adverse environmental conditions of dust, grease, moisture, pressure, vibrations, chemical or oil vapours.

However, none of the touchscreens currently available have all of above-mentioned characteristics. Accordingly, selection of any touchscreen panel technology is a compromise that will depend on the particular application and environment. Nowadays, the touchscreen interface is progressively becoming a standard requirement in today’s electronic products.

The technology within the touch panels

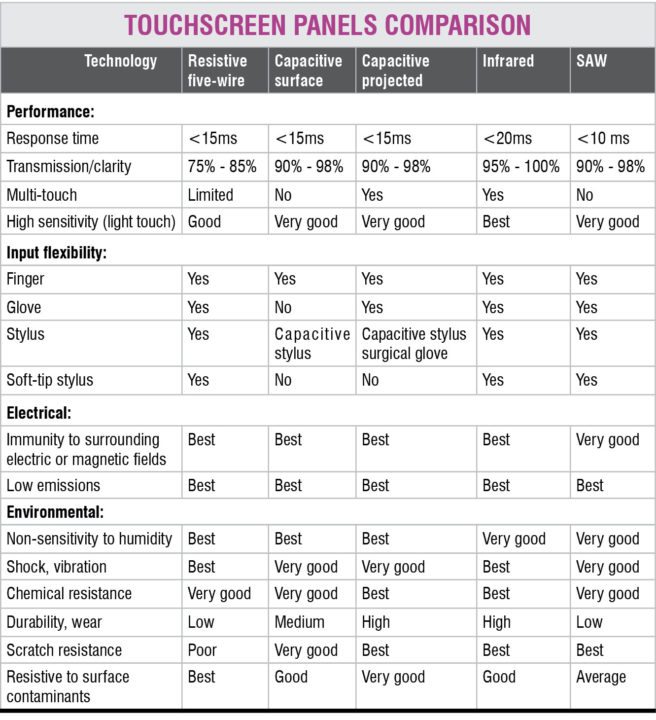

There are a variety of touchscreen technologies with different methods of sensing touch: resistive, capacitive, projected capacitive, scanning infrared (IR) and surface acoustic wave (SAW). Selection of the proper touch technology for a specific application requires evaluation of each type. All touchscreens are composite units comprising a touchscreen overlay and an information-processing controller.

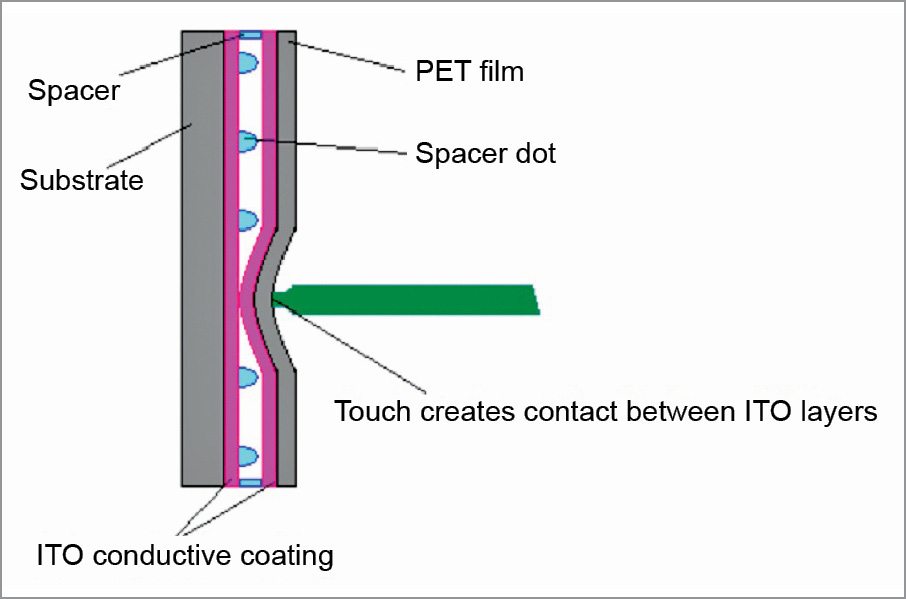

Resistive technology. Five-wire resistive touchscreen is the most widely-used touch technology today. A resistive touchscreen panel is basically composed of a glass panel covered with thin conductive and resistive metallic layers, separated by a thin space. So when you touch the screen, two layers touch at that point. Change in the electrical field is detected by the computer and touch point is calculated. Resistive touchscreens are generally the most affordable, but offer about 70 per cent to 85 per cent image clarity.

