There is a lot you can do with 3D printing. You can create doll houses and toys for your children, or decorative objects for your home. You can print chocolate in various shapes. Real food, like pizzas, can be printed in outer space, auto components can be economically and quickly printed, and limbs and other implants hastily created. Although most 3D printers are custom-made or sold with a heavy price tag today, things are on the verge of changing. In the coming years, a 3D printer will become one of those objects that we will own—simply because it does exciting things! How exciting? That’s the question we attempt to answer now.

Made for space, in space

Building things in outer space is a huge challenge as spaceships cannot carry the weight of equipment along with the raw materials. The way out is to 3D print all the stuff in outer space itself. California-based Made in Space (MIS) has shown that it is possible.

MIS owns and operates the Additive Manufacturing Facility (AMF)—a fully-functional 3D printing set-up that reached the International Space Station (ISS) in March 2016, and has since been producing various parts for MIS’ customers. But, why would one want to produce parts in outer space? The company believes that the space environment is unique, with its persistent microgravity and vacuum conditions. Manufacturing and assembling components in space widens design possibilities and enables one to extend the life of existing on-orbit assets or entirely new structures.

Take the example of optical fibre. The company claims that when exotic optical fibre is produced in a strong gravitational environment, such as Earth, it is subject to some flaws. Tiny crystals appear in the fibre and significantly increase signal loss.

According to them, “In space, ZBLAN optical fibre can be produced without these crystals, providing superior data transmission capabilities compared to both Earth-produced ZBLAN and traditional silica fibre optic lines. This microgravity-produced fibre has numerous applications, including transatlantic telecommunications, high-speed Internet, lasers, as well as enhancing technologies in space.”

MIS proved the possibility by launching a miniature fibre-pulling machine called MIS Fiber, with a payload of ZBLAN preforms supplied by Thorlabs. After being set-up on the ISS, MIS Fiber, remotely operated from Earth, successfully produced high value-to-mass ZBLAN fibre. It returned to Earth with its produce.

Made in Space’s Additive Manufacturing Facility (AMF) is the first ever manufacturing service in space (Courtesy: Made in Space Inc.)

As a next step, MIS is now developing Archinaut, which adds robotic arms to their manufacturing set-up so that the parts produced can also be assembled in space. This can be used to build new structures or to repair existing satellites and other space structures.

3D printing in space has some palatable uses too. BeeHex, a start-up funded by NASA, has developed a 3D printer that can print pizzas with edible ink. Astronauts need to choose the size, dough, topping and cheese, and the printer gets to work depositing layer after layer of ‘ink’ to create a pizza which is then baked in a 400-degree pizza oven. The pizza gets ready quite fast with minimal user intervention, so the company hopes that eateries on Earth will also utilise their tech!

The ultimate in JIT inventory

Moving beyond the hobbyists’ zone, 3D printing is now well-rooted in industrial spaces too. The ability to manufacture the required parts just when these are needed could mean the next generation of just-in-time (JIT) inventory management. Automakers and others would no longer have to depend on vendors to meet their commitments.

Volkswagen Autoeuropa, an automobile manufacturing facility, has seen such benefits by using Ultimaker’s desktop 3D printers to produce custom tools and parts, like gauges, jigs and fixtures. This is just a desktop 3D printer and not a large-scale industrial one, yet the benefits are clear. In a press report, Autoeuropa shared how they were able to 3D print a wheel-protection jig for around $20. Had they gone to a vendor, the process could have cost more than $850. By printing around a thousand parts, they claim to have saved $160,000 in 2016.

Apart from reducing cost and improving customisation and productivity, 3D printing allows unlimited and on-demand design revisions, faster lead times and increased accessibility. Since only desktop 3D printers have been used by Volkswagen, the investment is quite low compared to the savings. It is also easy for workers to learn, and quite scalable.

When it comes to mass manufacture of plastic parts, experts feel that 3D printing is not as economical as injection moulding. So, it is likely to be used only for customised parts. However, when it comes to printing metal parts, it could be a game changer.

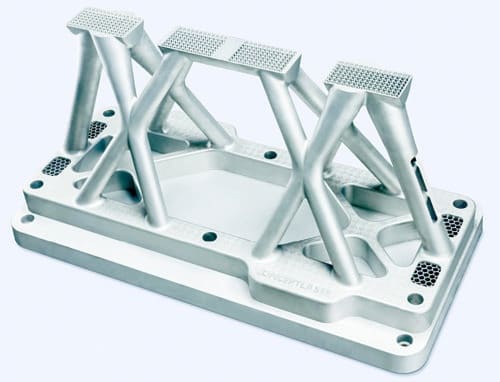

Markforge’s Metal X 3D printer can print metal parts overnight (Courtesy: Markforge)

At CES 2017, Greg Mark, CEO of Markforged, showed off the Metal X desktop printer, which can print using metals like 17-4 stainless steel, 303 stainless steel, 6061 aluminium, 7075 aluminium, A-2 tool steel, D-2 tool steel, IN alloy (Inconel) 625 and titanium Ti-6Al-4V. The designs are printed in metal powder surrounded by plastic, then the plastic is dissolved and the metal sintered, leaving behind a strong metal part.

