In this article, we discuss cobots and AR from the perspective of motivation, technology and business, while adding a social spin to these.

Cobots (or collaborative robots) and augmented reality (AR) are advancing societal development. Cobots are finding use in sectors like manufacturing and medical for detecting errors and increasing productivity and, hence, motivating entrepreneurs to actively use these technologies.

When robots flooded the manufacturing sector, cobots came to the rescue. AR projects were established, which further enhanced and eased manufacturing. Even as robots demonstrated timely use of tech infrastructure, cobots eliminated the drawbacks of robots.

There are several examples of how cobots and AR have come to the aid of society in times of need. Developed in difficult times, today these are the silent tech heroes of the world. Cobots have received celebrity status, while AR is doing its job quietly to benefit society. Some companies/technologists develop these solutions as a part of their corporate social responsibility (CSR) initiatives, while others do it for personal satisfaction. Then, there are entrepreneurs who manage to implement such socially-beneficial solutions with a profitable business plan—although, this calls for a fine balancing of reach and pricing.

In this article, we scan through such technological solutions from the perspective of motivation, technology and business, while adding a social spin to these.

Cobots and AR are new platforms to connect technology and society

Cobots are essentially cooperative robots, intended to physically interact with humans in a shared work space. These were invented by J. Edward Colgate and Michael Peshkin, both professors at Northwestern University, in 1996.

Cobots are an improved version of robots. These deliver more accuracy to work, speed up tasks, and bridge the gap between manufacturers and customers. Current robotic systems are expensive and need more skills to operate. Whereas, training cobots is easy because humans can interact with these without using any programming language or script. This results in ill-equipped manufacturing systems being able to handle errors better.

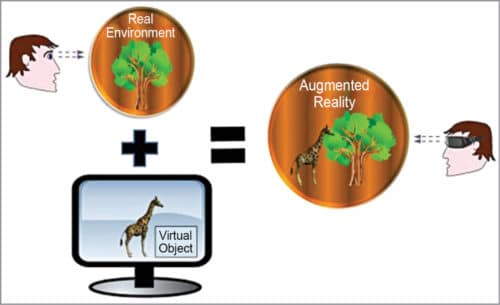

AR allows viewing of information that otherwise resides on screens or paper. It makes processes faster and more accurate. AR can be used with digital twin technology with a device model. It sets about exploring ways to improve information delivery to users.

Combining AR and cobots can lead to some interesting applications, further enhancing robot and human interaction. However, such systems are still in their research phase.

Popular examples of AR are WorkLink and Google Glass. Rittal is using AR at its research centre to assist tasks such as wiring, debugging and process control. The company is integrating AR with its EPLAN platform builder software. EPLAN is used to design and model almost everything, from wiring harnesses to control panels. An AR system can significantly reduce errors that may occur due to incorrect wiring, by showing user information with visual context. It can speed up wiring processes as well.

AR-based solutions are also being used for training. These reduce training times, because information is readily available. AR solutions depend on enterprise-class reality platforms that use speech recognition and voice biometrics to enable automatic information delivery and capture.

Cobots come in many forms. Modular individual transport (MIT) cobot can lift up to 500 kilograms. It comes with multiple drive and lift options. Multiple cobots can be synchronised for coordination of movement. The system can be equipped with sensors to avoid obstacles and aid navigation. MIT cobot can be controlled remotely or integrated with an autonomous guidance system.

Both AR and cobots are changing the face of industrial operations.

Apple and Google released AR software development kits (SDKS) for their respective platforms. Many mixed-reality headsets support this software framework, including devices from HP, Dell, Acer and Samsung.

In gaming arena, AR glasses provide an immersive video environment. Many AR devices that were showcased at Consumer Electronics Show 2018 can be utilised as a part of solutions, from simulating automotive experiences to control drones.

Then, there is Snappy, an AR app for smartphones, using which users can record geo-specific messages complete with animated AR characters.

Cobots can be used in controlled spaces like hospitals. Aethon’s Tug cobot has been walking around medical facilities for years. Tug’s lidar and other sensors are similar to Marble’s. The former uses Wi-Fi to communicate with doors and elevators. Aethon’s family of Tug cobots have found a home in controlled environments like hospitals, delivering everything from medicine to food.

Sophia, the famous humanoid cobot, has the world amazed by her gentle nature and compelling intelligence. Developed by Hong-Kong based Hanson Robotics, Sophia is quite a marvel to watch. Saudi Arabia even offered her citizenship.

Rethink Robotic’s Sawyer is an armed cobot designed to operate in close proximity with humans. Like many cobots, Sawyer detects humans through sight, sensors and touch. It also has limbs that maximise its powers. Sawyer comes with a counter weighted arm for low-impact operations.

Easy movement of arms by a person is one way of programming cobots like Sawyer and Baxter. It enables their training programs to move the arm around, adjust grippers, manipulate objects for the camera and so on.

Feston’s Bionic cobot is a pneumatic robot that has seven joints.

Types of cobots

There are four types of cobots, as defined by ISO/TS 15066 standard. These are power and force-limiting, safety-monitoring, hand-guiding, and speed and separation monitoring, with most people focusing on just the first.