The screen can be activated with virtually anything rigid (finger, stylus, gloved hand, pen, etc), and the touch has tactile feel. The screen is resistant to surface contaminants and liquids (dust, oil, grease, moisture).

Major benefits of resistive touch technology are its low cost and low power consumption. There are three types of resistive touch panels available, namely, four-wire, five-wire and eight-wire.

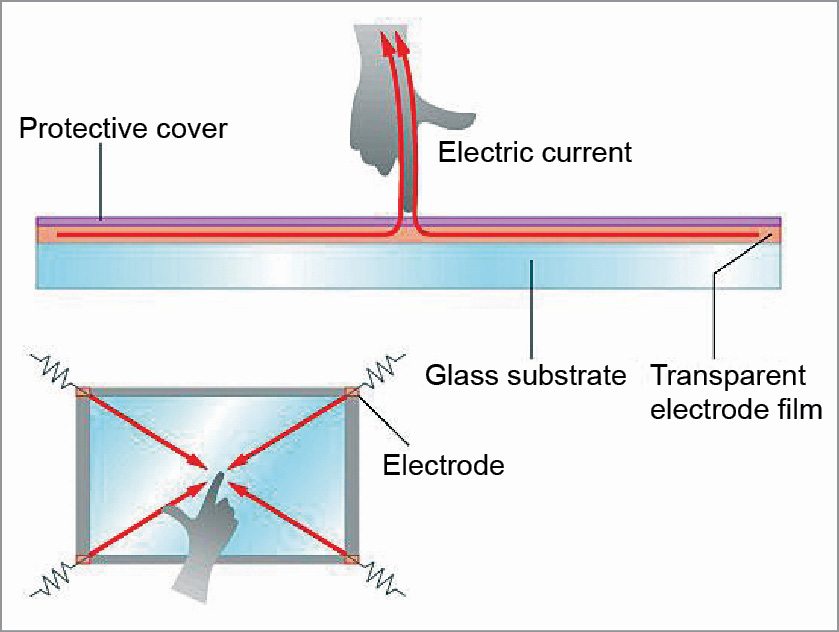

Surface-capacitive technology. A surface-capacitive touch panel works by measuring current. Here, a protective cover is placed over the transparent electrode film on top of the glass substrate. Voltage is applied to all corners, and any contact with the surface disrupts the current. Hence, the touch point is determined by the controller. It is mostly used in the gaming industry. Also, light transmission averages at 80 per cent or above.

This technology offers better image clarity, excellent high resistance to scratching of screen and surface contaminants and liquids (dust, oil, grease, water droplets). A capacitive touchscreen can be operated by the touch of human skin or a stylus holding an electrical charge.

The screens are susceptible to EMI/RFI from the display and environment; higher level of interference can demand more performance from the controller in identifying and rejecting noise that mimics touchscreen activation. These are moderately durable and have limited resolution.

