The concept of micro-mobility was best displayed in Segway. As this field of innovation expands its borders to two-wheeler and three-wheeler options, will the market accept this change? What is the technology that’s driving them?

The demand for shared mobility has increased over the past decades across various cities all over the world. Rather than just being used for recreational purposes, shared electric two-wheelers and bicycles have become an increasingly popular means of daily transport.

This concept of shared mobility has the potential to help local governments deliver clean, healthy, and efficient urban mobility. So they have been launched in many European and American cities and can now be seen in some Indian cities like New Delhi as well.

However, the challenge with two-wheeler and three-wheeler micro-mobility vehicles is that they do not utilise the parked time for charging when left on sidewalks and other public spaces. If the vehicles are charged while parked, it is possible to reduce the size of their batteries and increase their life as the batteries would be trickle charged in small batches rather than having a deep charge every night.

Wireless charging

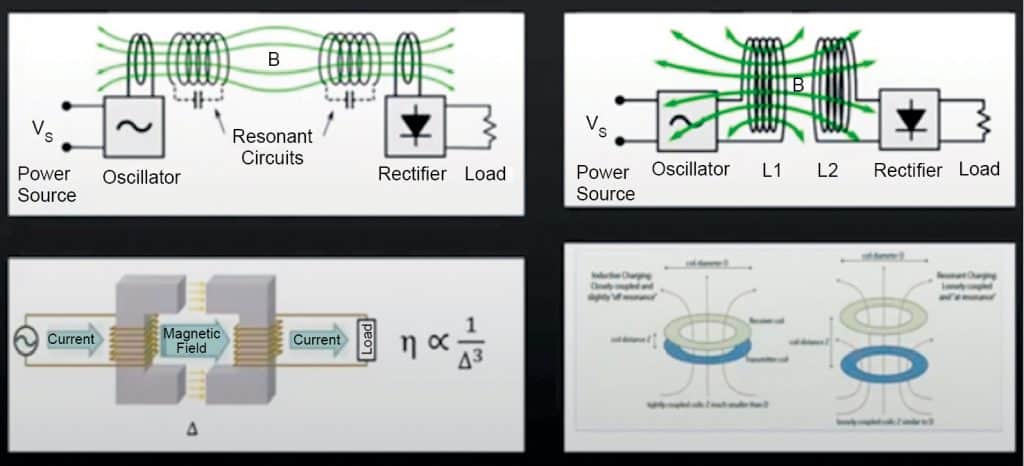

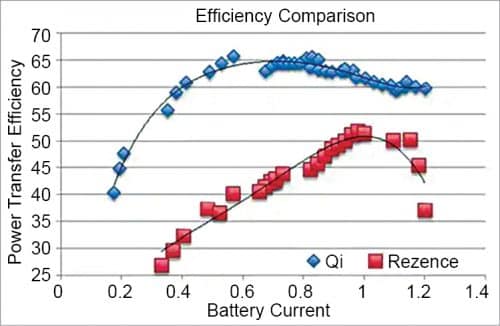

Wireless charging technologies are usually preferred to charge micro-mobility vehicles as they eliminate the need to plug in. Two types of wireless charging technologies exist, each having its own merits and demerits.

One is the Close Coupling technology in which the primary coil radiates energy and the secondary coil intercepts most of the magnetic flux. The separation, alignment, and sizes of the respective coils determine the coupling factor, which has a significant influence on the efficiency of the energy transfer. The frequency range of these systems is quite unique, as they start at high frequencies with light load and lower frequencies with higher load. This method provides high efficiency over changes in load.

The other technology is known as Resonant Inductive technology. The oscillating magnetic field generated by the primary coil induces a current in the secondary but also takes the advantage of the strong coupling that occurs between the resonant coils—even when separated by tens of centimetres. These systems have a sharp resonant frequency peak.

