Connected car is the buzz word today. In reality, the connected car already relies on the Ethernet also known as vehicles Ethernet. From infotainment systems and backup camera connections, the Ethernet’s high capacity and versatility readily penetrates automotive segments.

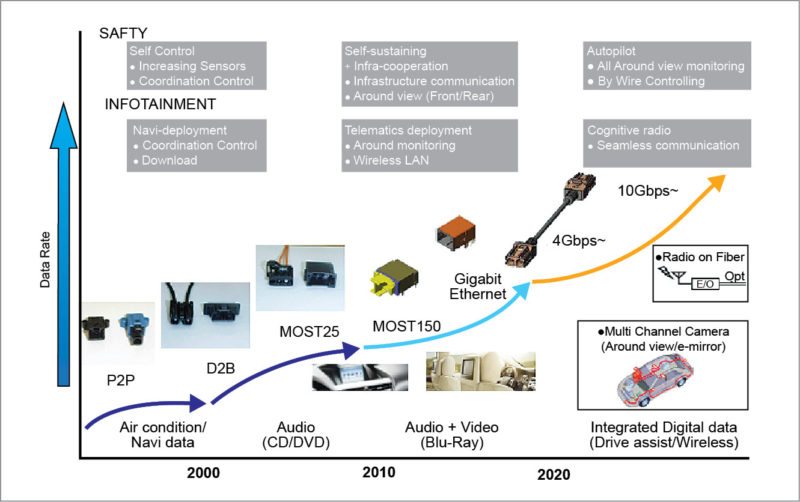

Ethernet migration in the automotive market in 2016 is a new trend. The advanced driver assistance system featured in many vehicles is expected to expand the use of the Ethernet. Recent technological developments make the Ethernet viable for use in cars. As per estimates by Frost & Sullivan and Strategy Analysis, nearly 400 million vehicles Ethernet ports will be in use by 2020. By then, total number of vehicles Ethernet ports is expected to be higher than the total number of all other Ethernet ports combined.

Gigabit Ethernet is also in the pipeline in 2016. Emergence of 1000BASE-T1 standard in mid-2016 provides a roadmap for the vehicles Ethernet evolution. By 2020, it is estimated that 40 per cent of the cost of a car will be in electronics.

As automotive manufacturers are adding more and more computer based systems, applications and connections, cost of electronics content and the wiring harness to support these in terms of cabling, network interfaces and onboard computing power is growing. Ethernet deployment can, and will, reduce these costs.

Media-oriented systems transport (MOST) currently dominates as a dedicated high-speed multimedia network technology for auto infotainment systems. MOST bus, based on a ring topology, uses synchronous data communication to transport audio, video and voice signals.

With Gigabit Ethernet, it could support many more streams than MOST at a higher data rate in higher resolution.