Metal X uses a technology called Atomic Diffusion Additive Manufacturing (ADAM), which, the company says, is at the intersection of 3D printing and metal injection moulding, and blends high part quality with complex available geometries and high density. Rapid sintering using a microwave furnace speeds up the printing process.

Metal X is expected to be available in markets later this year. The company plans to continue working on ADAM technology in the future, incorporating it into a line-up of even more affordable and scalable printers, with the ‘blade server’ concept for volume manufacturing where printers on a rack will scale up or down to meet customers’ needs, as they do in current server farms.

General Electric is working towards building the world’s largest laser-powered 3D printer to make parts out of metal powder. This printer is bound to be useful for automotive, power, oil and gas, and other sectors. The company plans to showcase a prototype of the printer, called Atlas, in November this year. The printer can print objects up to 1m in two directions (length and width) using titanium, aluminium and other metals. So, automotive manufacturers would be able to manufacture an entire engine block for a car or truck. The production version is likely to be launched next year.

The Prodways Group, a French player, has also announced a new 3D metal printing technology called Rapid Additive Forging (RAF) that can produce large-scale metal parts. RAF is a type of directed energy deposition that prints metal within an inert gas chamber, using a robot with a metal deposition head. The metal gets deposited layer by layer, enabling near-net-shape objects to be printed in a few hours. These objects are then machined to final specifications.

Prodways has tested the platform with a variety of metals, focusing on titanium for use in aerospace applications. It claims that the method can produce parts without porosity and with greater mechanical resistance than methods like selective laser melting and electron beam melting. The current prototype can print parts of over 70cm in size, but the final version is likely to print objects as large as 2m.

Atlas, a prototype of GE’s new printer, can 3D print objects up to 1m long in at least two directions, using titanium, aluminium and other metals (Courtesy: Concept Laser)

In June, Carpenter Technology Corporation announced the availability of their new Puris 5+ titanium powder for 3D metal printing. Made from TI-6AL-4V grade 5 titanium, the custom alloy enables maximum reusability without compromising on strength. It has an excellent strength-to-weight ratio and biocompatibility, and can withstand temperatures up to 800°C. However, what experts believe to be a significant differentiator is the alloy’s oxygen balance. If a metal powder is exposed to too much oxygen, it gets contaminated and rendered unfit for reuse. But, Carpenter’s CTO claims in a press report that their metal alloy provides simultaneous optimisation of powder recyclability and strength. Additionally, achieving the oxygen balance in the powder is easier, more efficient and more effective from the start and throughout the titanium powder lifecycle.

The industry is already keen to put Carpenter’s titanium powder to good use. Carpenter has partnered with 3D printing start-up Desktop Metal to provide the powders for use inside its material cartridges. Other companies like OR Laser, PyroGenesis and GKN Hoeganaes are also working on the production of metal powders for 3D printing. The aerospace industry is expected to be a key consumer of these powders, as it warms up to the idea of using 3D printed metal parts.

According to news reports, Russia’s nuclear energy corporation, Rosatom, is also moving towards using an advanced metal additive manufacturing technology to produce 3D printed parts for the nuclear sector. Their industrial metal 3D printer uses layer-by-layer selective laser melting, with metallic powders based on iron, titanium, aluminium, nickel, cobalt, etc. Others like GE Hitachi Nuclear Energy and Dassault Systems are also working towards 3D printed parts for nuclear plants.

Breakthroughs in medicine and healthcare

Titanium is being used increasingly by different companies to print hearing aids, vertebrae, spinal interbody devices, hip and jaw implants, etc. Recently, somebody even developed a mini-plate implant system to fix a person’s drooping eye.

In yet another development, SI-BONE received FDA approval for its iFuse-3D implant, supposedly the first 3D printed titanium implant for use in the sacroiliac (SI) joint. The implant is placed between the ilium and sacrum bones on each side of the pelvis.

SI-BONE has developed a proprietary 3D printing technology in order to develop the implant. The implant features an enhanced porous surface that resembles the trabeculur structure of cancellous bone and a unique fenestrated design; both of these features combine to make an environment that promotes bone ongrowth, ingrowth, through growth and intra-articular fusion. The fenestrated structure and surface were specifically designed to promote intra-articular fusion and offer enhanced osteointegration.

