Eyes, perfected by Mother Nature, are matchless display systems. Every other man-made display has some problem or the other—battery life, heat, glare, image quality and what not. However, humans never give up on their desire to out-do or, at least, match nature. And so, manufacturers and researchers continue attempting to improve the current display systems. They continue making these smaller, more flexible, power-efficient, panoramic, etc.

Moreover, ubiquity of devices has also led to the need for displays that are flexible and have a smaller footprint. Mobiles, wearables, augmented reality (AR) workspaces, immersive games and other applications throw challenges at the display industry to match their speed of travel into the future. What will the future displays look like? In this story, we dig into a few off-beat and futuristic research projects that give us a few clues regarding what displays might be like a decade from now.

Ole! Time to bend, roll and tango

Organic light emitting diodes (OLEDs) have been around for quite some time now. Having started their career with mobile devices, these are now beginning to be used in high-end large-size televisions, too. Made of organic materials that glow when subjected to electric current, these screens have laudable energy savings, resolution and form factor. More attractively, these organic materials are more flexible and make flexible displays a reachable goal.

Manufacturers like LG and Samsung are especially keen on bendy displays. A few years ago, Samsung demonstrated YOUM, a flexible active-matrix OLED (AMOLED) display that uses polyimide as the substrate material instead of glass. Polyimide is a polymer with high resilience and flexibility. Although Samsung has used this technology in a few of its curved phone screens, the impact has not been felt much. It was because most of these displays have been encased in toughened Gorilla glass.

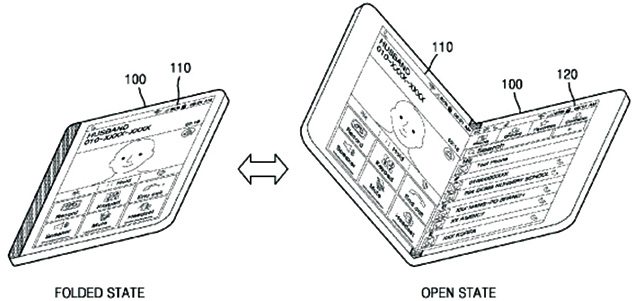

However, it is clear that the company is keen on flexible displays and hopes to use it to make jaw-dropping devices. A patent filed by Samsung and published by the US Patent and Trademark Office (USPTO) last November (Link) focuses on such scrollable, foldable smartphones and tablets. It describes a device that can be folded in half like a book, and another that can be rolled up into a cylinder.

The patent also hints at what the foldable device could possibly do in open and closed states. When in closed state during a call, the device would show the face of the caller and call-related options like recording, keypad and mute, while the open state will additionally have the contact list opened in the other half of the display. Other applications like messaging, images, etc, are also shown using the flexible display. Some images also suggest notifications being shown on the back of the screen when folded on the sides, or the corner.

LG is equally keen on flexible display tech. They showed off some beautiful tech at this year’s Consumer Electronics Show (CES 2016). Apart from a 45.7cm (18-inch) flexible display panel, they showed two smaller versions, one that was transparent and another that could be rolled up into a 3cm-radius cylinder.

LG claims that their new OLED displays are flexible enough to curve around walls or be used seamlessly inside cars. These are also thinner, lighter and break-resistant; so light that a thin magnetic strip is all that is needed to stick the 4mm-thick television screen to the wall and so convenient to peel off and stick somewhere else, as required.

The display produces its own light, so there is no backlight to add bulk to it. According to an announcement by LG, they plan to develop a 152cm (60-inch) ultra-high-definition (ultra-HD) flexible and transparent OLED panel with a transmittance of more than 40 per cent and a curvature radius of 100R, by 2017.

Of course, no race is complete without Apple in it! In 2015, Apple was awarded a patent (http://tinyurl.com/zsjoea4) by the USPTO for flexible, foldable electronic devices with force gesture control. According to Apple Insider, the patent describes a portable device, like an iPhone, that can be flexed, bent, folded or otherwise deformed without negatively impacting the sensitive internal components contained within. What makes this patent exciting is that it also describes flexible external parts, such as the chassis and cover glass, with pliable internal parts like batteries, circuit boards, displays and other electrical components.

Not only that, it also hints at an exciting new user interface using force sensors. Say, for example, users can squeeze the device to activate a command.

The patent also mentions bi-stable flex regions. This means the device can have two or more standard configurations. So what would Apple make with this technology? A phone that folds up like a hanky or maybe a phone that has displays on both sides? Well, we might have to wait for a few years to find out.

Self-repairing screens

Users with toddlers racing around the house would readily vote for this technology. Last year, a team of chemists led by Duncan Wass of Bristol University, England, revealed a technology that would enable smartphones and other screens to heal themselves.

Inspired by the way the body forms scabs to protect wounds, this new technology involves adding a healing agent, basically a chemical formula, to materials used for developing display screens, or even other products like nail varnish or wall paints.

This healing agent is made of different carbon based chemicals and produces a sheet of millions of microscopic spheres. When there is a crack in the display screen, it breaks apart these hollow microspheres, and a liquid is released that moves into the newly-formed gap. A subsequent chemical reaction causes this liquid to harden and seal the crack automatically, without any intervention from the user.