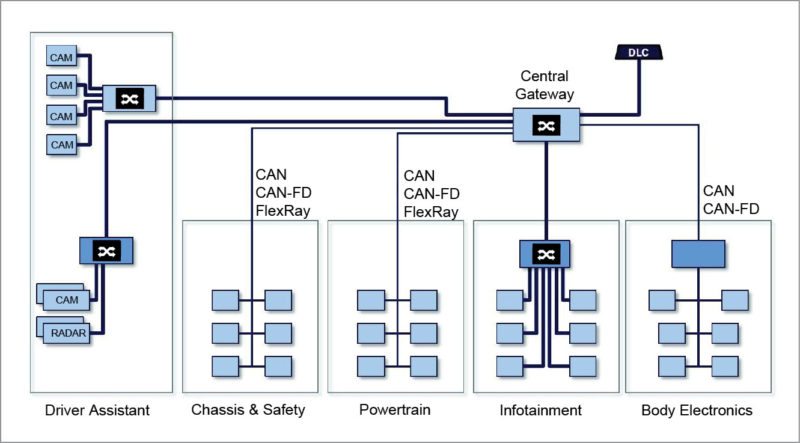

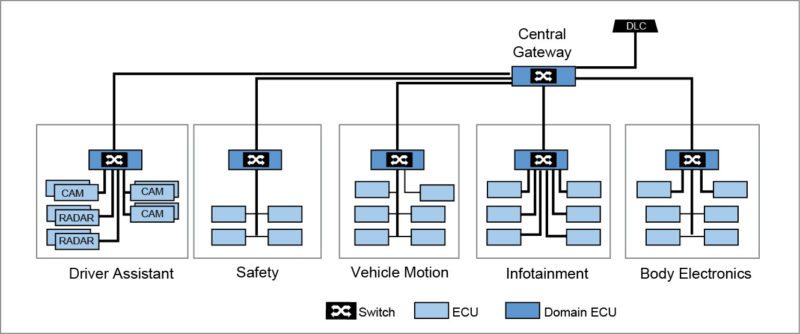

A vehicle today consists of an infotainment, advanced driver assistance system (ADAS) and control domains, each using MOST, Flexray, CAN, LIN, LVDS and the Ethernet. Even though the Ethernet has existed for over 20 years, it could not be previously used in automobiles due to the drawbacks like it did not meet OEM EMI/RFI requirements for the automotive market, was susceptible to alien noise from other devices in a car, could not guarantee latency down to the low microsecond range and did not have a way of synchronising time between devices and having multiple devices sample data at the same time.

Automotive Ethernet

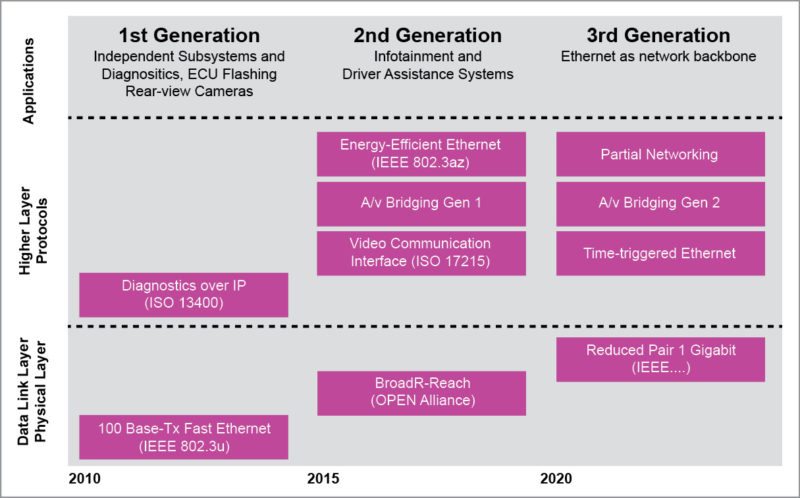

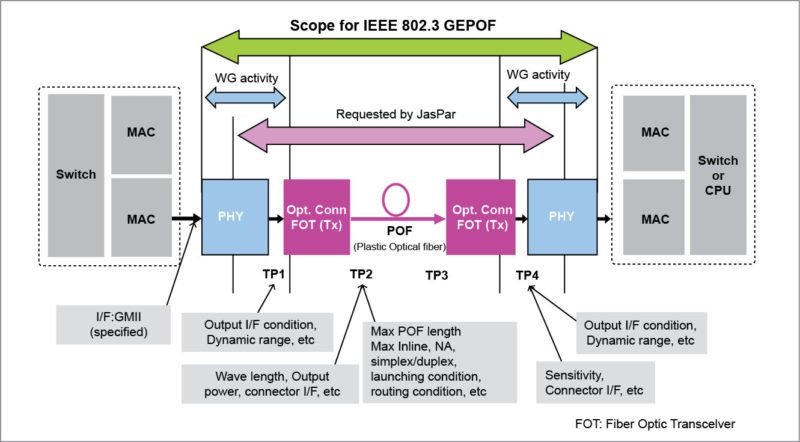

Automotive Ethernet is a physical network that is used to connect components within a car using a wired network. It is designed to meet the needs of the automotive market, including meeting electrical requirements such as EMI/RFI emissions and susceptibility, bandwidth requirements, latency requirements, synchronisation and network management requirements. IEEE 802.3 and 802.1 groups where multiple new specifications are listed and revisions to existing specifications are done to meet automotive requirements.