The main difference between a power and force-limiting cobot and the other three is that the former can use regular industrial robots with additional sensors and still be totally safe for human-robot collaboration. The power and force-limiting cobot represents robots that can sense forces and stop to avoid injuries. It has all kinds of sensors embedded in it.

Force-limiting cobots are of following types:

Joint-sensing

It is the most common type of cobot that includes robots like Universal Robot (UR 3, UR 5 and UR 10) and KUKA (IIWA). It uses joints to monitor the forces applied to its body.

Force-sensor base

This cobot has a different way of feeling the forces applied to its body. As the name suggests, large force-torque sensors at its base monitor the different forces. However, playload needs to be set correctly to allow the robot to compute whether the force applied at the force sensor is higher than the weight it is supposed to handle. This means that a force-sensor base robot is more complicated to use than a joint-sensing one. But, it is safer and more precise.

Skin-sensing

This force-limiting robot is not as widespread in the industry, but is probably the safest option out there. Robots like Bosch (APAS) use tactile sensing (of all kinds) to detect impact. Sensors monitor the conductivity of the robot’s body and instructs it to stop once it reaches a certain threshold.

Inherently-safe

An inherently-safe robot may use any (or all) sensor(s). What distinguishes it from the others is that it cannot hurt users in any way.

Cobots and AR in India

The first cobot arrived in India in 2011, when Bajaj Auto deployed it in one of its factories.

Aurolab is a Madurai-based company that makes intraocular lenses. Earlier, lenses were made by humans, who manufactured 150 lenses a day. Using cobots, the firm now makes 10,000 lenses a day, exporting to 150 countries.

In automobile factories, cobots tighten bolts when a human worker places tools in front of them. In small-scale industries, these make drilling operations, while the human worker performs quality checks.

Cobots are simple to use, and can be programmed in 40 minutes. One cobot can cost between ` 1.4 to ` 2.2 million.

Denmark-based Universal Robots is a pioneer in advanced, user-friendly and light cobot arms. It is bullish on demand from India’s automotive market. The company that entered the Indian market in 2016 has sold and deployed more than 300 cobots till date. Out of these, vehicle manufacturers and component suppliers have brought 200 cobots.

Despite the slow adoption of AR technology, the Indian AR market is expected to grow at a compound annual growth rate of 76 per cent over the next five years, fuelled by demands from business and consumer sectors. Over the past few years, India has witnessed the emergence of 170 AR startups.

Cobots gaining ground

A cobot fulfils the fourth criteria of safe collaboration, which is force and limitation. It is a great handling assistant. It helps workers in transporting heavy loads from one point to another.

Traditional robots are heavy and bulky, and their rapid movements make these unsafe for human interaction. These need programming by highly-trained persons and, once installed, are rarely moved. These drawbacks are avoided by cobots.

Cobots are lighter, mobile, plug-and-play compatible and increase the safety of workers. Accounting for just a fraction of global industrial robot sales, these flexible robots have the potential to revolutionise production. Cobots can significantly reduce production cycle times from raw material to finished products.

Advances in gripper technology and artificial intelligence (AI) will help solve additional drawbacks of current cobots. For example, handling wires, textiles or changing tasks remain a challenge for industrial robots.

Using AR to aid users

Leaders of the industry are using AR technology to do amazing and revolutionary things with holograms and motion-activated commands. New York’s Museum of Modern Art’s fifth floor has turned into a personal AR playground. AR technology is opening new possibilities for activists and art enthusiasts, who are eager to change the museum-going experience.

AR supports industrial processes. Its use in the industry started in 1990s. Object recognition, computer graphics, AI and human-computer interaction are some areas where AR is typically used.

AR is an advanced version of virtual reality (VR). It has emerged as an innovative force in several high-calibre industries. AR is improving the digital world to improve the physical world. Projection AR technology is used to transform manufacturing and assembly processes at companies in many different sectors around the globe.

In hospitals, AR is not only changing the way doctors learn about human anatomy, but also helping them diagnose patients more efficiently. Instead of CT scans and endoscopic cameras, doctors now only require AR glasses that allow them to stay focused on their tasks, while being fed all the information they may need, virtually.

AR is a dominant force in the manufacturing industry. Projection AR has become standard on factory floors throughout the world. It is making factory floors smarter, safer and better, by increasing speed, precision and improving quality in manufacturing.

AR is making huge leaps in the education sector, too. It is making learning more enjoyable for children. It is also being used as a learning device in museums.

Many auto-makers use AR to design cars. Auto showrooms are increasing efficiency by tapping this technology.

In military, AR is frequently being used to enhance training, situation awareness, information processing/dispersion, safety and speed.

Retail, gaming and real-estate are other sectors where AR is being widely applied.

Although, AR’s primary application has been in gaming, it can find surprising new roles in robotic research, and may soon have a huge impact on manufacturing and logistics automation and, eventually, in home and service robots.

Vinayak Ramachandra Adkoli is BE in industrial production. He was lecturer in mechanical department for 10 years in three different polytechnics. Now, he is a freelance writer and cartoonist