At a top-level, it looks as if including this technology into existing products would only involve a small manufacturing tweak, of adding the healing agent to the material used. However, experts feel that new challenges might crop up when one starts delving into the details. The tech, for example, might require some adaptation to fit into cutting-edge flexible displays. However, it is definitely a good start and would save users a lot of money in replacing broken screens.

Display that touch you

Displays seem to be incomplete without touch technology these days. As more and more devices fill the world, people want more natural forms of interacting with these. Since the past few years, there has been a lot of interest in haptic touchscreens, that is, screens that give you some form of sensory feedback.

Senseg is one of the pioneers in the field. Although not yet mainstream, their technology is lauded by experts and is constantly evolving. It lets the user feel reactions. Was the button-click accepted? Was there an error? Is the call going through? All this can be felt through pulses or pressure exerted by the screen on the fingertips. Senseg is promoting the technology for use in automotive applications, where getting haptic feedback will reduce the necessity for the driver to look at the screen, thereby reducing distraction.

Bosch’s haptic display, Neosense, apparently goes a step further, according to professional reviewers who tested it at CES 2016. According to reviews, Neosense lets you feel textures. Assume a system that has buttons designed with different textures, namely, coarse, silky, ribbed, etc. By moving your fingers over these, you can feel the different textures or patterns. This means that you can identify the required buttons simply by touching these.

Neosense also uses a vast array of pressure sensors to accurately differentiate between an intentional button press and brushing of fingers across the screen while searching for the right option.

Well, displays that let you feel textures would be a boon, especially for developers of learning systems and e-commerce portals. Imagine the day when customers can feel fabric on the screen while shopping for clothes!

Apple, too, has a bagful of haptic-feedback technologies like 3D Touch, Force Touch, Taptic Engine inside Apple Watch and vibration patterns for ringtones and notifications. However, haptic tech firm Immersion has filed lawsuits against Apple claiming that these infringe on Immersion’s patents.

Will graphene and graphics get along

Since its discovery in the early 2000s, graphene has been touted as a magic material that has the potential to disrupt many an industry. It is basically a single-atom thick layer of carbon, achieved by shaving off layer after layer off graphite. Scientists propose innumerable uses for graphene, right from optics to semiconductors.

Tomas Palacios, who heads Centre for Graphene Devices and 2D systems at Massachusetts Institute of Technology (MIT), is one such scientist exploring the applications of graphene. He has several radical ideas, of which one is described by him as display on demand.

He believes that graphene could turn everyday objects like coffee cups and shoes into devices that can easily compile and transmit information. “Basically, everything around us will be able to convert itself into a display on demand,” he said during a newspaper interview.

To implement this, his team is developing a 3D printer that uses graphene as its ink. These objects would have electrical intelligence built into these. Graphene with its electrical and optical properties could enable the object itself to turn into a display when required.

There have been earlier attempts to make awesome displays with graphene. Researchers from University of Manchester and University of Sheffield, for example, came up with a prototype semi-transparent, flexible, grapheme based LED display that could be used in phones, tablets and even televisions. The super-thin display was just 10 atoms to 40 atoms thick and could emit a sheet of light across its entire surface.

Samsung, which has developed a method of synthesising large-area, single-crystal wafer-scale graphene, also believes that graphene is the perfect material for use in flexible displays, wearables and other next-generation electronic devices. There are rumours that the company is already testing graphene based touchscreens.

Bodle’s bid for power

If flexibility is one requirement for future displays, then power efficiency is equally important. If you are bound to have devices all around you, you would certainly not want to keep charging all of these.

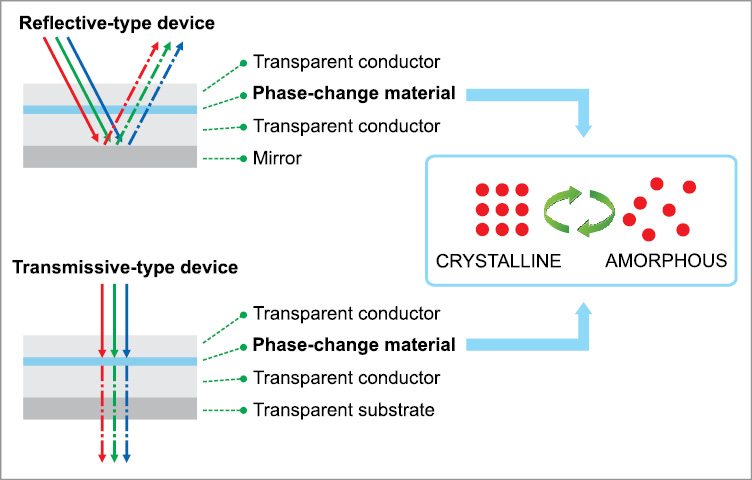

Bodle Technologies, a UK based startup, is working on a technology that could be used to make super-efficient displays that require almost no power at all. Their tech revolves around ultra-thin structures made using well-known and well-characterised materials including phase-change materials. This structure can manipulate light using electrical, optical or mechanical means.