Automotive Ethernet, including 100BASE T-1 and 1000BASE T-1, is not like low-voltage differential signaling (LVDS), which is point-to-point serial connectivity. Automotive Gigabit Ethernet is capable of handling multiple video streams from many cameras. Other obvious places to use 1000BASE-T1 are in connecting multiple cameras and in a variety of infotainment systems. Main driving factors are cost reduction, efficiency and reduced time-to-market.

Technology has paved the way by developing a 100Mbit per second Ethernet physical-layer standard, specifically designed for automotive connectivity applications. It can run high-bandwidth data over a single-pair unshielded twisted-pair copper wire, cutting cable and connector costs, while reducing the weight of the wiring harness inside a car.

The standard’s layered approach enabled the development of new physical layer (PHY) specifications, media access protocols (MACs) and other capabilities, allowing it to keep pace with the demands of modern networks. Extensions to the original IEEE 802.1/802.3 standards now define practical solutions for providing security, deterministic performance, traffic shaping and many other application-specific functions, features and specifications. As a result, Ethernet has many capabilities that it needs to meet the unique demands of in-vehicle Ethernet networking.

One-Pair Ethernet

A proprietary PHY standard, BroadR-Reach, enables longer distances of copper Ethernet connectivity at 100Mbps (up to 700 metres). This PHY uses technologies from 1GE copper including multi-level PAM-3 signaling and better encoding (to reduce the bandwidth required on the cable) and using echo cancellers, so bi-directional data could be transmitted on a single pair. Due to the lower bandwidth (~27MHz bandwidth, 62.5MHz for 100BASE-T), this standard met automotive EMI requirements and Broadcom started marketing this to the automotive world.

As the industry realised that 100Mbps is enough for video transmission but not enough to act as a backbone in the car, it pushed for the creation of a task force for 802.3 (802.3bp) to define a standard for 1G over a single twisted pair for links of up to 15M for the automotive market. The new PHY is known as 1000BASE-T1 (where 1 stands for one pair). Based on current timelines, it is expected that prototypes will be available this year, and this will become a standard by 2017.

Power-over Ethernet

To further reduce the wiring needed in a car, Power-over Ethernet (PoE) may be used to power devices. IEEE 801.3bu (One-Pair Power-over Data Lines, or PoDL) task force is working on standardising PoE over a single pair. This is a minor modification to the current PoE, and this standard is expected to be approved soon.

Energy-Efficient Ethernet

A car’s electrical components do not all turn off when the engine is turned off. When the engine is off, battery capacity is limited. In order to minimise power consumption when the engine is off and when the engine is on, Energy-Efficient Ethernet (EEE), which turns off the network when not in use, is used. Those components that do not need to be powered on at all when the engine is off will have their network segments completely turned off. Those that need to be on will use EEE to minimise power consumption.

Gigabit Ethernet

A single-pair version of Gigabit Ethernet intended as a high-speed aggregation backbone for 1TCPE traffic reduces cable weight. It could also serve as a direct connection between network backbone and diagnostics, ADAS cameras, infotainment video and other applications with data requirements above 100Mbps.

It meets automotive system EMC requirements, supports 15 metres over unshielded automotive cabling. It has a standard Gigabit Ethernet MAC interface (SGMII/RGMII/GMII), which is defined through IEEE standardisation process. Gigabit Ethernet is targeting to penetrate the vehicle market in 2018.

Two essential factors are completion of IEEE standards and a roadmap for the future. With the completion of IEEE 100BASE-T standard, chip vendors expect to follow the trends in vehicles Ethernet. Upcoming 100BASE-T1 standard will be based on BradR-Reach specifications. Gigabit automotive Ethernet PHY transceiver chip is based on 1000BASE-T1 draft standard.

Advantages of 1000BASE-T1 are:

-

-

- Supports machine vision for ADAS and is suitable for high-speed video links

- Supports more video channels and can uplink 100Mbps domains

- Can use cost-effective unshielded cables

- Ethernet cables are lightweight and flexible

- Possibility to support 100BASE-T1 and 1000BASE-T1, and can define systems with choice of resolution by replacing a single module

- Adds video paths through software

-

Uncompressed high-definition video needs greater than 100Mbps. At 100Mbps, strong compression is required that can degrade images. Compression algorithms add latency, which limits the applications for the Ethernet. At 1Gbps, little or no compression is required. Low latency supports higher quality image transport. For machine vision, high-definition navigation and instrument cluster that has a high bandwidth compression algorithm are required.

