Magnetostrictive linear position sensor: Magnetostriction is a property of the ferromagnetic material (such as iron, nickel and cobalt) to change their size and shape when placed in a magnetic field. The sensors working on this principle of ferromagnetic material to measure the distance between a position magnet and the end of the sensing rod towards the electronic housing are called as Magnetostrictive linear position sensors. In this, the position sensor does not touch the sensing rod so, the parts do not wear out.

Application

These sensors become an essential component in the handicapped lift for van or bus apart from sensing the cylinder position in pneumatic cylinders, sensing position in material handling equipments, for detecting the traffic light burnouts and other such industrial applications.

Proximity and Presence

Proximity sensor is a sensor that can detect the presence of nearby objects without any physical contact. These are available in models that use high-frequency oscillation to detect ferrous and non-ferrous metallic objects and in capacitive models to detect non-metal objects.

These convert the information on the movement or the presence of an object into an electrical signal. These sensors do not have any direct contact with the object to be detected so, there are least chances of wear and tear of the device. These can be divided into three categories based on the principle of operation- Inductive sensors, Capacitive sensors, Photoelectric sensors and Magnetic Field sensors.

Inductive Sensors: These are used to detect metallic objects without any contact. These are based on the operating principle of a coil and an oscillator, which creates an electromagnetic field in a closed surrounding. In this scenario, the presence of any metallic object in the operating area causes dampening of the oscillation amplitude. The threshold circuit identifies the rise and fall of the oscillation and changes the output of the sensor. They have long operation life and are extremely robust.

Application

The inductive sensors are used in metal detectors to detect metallic objects without any physical contact. They are also used in car washes and in industrial applications where dirt is prevalent.

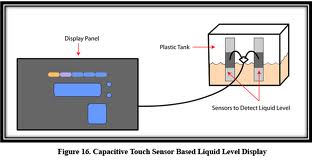

Capacitive Sensors: These proximity sensors are used to detect both metallic and non-metallic objects. The principle on which it works is the variation of capacitance between the sensor and the object that is being detected. An electronic circuit inside the circuit starts oscillating when, an object is present at some distance from the sensitive side of the sensor. The threshold circuit identifies the rise and fall of such oscillation and drives an amplifier to operate an external load. The operating distance is regulated by the screw present at the back of the sensor. These sensors respond the same way to all conductors as these are not sensitive to the material changes and are also not a good choice in dirty or wet conditions.

Application

Capacitive sensors are used in pipeline and vessel leak detection as they can sense both metallic and non-metallic materials. They are also used in applications to control the level of liquids and solids and in pile-up controls in the automation industry.

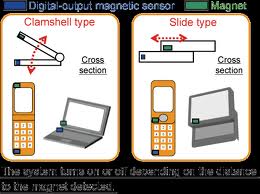

Magnetic Sensors: These proximity sensors work in the presence of a permanent magnet. These work on the principle of usage of reed contacts. A reed contact consists of two low resistance, ferro-magnetic reeds enclosed in a glass bulb filled with inert gas. An electrical contact is created due to the reciprocal attraction of both the reeds in the presence of magnetic field. The best thing about this sensor is that apart from measuring the proximity of a device, these can also be used to measure speed and the position of the devices.

Photoelectric Sensors: A photoelectric sensor is a device that uses a light transmitter (usually infrared) and a photoelectric receiver to detect the presence of an object, its absence and its distance. The light beam is modulated at a particular frequency and the detector that has a frequency sensitive amplifier responds only to the modulated light at that frequency eliminating the false imaging that is otherwise caused by a lamp or sunlight.