Nowadays, adulteration is being done in sophisticated ways that demand cutting-edge research for the detection of adulterants.

Due to changing social values where companies are focussing on reaping rich profits, adulteration is prevalent in almost all commodities such as food items, fuel, cloths and construction materials. Adulteration has reached alarming levels and is, hence, making detrimental effects to the well-being of humans.

Innocent lives are lost when infrastructures like flyovers, bridges, buildings and roads face unexpected collapses due to the use of sub-standard construction materials. The biggest paradox is that people who are involved in adulteration never think that they or their near and dear ones could also be the victims of this menace.

Food adulteration

Adulteration of food not only involves intentional addition or substitution of specific substances, but also biological and chemical contamination. The most common form of food adulteration is the addition of sub-standard substances (adulterants) to increase the quantity of raw or prepared food items.

Adulteration can happen at any level, from production, processing, storage to transportation and distribution. People involved are not concerned about the negative effects adulteration can have on the health of consumers. This article focuses on the development, use and benefits of electronic and optoelectronic devices to check food adulteration.

Electronic nose

Human beings do not have the foresight to detect adulteration. Hence, scientists have come up with various technologies to check the same. Most traditional methods to check adulteration in food items make use of chemicals and thermal routes, which could not only fail but are complicated and difficult to use.

In this electronic era, electronic devices have influenced almost all aspects of life including medical, entertainment, safety, sports, education and defence. Electronic sensing is set to play a great role in checking adulteration of not just food items but other commodities as well.

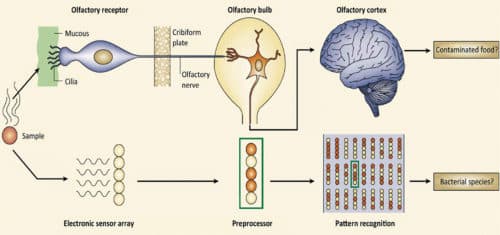

Electronic sensing is not limited to reproducing human senses using sensors and pattern-recognition systems. The various stages of electronic sensing for recognition process are similar to human olfaction. These are performed for identification, comparison, quantification and other applications, including data storage and retrieval.

In the last few decades, electronic sensing technologies and devices have undergone significant developments from technical and commercial points of view. Research has led to the development of various low-cost, low-capacity and more advanced electronic sensing devices such as electronic nose (e-nose).

An e-nose can detect and recognise odours and flavours with a high level of reliability. Using a number of electronic sensors, it can detect and differentiate between complex mixtures of volatile compounds. The technology can be utilised to differentiate aromas of food and related materials.

Electronic nose technology, along with food adulteration detection technology, is successfully being used in the detection of plant diseases and pests. Some of its advantages are operational simplicity, non-destructivity and bulk sampling. However, it comes with certain drawbacks as well, such as low sensitivity and specificity in comparison with micro-biological and molecular methods.

e-Nose technology is still in development phase, both with respect to hardware and software. e-Noses contain an array of sensors (from one to 32), using a variety of sensor technologies like organic polymers and metal-oxides to micro-balances. These are being widely used by some companies as quality-control instruments. Their strengths include high sensitivity and correlation to human sensory panels for many applications.

Limitations to their full potential includes loss of sensitivity in the presence of water vapour or high concentrations of a single component like alcohol, sensor drift and the inability to provide absolute calibration, relatively short life of some sensors, necessity to do considerable method development work for each specific application and lack of being able to obtain quantitative data for aromatic differences. There is some evidence that sensors differentiate aromas based on relatively few compounds. In the future, a relationship between specific chemicals and a single flavour attribute may be achievable.

Optoelectronic sensing

Optoelectronics is the discipline of electronics that focusses on light-emitting and light-detecting devices. Optoelectronic devices and components operate on both light and electrical currents.

Optoelectronics-based technology refers to electronic device applications for the sourcing, detection and control of light. It encompasses design, manufacture and study of electronic hardware devices that, as a result, convert electricity into photon signals for purposes of sensing, medical diagnostics, telecommunications and general science, among others.