The standard that defines 100BASE-T1 was developed outside of IEEE 802.3 committee’s governance. But it is strictly based on IEEE 802.3 framework. PHY is fully compatible with a standard Ethernet MAC that allows seamless interoperability with nearly any Ethernet-capable microcontroller or embedded system element, provided its MAC’s Media Independent Interface (MII) is compatible with One-Pair Ethernet PHY.

Maintaining compatibility also eliminates the need for any special drivers, making it easily interoperable with Ethernet devices that support IEEE 1588 remote timing and clock synchronisation protocol. Precise timing and synchronisation that IEEE 1588 provides will be critical in automotive sub-systems such as braking, engine control, active suspension and anywhere else where real-time operations are performed.

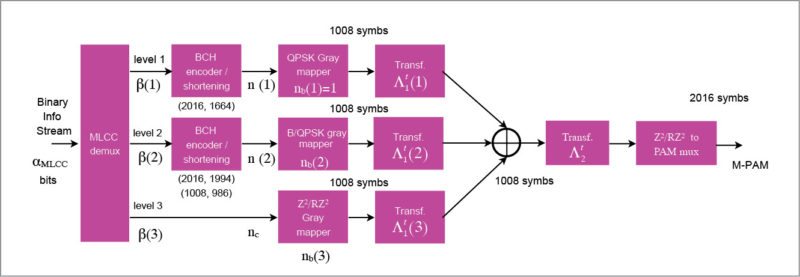

Incoming data is divided into blocks that are partitioned in up to three levels with different degrees of coding and then mapped to a 2D constellation. Bits in the first level are protected with a BCH code that provides powerful error correction, while the second level is protected with another BCH code and the last level is not coded. These are then mapped such that those from levels two and three are far apart (that is, coset partitioning).

The first level is always enabled by using QPSK modulation. The second level, depending on bit-rate configuration, uses BPSK or QPSK modulations. For BPSK, BCH code is shortened to 1008-bit length. The third level directly maps the information into configurable size modulations over Z2 or RZ2 lattices. After mapping, 2D lattice transformations are used to implement the coset partitioning. Finally, MPAM symbols are generated by time multiplexing from 2D symbols.

This is a process for configuration in which the numbers of bits in each level are 1,1 and 1.5. This corresponds to 16-PAM modulation and bit rate of 1Gbps, with symbol frequency of 312.5MHz. By using different numbers of bits at each level, multiple speeds can be obtained depending on channel conditions. This results in a flexible scheme that can adapt to many POF channels.

Transmission of data is structured in frames that are sent continuously. Each frame contains 112 data blocks (MLCC code words) and also additional information related to the physical layer. This information is in the form of two pilot signals (S1 and S2) and the physical header (PHS). Pilots are intended to aid the receiver in performing linear and non-linear equalisation and timing recovery.

Non-linear equalisation is implemented in the receiver while linear equalisation is implemented in part in the transmitter using Tomlinson-Harashima Precoding (THP) to avoid error-propagation issues, and in the receiver using a feed-forward equaliser. The physical header is used for physical-layer signaling, which includes selection of MLCC configuration and transmission of THP coefficients. GigaPOF scheme also provides good energy efficiency.

The Ethernet moves packets through networks on a best-effort, non-deterministic basis, which makes it poorly suited for use in mission-critical real-time systems used to control drivetrain or braking systems or support driver-assist functions. But later developments have added mechanisms like IEEE 802.1tsn (time-sensitive networking) protocol that provide assured, non-conflicting delivery of data and command packets within strict time parameters.

Additional standards for specific timing-critical applications are also available, including IEEE 802.1AS/802.1Q/802.1Qca protocols, which support transport, switching and management of latency-sensitive connections used in high-speed real-time control applications.

The next generation of infotainment systems will benefit from IEE 802.1AVB, which enables aggregation and distribution of audio/video streams. These capabilities rely on IEEE 1588 precision-timing protocol to provide timing information required by each node to keep its clock synchronised with the network’s master clock. IEEE 1588 is now providing precision-timing services in everything from small-cell wireless networks to industrial automation systems.