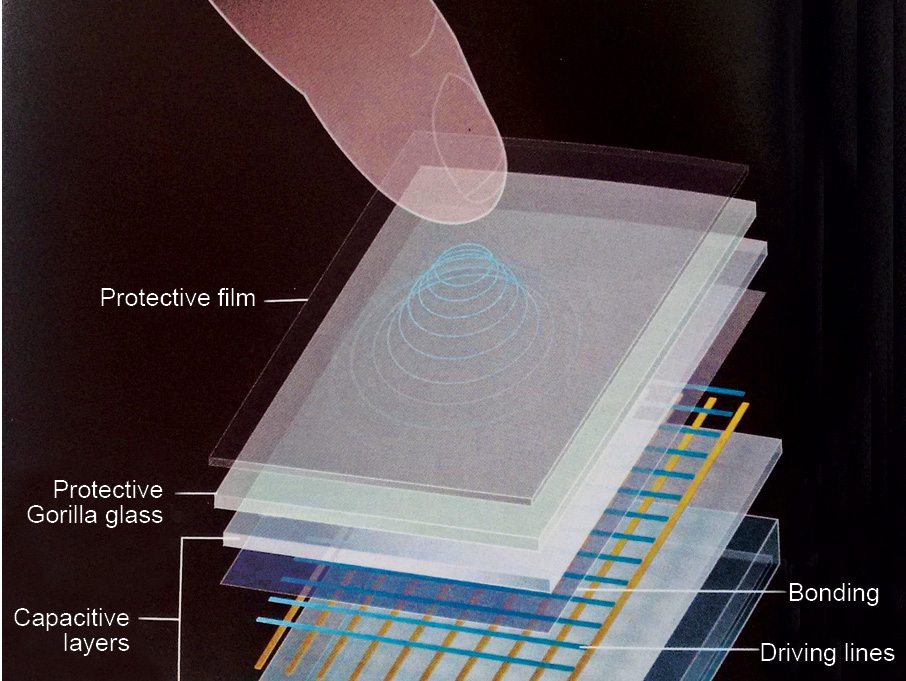

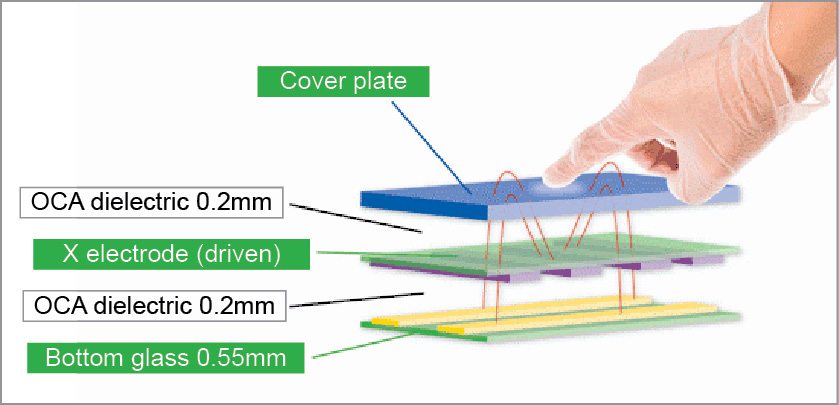

Projected capacitance technology. Projected capacitive technology is the new powerhouse in the market. This technology is basically used within iPhones and iPads. In this technology, the electronic field is projected through the top of the glass, so energy creates an electrostatic field. So whenever there is change on the top of the surface, change in electrodes is detected, which further calculates the touch point.

It is capable of dealing with two to ten multi-touch points simultaneously depending on the controller being used. Lighting is excellent with a light transmission of 80 per cent or more. But cost is higher as opposed to other technologies.

Also, when you are wearing gloves, it is likely that the controller will not be able to register a touch point.

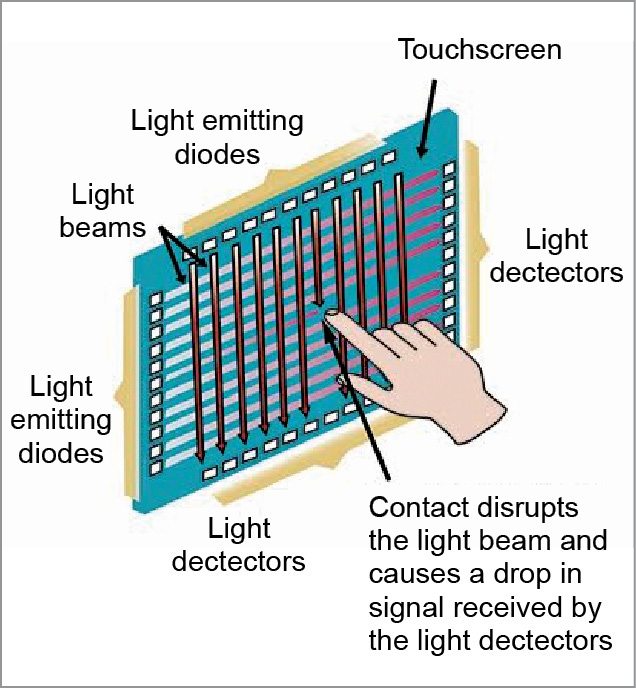

IR grid technology. Another type of mostly used touch panels are the IR touch panels (ITPs). IR technology consists of IR LEDs and light sensors that are placed on the perimeter of the bezel. LEDs transmit beams of light that run side by side to the assigned light sensor and create a light grid. If anything disrupts the light or reduces it, a touch point is registered by the controller.

Performance is sensitive to water, snow, rain and ambient light interference. The screen could malfunction due to build up of dust, oil or grease. Cost is relatively high as compared to other touch technologies.

SAW touchscreen. A SAW is a structure-borne sound wave that spreads across a surface in a planar manner, that is, in two dimensions. The receiving transducer locates the touch point and sends this data to the controller.

SAW touchscreens have excellent image clarity, so can display high-detail graphics. These can be activated by a finger, gloved hand or soft-tip stylus.

However, SAW panels are the most expensive of the three liquids, and any contact with something hard like a pen or finger nail can cause a false trigger. Solid contaminants on the screen can create non-touch areas, until removed.

