“The increasing availability of the CSP significantly impacts the ability of product designers to design handheld products of a size and weight not previously possible,” says Jain. The new CSP allows a higher density of components to be placed into an increasingly smaller portion of an existing PCB, or the PCB may be reduced with an accompanying reduction in product size, weight and cost.

Today, manufacturers are extensively using chip-scale packages along with different passive components to design devices such as palm-sized camcorders. This method helps to significantly minimise the time taken in transmission of signals since the components are placed closely. Consequently, this system produces a slew of faster circuits.

The smaller size of these components, along with their reduced weight, higher density and increased performance, has widely influenced the technologies and techniques used to assemble PCBs.

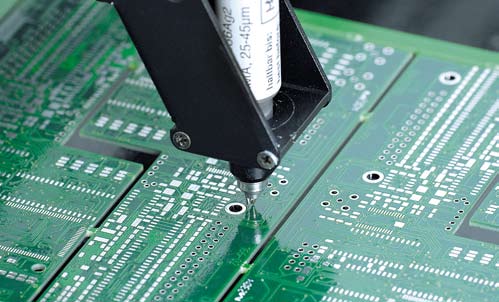

Assembly and component placement

Assembly techniques are becoming more and more precise, with demand for both smaller size and fine-pitched lead spacing. The entire gamut of placement machines and printers now addresses stringent requirements for speed and accuracy, notes Gurjal.

In spite of advancements in surface-mount technology, majority of circuit boards still contain a variety of through-hole components. Their electrical performance and mechanical requirements are satisfying enough, so these could not be completely thrown out of the scene.

Through-hole components such as connectors, electrolytic capacitors, power diodes, relays and transformers are odd-form in nature. (Odd-form stands for components with such a height, weight or shape that these cannot be placed automatically with standard pick-and-place machines.) Usually, odd-form components have been placed on circuit boards using discrete insertion machines, dedicated hard-tooled automation or manual assembly. Discrete insertion machines are best suited for applications with several odd-form components. Dedicated hard-tooled automation has been used to meet the needs of high-volume, low-mix manufacturing. Mixed-technology circuit boards continue to challenge the odd-form assembly process.

[stextbox id=”info”]As technology is advancing, SMT components may have short pins or leads of various styles, flat contacts, a matrix of solder balls or termination on the body of components.[/stextbox]

Component placement entails two main functions: pick-up and placement. In manual placement, the component parts are picked up either by tweezers or by a vacuum pipette.

“For passive components tweezers are best suited, but for multi-leaded active devices a vacuum pipette is very helpful to deal with component rotation and recommended when working with manual placement of components,” says Jain.

Today, automatic placement machines are required for high-volume production as the manual method turns out to be very slow. It is also possible to achieve consistent quality levels with automatic placement equipment.

Technology advancing

The overall trend is happening on the size side. “Size is still being reduced. Previously, bigger SMD packages like SOT89 were widely used. Now SOT 23 is commonly available,” says Gulabchand Hariya, managing partner, SMD Electro Components.

Product manufacturers are listening to customer needs and want to implement changes for smaller, lighter and less expensive components. A second phase to this continued reduction in package size and weight is currently being experienced.

“As technology is advancing, SMT components are becoming slimmer and slimmer, with very small leads or no leads at all. These may have short pins or leads of various styles, flat contacts, a matrix of solder balls or termination on the body of components. And the manufacturing process of surface-mount devices is becoming much more sophisticated,” says Chetan S. Thakkar, managing director, DS Electronics.

The challenges

With opportunities opening more avenues for SMT component manufacturers, there are challenges that follow closely behind. Reworking is one such area. It does no good to rework one component, only to disturb several others during the process. There is need of high accuracy for rework systems.

SMT has to shift from its traditional high-speed dominance to higher accuracies. Diagnosing and preventing flip-chip and wafer-level packaging defects will be the key to cost-effective volume package production. With wire bonding and flip-chip bumping being the two major interconnect techniques, understanding the stages of SMT component production is of utmost importance. However, during the inspection and handling of such components, the reduced size of devices and high-density requirements create new challenges. Fortunately, the production process of semiconductor packages has today got a boost from automated optical inspection systems.

Shiny future

The future for SMT is bright, as one can see just how lights changed to DIP LEDs and how DIP LEDs changed to SMD LEDs, and also how telephone handsets changed to mobiles.

“So every electronic gadget will become small,” says Hariya. Time is ripe for SMT equipment manufacturers to implement the silicon cycle into their manufacturing lines to get a complete picture of package manufacture and its requirements. In the future, SMT assemblers will also witness more of wafer- and substrate-level packaging demands.

“Today, chip designers face a very demanding flock of users, with a vigorous appetite for speed, bandwidth, functionally and so on. Hence, areas such as repair and rework are envisaging a lucrative growth,” concludes Jain.

That indeed sounds prophetic and, of course, futuristic for SMT—the small wonder!