Optoelectronics deals with radiation, its detection, creation and manipulation for various purposes. This includes x-rays, gamma rays, infrared (IR), ultraviolet (UV) and visible light.

Optoelectronic devices are basically transducers that convert electrical or optical forms of energy into one another. These can either be electrical-to-optical or optical-to-electrical. Thus, the devices act as detectors of light and transform detected light signals into equivalent electrical signals for computer processing.

Quantum mechanical effects of light on semiconducting materials used in electronic devices based on optoelectronics are as follows:

Photovoltaic or photoelectric

This involves direct conversion of light into electricity using solar cells.

Photoconductivity

This is an electrical phenomenon wherein a material becomes more conductive to electricity through the absorption of electromagnetic radiation such as IR, UV and visible light.

Stimulated emission

It is a process where a light photon interacts with an excited molecule, which causes it to drop to a lower energy level, resulting in the emission/liberation of an identical photon. This photon is transferred to the electromagnetic field used in laser diodes and quantum cascade lasers.

Radiative recombination. Here, electrons are transitioned from valence to conducting band in semiconductors, resulting in a carrier generation and recombination effect, which produces light.

Technological developments

Optoelectronic devices find applications in fields like military services, telecommunications, automatic access control systems, medical equipment and detecting food adulteration. The field covers a wide range of devices including LEDs and elements, image pickup devices, information displays, optical communication systems, optical storages and remote sensing systems.

Some optoelectronic devices that are currently making headlines are telecommunication lasers, blue lasers, optical fibres, LED traffic lights, photo diodes and solar cells. Some latest technological developments taking place in the field of optoelectronic sensing are summarised below.

- Suitable integration of advanced IR spectroscopy with chemometrics provides a powerful tool for adulteration detection.

- An electronic tongue is an easy and economic tool for the detection of adulterants.

- Biosensors with the ability to furnish real-time signals have been developed for the detection of urea in milk.

- An embedded optoelectronic sensing system consisting of AVR microcontroller integrated with optical sensor, LCD and keypad, making use of the change in refractive index parameter, can detect milk adulteration with an accuracy of about 95 per cent. This is an increase in accuracy of about 200 per cent over traditional methods such as spectroscopy.

- Fibre-optics-based optoelectronic sensing systems can be used for adulteration detection.

- Spectral changes in the grating response due to variations in adulteration levels can be used as investigative tools. The fundamental principle of detection is the sensitive dependence of resonance peaks on the changes in the refractive index of the medium.

- Surface plasmon resonance (SPR) can be employed as an alternative method to detect adulteration. SPR sensors offer the capability of detection of very low concentrations of adulterated chemical and biological agents in real time by monitoring.

Adulterants change the refractive index of food, resulting in corresponding phase changes. These changes can be detected at the output and related to the concentration of chemical species present at the point.

Shift of resonance angle as a function of adulterants concentration can be plotted with linear regression. The outcome has disclosed a real-time, rapid and non-destructive sensor to be promoted as well-developed.

Conclusion

Nowadays, adulteration is being done in sophisticated ways that demand cutting-edge research for the detection of adulterants. Conventional chromatography-based methods for the detection of chemicals are based on human observation and slow for real-time monitoring. Keeping in mind the limitations of traditional methods of different adulterants detection, electronic sensing is the technology to count on.

Further, optoelectronic devices are more sensitive, reliable and suitable to detect different types of adulterants. With growing concern about adulteration and strong footing in science and technology of optoelectronic devices, it is expected that, soon people will be equipped with cost-effective, environment-friendly, user-friendly, reliable, easy-to-operate optoelectronic sensing devices to check for any type and level of food adulteration.

Dr S.S. Verma is professor at Department of Physics, Sant Longowal Institute of Engineering and Technology, Sangrur, Punjab

Came to know the basics of adulteration

Nice article

Thank you for your valuable feedback.