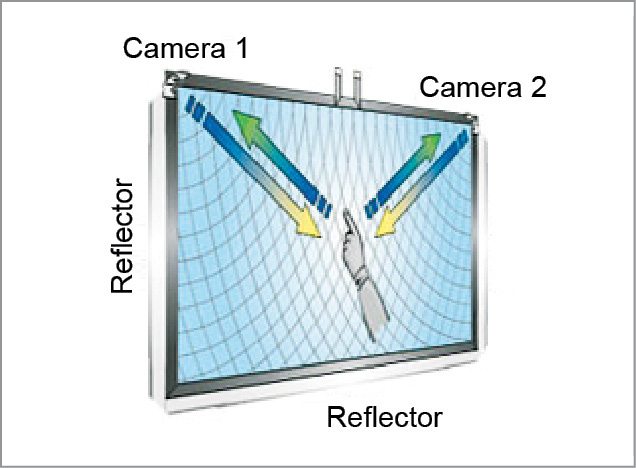

Optical touchscreens. This is a relatively-modern development in touchscreen technology, which uses two line-scanning cameras located at the corners of the screen. IR backlights are placed in the camera’s field-of-view on the other side of the screen.

This technology is growing in popularity due to its scalability, versatility and affordability, especially for bigger units. It permits 100 per cent light transmission and requires only one calibration.

Near-field imaging touchscreens. This is one of the newest technologies and consists of two touchscreens. When the finger, glove or any other conductive stylus comes into contact with the sensor, electrostatic field is disturbed. It is an extremely-durable screen that is suited for use in industrial control systems and other harsh environments.

Factors to consider for buying touchscreen panels

Selection of a touchscreen panel is basically determined by the application and expected users. A panel for a classroom (teacher and students) will have different qualitative requirements when compared with that of a touchscreen controller panel for an industrial setup. In these two setups, size, response time and environment cost will have bearing on the selection of the touchscreen.

Important performance specifications to be considered when buying touchscreen displays include:

Touch type. Touchscreens discussed above have distinct advantages and disadvantages. Selection is therefore a compromise, by adjusting pluses against minuses. Projected capacitive type is ideal for harsh, industrial and outdoor applications. IR type will not fit the bill for such applications. If clarity of a picture is important, then IR will be a preferable option, higher cost notwithstanding.

Screen size. Touchscreens are available in small, medium and large sizes. Touchscreen monitors are usually 8.9cm to 1.3m (3.5-inch to 52-inch) in size. Most common sizes are 38.1cm to 48.2cm (15-inch to 19-inch) and 81.2cm to 1.1m (32-inch to 42-inch) for large control rooms. Large displays up to 2.5m (100-inch) are also available. Aspect ratio (4:3 or 16:9) should also be considered.

Accuracy of touch. This is the ability to provide reliable touch performance in devices when the touch sensor is subjected to large amounts of noise from sources such as displays and chargers. You must be able to accurately select targets on touchscreens and avoid accidental selection of adjacent targets.

Touchscreen resolution. It refers to resolution or the number of touch-active points on the touchscreen. It affects the level of pointing precision and selection errors. Therefore a higher-resolution screen provides additional touch points, allowing greater pointing.

Another resolution (pixel density) to be considered is that of the display, which can be HD, full-HD and so on.

Response time. The shorter the time between a touch and the response, the better you would feel about the touch system. It is specified in milliseconds (ms). Latency is typically 75ms to 100ms. Studies have shown that humans need less than 10ms for comfort. SAW touchscreens have the shortest response time of around 10ms, whereas IR has a higher response time of around 20ms.

Transmission/clarity. Touchscreens are normally on top of the display, so there is loss of light and affect on clarity of the image. But IR touchscreens have no overlay, therefore transmission is 95 per cent to 100 per cent, and clarity is the best. Resistive type has the lowest rating for this attribute.

Life expectancy. Due to continuous use of the screen, degradation in performance is expected. Life of IR type is around five years, whereas capacitive type has a short life of around two years only.

Resistance to scratch, chemical, dust and grease. The top-most layer of the screen must be tough enough to resist scratches. The assembly must have proper sealing to prevent ingress of water and chemicals.

Ergonomics. The design of touchscreen interfaces must reflect on cognitive psychology and humans. This deals with placement of touch points, their size, sequence, colour combination and overall appearance.

Environment. Selection of a touchscreen panel is also based on its deployment. If it is in open and harsh conditions, then selection will be based on the type that can withstand dust, temperature, moisture, etc.

Nidhi Kathuria is a senior application engineer at EFY Labs, New Delhi