According to the company, “It can be used to filter, steer or dim light at a flick of a switch and, most importantly, consumes very little or no power after switching.” This optoelectronic framework based platform technology can be used for developing low-power, flexible displays, smartwindows and much more.

Personal home theatre, anyone

Head-mounted displays, which were clunky and cumbersome at one point of time, are now sleek, lightweight and power-efficient. No wonder these devices, like Samsung GearVR, are touted to be more than gaming devices. These virtual reality (VR) displays have the potential to turn into personal home theatres, giving you an immersive, comfortable and personalised movie experience.

However, holographic displays that are likely to become popular in the next five to ten years are likely to put today’s 3D, VR and AR displays to shame. Holographic and volumetric displays appear to give an object mass. So you actually feel as if you are reaching out and holding an object.

There are several types of holographic displays. Of these, augmented holographic displays, which embed 3D objects into your surroundings, as if these were real, are already here. Products like Microsoft HoloLens and MagicLeap are examples of augmented holographic displays that provide an interactive, customisable experience.

In another class of holographic displays, nanophotonic devices manipulate light to achieve moving, full-colour holograms. These devices manipulate light at the source rather than trick the eye using middleware like glasses.

Several teams across the world, including one at Griffith University, Australia, are trying to develop such systems using graphene oxides and laser pulses to control the refractive index and wavelength of light. A nano-photonic holographic display does not require glasses, which means several people can view it. It is also potentially scalable to any size. However, it needs a wall to work and cannot project onto thin air.

If projecting onto thin air is what you really want, then you will get that, too. A team of researchers from Aerial Burton and multiple Japanese universities recently demonstrated a system that projects pixie-shape holograms called Fairy Lights into thin air. What makes these holograms all the more special is that these respond to human touch. The system uses femtosecond lasers, which can stimulate physical matter to emit light in 3D form.

Micro-LEDs to give OLEDs a good chase

Display experts consider micro-LEDs a technology worth watching. Micro-LED is an emerging display technology that uses arrays of microscopic LEDs as individual pixel elements. The tech offers benefits like greater contrast, faster response times and low energy consumption. While larger micro-LED displays are still too difficult to manufacture, experts feel that these displays make sense for smaller devices like smartwatches. That explains why Apple acquired LuxVue, a company working on micro-LED displays.

That said, perhaps micro-LED might emerge in larger formats. When John Rogers and Chris Bower of X-Celeprint proposed the use of micro-LEDs for multifunctional display systems at a conference last year, they first described a process for making multiple layers of LEDs with sacrificial layers in between that allow the layers to be lifted off. The company has developed a technology for transfer-printing of chips using elastomeric stamps utilising peel-rate-dependent adhesion.

If that does not make sense, let us turn to industry expert Kim Werner’s simplified explanation on Display Daily: “To oversimplify shamelessly, if you place the stamp on the layer of chips and peel it off quickly, the chips adhere to the stamp. Impress the stamp on the target substrate and peel it off slowly, the chips adhere to the target. This is also impressive, but it still does not create LED arrays any larger than the original lattice-matched arrays.

“As it turns out, it is relatively simple to impose patterns on stamps that result in picking up every tenth, twentieth or nth LED before depositing these on the substrate. In this way, you can go from the dense array of the original wafer to a sparse array on the target substrate. In principal, this allows you to make µ-ILED displays of virtually any diagonal.”

Using this technology, X-Celeprint has made 150mm stamps. According to Bower, making larger ones is just a matter of engineering, not science.

Nature-inspired display tech

The very concept of display is in many ways inspired by nature. No wonder scientists continue to observe nature—from the butterfly’s wings to the woodcock’s 360-degree vision—to develop better display systems.

In one recent venture, scientists from Harvard University and MIT learnt a few lessons from a type of mollusc called the blue-rayed limpet. Limpets have two optical structures within their shell. These are configured to reflect blue light while absorbing all other wavelengths of incoming light, resulting in a blue-striped appearance.

In an attempt to understand where the stripes came from, researchers decided to take a close look at the translucent shells using 2D and 3D structural analysis to reveal the 3D nanoarchitecture of the photonic structures embedded in the shells. The shells’ top and bottom layers were relatively uniform, with dense stacks of calcium-carbonate platelets and thin organic structures.

As they got about 30 microns under the shell surface, they found regular plates of calcium-carbonate morphed into a multi-layered structure with regular spacing between layers, like a zigzag pattern.

This could potentially serve as a design guide for engineering colour-selective, controllable, transparent displays that require no internal light source. This technology can be used in windows and glasses, which need to be transparent and at the same time overlay AR content, like say, a map. In a news release, one of the researchers said, “We believe that the limpet’s approach to displaying colour patterns in a translucent shell could serve as a starting point for developing such displays.”

Everywhere we look, there is another creature that inspires a better display, another device that needs a better display and another team ready to work on it. Indeed, there is a lot to look forward to in the coming years.

Do you like this article, you may also like these

Janani Gopalakrishnan Vikram is a technically-qualified freelance writer, editor and hands-on mom based in Chennai