Similarly, Additive Orthopaedics has received FDA clearance for its 3D printed minimally-invasive, intramedullary Bunion Correction System that helps to address alignment and stabilisation of bunions. According to a doctor, this 3D printed implant enables certain features in plates, which cannot be achieved through standard manufacturing processes. For example, one area of the plate can be made to provide additional fixation and strength, to enable the bone to grow onto and through the plate over time. This will support better integration and alignment of bones following a bunion procedure.

Johnson & Johnson, one of the popular names in healthcare, has tied up with companies like Organovo and HP to evaluate the use of 3D bio-printed tissues and other 3D printed healthcare solutions. They have also collaborated with Inkbit, a start-up spun out of the Massachusetts Institute of Technology (MIT), which has come up with a unique multi-material 3D printing technology to print complex consumer products with integrated electronics. In April this year, the group also acquired the 3D printing technology from Tissue Regeneration Systems Inc (TRS), to create patient-specific, bioresorbable implants with a unique mineral coating. These implants can be used to support bone healing in patients with orthopaedic and craniomaxillofacial deformities and injuries.

In June this year, a team of researchers at the Boston University College of Engineering revealed a potential treatment for ischemia using a cell-infused 3D printed patch that can guide the growth of new blood vessels. The team tied up with a Boston-based biomedical tech company called Innolign to 3D print vessels on a small scale of 100 microns. The cells had to be infused into the patches in a particular pattern in order to be effective, and that is where 3D printing proved its worth. The inherent flexibility of 3D printing allowed the team to change and test their designs, helping them to discern which patterns worked best. 3D printing also offers them the scalability needed to test their designs in larger, more complex organisms and tissue environments in the future.

From shoes to electronics, everything can be 3D printed

A four-year-old company called Carbon has come up with a photochemical process that uses light and oxygen to produce objects from pools of liquid polymer. This enables faster printing, greater structural integrity and better consistency than conventional methods. The technology is based on stereolithography (SL).

Objects are constructed layer by layer by shining a light into a pool of resin and then hardened into the desired shape. In SL methods, after each layer is printed, the object has to be lifted a microscopic level off the build plate to add another layer. This makes the process slow.

On the other hand, Carbon uses a clear, contact lens-like window in the resin pool, which is permeable to light and oxygen. According to the company, this creates a carefully choreographed balance between the light, which hardens the resin, and oxygen, which inhibits hardening. As a result, the object is created continually, without the need to add layers. This also makes it possible to create truly isotropic objects, which have same characteristics on all three axes. Adidas has tied up with Carbon to produce lightweight and durable midsoles for its 4D line of athletic sneakers.

In June, the Korea Electrotechnology Research Institute (KERI) announced the development of a 3D printing technology capable of printing highly-conductive multiwall carbon nanotubes (MWNTs), which will be very useful in wearables, flexible displays and other such applications. The meniscus-guided 3D printing of highly-conductive MWNT microarchitectures exploits rapid solidification of a fluid ink meniscus formed by pulling a micro-nozzle. The team has designed a polyvinylpyrrolidone-wrapped MWNT ink with uniform dispersion in order to achieve smooth 3D printing without any nozzle clogging. This technique gives scientists a lot of control over the printing process, and can be used to print a variety of microstructures with a high concentration of MWNTs.

Optomec, another global leader in 3D printers, has two unique technologies up its sleeve—Aerosol Jet and LENS. Aerosol Jet is used to 3D print electronics at the micron level, while LENS is a metal printing solution that can be added to computer numerically controlled (CNC) machining systems. Aerosol Jet is an additive manufacturing process that works with a variety of dielectric, conductive, semiconductor and biological inks. It uses aerodynamic focusing to accurately deposit electronic inks onto substrates, printing features ranging from 10 microns to millimetres.

The robotics industry is also an avid user of 3D printing technology. Nanoracing is a two-year-old start-up that makes mini racing drones. Their drones are 3D printed, with absolutely no screws or joints. All the electronic parts fit perfectly into a cavity in the drone.

In an interview with Sculpteo, a company that 3D prints Nanoracing drones, one of the co-founders of Nanoracing explained that 3D printing is an outstanding tool for prototyping and short-run production. “That’s what we offered our first clients: an early bird short run of 320 products. And for us, 3D printing allowed us to do the tests, the crash tests, and adapt the product. All of this while avoiding the costs and delays that go along with injection moulding: rheology tools, moulds, injection, and the validations between each step.”

Another robotic venture worth a look is InMoov—an open-source, life-size robot made with 3D printed components and controlled by Arduino microcontrollers. Although it is now around five years old, it continues to excite the community. It’s amazing because you can download the designs and print your own robot too if you have access to a 3D printer!

Indeed, 3D printing opens up a world of opportunities, for everybody and every industry. In India, it might still be too costly for you to own your own 3D printer. However, costs are going down. There are 3D printers like the da Vinci Mini that are priced around ` 40,000, and organisations can invest in these for learning and innovation.