Various car makers currently use the vehicles Ethernet to transport video streams within their infotainment systems. But the vehicles Ethernet must cross the reliability gap from these applications, where a bus failure means an inconvenient loss of cabin comforts to being certified for safety-critical applications such as drivetrain, suspension or braking systems where failure is not even an option.

Bridging allows the vehicles Ethernet to peacefully co-exist with legacy sub-systems; even more as IEEE 802.1BASE-T1 and 1000BASE-T1 standards developments bring technologies like the two-wire Ethernet PHYs to the industry.

Other protocols like IEEE 802.1TSN Deterministic Ethernet standard will also play an important role, bringing precision, reliability and speed that the Ethernet needs to handle mission-critical automotive systems like advanced driver-assist and collision-avoidance systems and, ultimately, the car’s main system bus.

Many driver-assistance systems rely on getting data from cameras and other sensors in a timely manner. Unlike watching video on a computer, where buffering is used to compensate for the unreliable timing of the network, these systems require both controlled latencies and guaranteed bandwidth.

IEEE 802.1 Audio Vide Bridging (AVB) Task Group (renamed Time-Sensitive Networking Task Group) is working on standards to meet requirements such as 802.1Qat (Stream Reservation), a simple reservation protocol to notify various network elements in a path to reserve the resources necessary to support a particular stream.

801.1Qav (queuing and forwarding for AV bridges) defines the rules to ensure that an AV stream will pass through the network within the delay specified in the reservation.

IEEE also standardised IEEE 1722 (layer 2 transport protocol for time-sensitive applications in bridged local area networks) and 1733 (layer 3 transport protocol for time-sensitive applications in local area networks). These protocols use time (from IEEE802.1AS) as well as worst-case transport delay to get a presentation time, which is inserted in the packet.

1733 is used with RTP/RTCP and 1722 is used with IEC 61883 and other formats. AVnu Alliance is an industry forum dedicated to the advancement of AV transport through the adoption of IEEE 802.1 AVB and related IEEE 1722 and 1733 standards. This alliance is heavily supported by the automotive industry.

Test requirements

PHY testing. Testing has to be conducted in both 100Mbps (BroadR-Reach) and 1GE (802.3bp 1000BASE-T1) PHYs. Physical testing might have a variety of purposes, so that requirements of a specification are met. Testing demonstrates proof of concept, demonstrates utility of a proposed implementation, provides standard data for engineering or quality-assurance purposes and validate suitability for end use.

Switch testing. Vehicles Ethernet switches will need to test the new AVB and IET support capabilities. The test such as queue-reservation protocols, getting expected packet loss, bandwidth and latency for each class of service, behaviour test when a device connected to the switch is misbehaving, test for failover and convergence times, negative test cases and 2554/2889 testing with the above conditions are taken.

Security testing. Cars are becoming more connected and software-driven. Security is becoming more critical than ever before. Car manufacturers need to ensure that cars have multiple fail-safe systems to prevent intrusion, especially when it comes to power train domain.

Challenges ahead in vehicles Ethernet

One of the biggest challenges in creating automotive-grade vehicles Ethernet was finding an alternative to the multi-pair unshielded twisted-pair cabling commonly used by 100BASE-T and 1000BASE-T networks. Category-5/6 cabling is simply too bulky and expensive to be practical in the tight confines and tight budgets of high-production automobiles.

In order to meet the unique cost and manufacturability requirements of automotive applications, OPEN (One-Pair Ether-Net) Alliance Special Interest Group has developed a new PHY technology. It is being called 100BASE-T1 or 1 Twisted Pair 100Mbps Ethernet (1TPCE). It uses digital echo cancellation and decision feedback equalisation (DFE) techniques borrowed from 1000BASE-T Gigabit Ethernet to support full-duplex Ethernet at 100Mbps over a single pair of unshielded twisted wires.

Meanwhile, more widespread use of vehicles Ethernet could, in theory, increase the potential for hacking through a maintenance interface or in-car Wi-Fi hotspots.

Do you like this article? You may also like: click here

V.P. Sampath is an active member of IEEE and Institution of Engineers India Ltd. He is a regular contributor to national newspapers, IEEE-MAS section, and has published international papers on VLSI and networks