The optimum frequency, however, can change with load, separation, and presence of extraneous objects. Therefore, these systems require active frequency compensation in the transmitter, with more complex control and communication between transmitter and receiver. These systems may also cause electromagnetic interference for nearby electronic devices.

Inductive power transfer

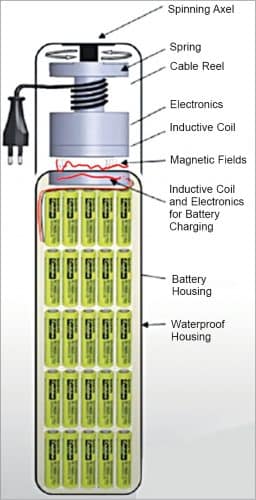

The inductive power transfer system used in micro-mobility elements is wireless, implying that the secondary coil present in the vehicle can be integrated with the battery pack in a completely sealed waterproof way. The whole solution is a controlled power supply that can talk directly to the battery management system on the vehicle itself.

Wireless inductive power transfer provides following benefits:

- Frictionless rotation with robustness of pulling out and coiling in of cable

- Hermetically sealed system to prevent corrosion and damage of parts

- Waterproof system that can be cleaned by high-pressure water

- Meet the present-day charging requirements and in addition has:

- Phone allocation giving status of charge

- Status of the batteries

- Number of charges and discharges

- Possibility to charge gently to improve battery life

Infrastructure required

Small electronic devices (having secondary coils) are attached to the vehicles, which are capable of transferring high amounts of power. This power transfer is done wirelessly as the software used configures the right DC voltage directly to the battery pack.

Wireless charging is said to be less efficient but if power loss that occurs between the power grid and a wired charging point of the batteries is considered, the efficiency is a bit better. The communication link present between the coils can regulate the frequencies of the coils’ inductive field, and with this datalink interaction with the battery is easy.

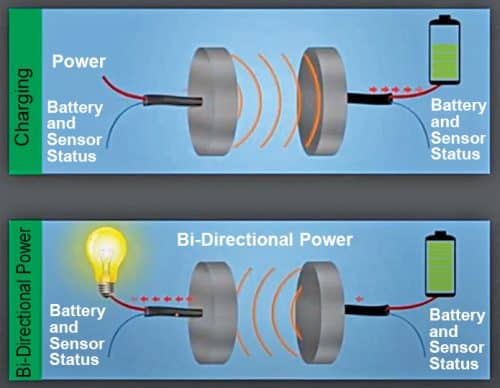

Therefore, with the communication link, it is easier to deliver the correct voltage and current. Misalignments or problems can also be dealt with by adjustment in frequency to maintain high efficiency. One of the unique features in wireless charging is that the energy can be pushed back to the grid, allowing a bidirectional flow of power over the same set of coils. With such benefits available, wireless charging is definitely better suited for charging batteries than a conductive solution.

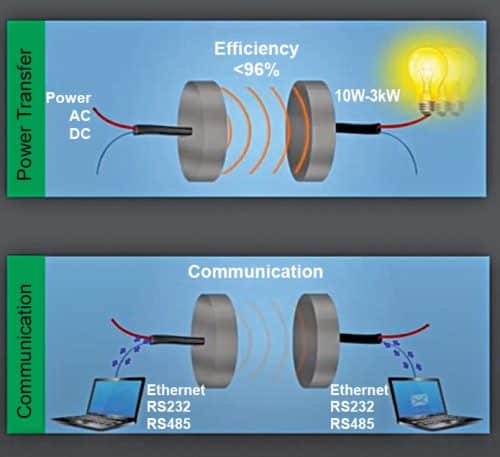

At the very core of the latest wireless technologies, a primary connector is made to send current to its coil to generate a magnetic field. This induces currents in the coil at the secondary connector. Both the coils are then precisely adjusted and trimmed for each product type and the magnetic fields are guided by a ferrite for maximum efficiency.

The strong magnetic field between both the connectors is used to transfer power. The primary and secondary connectors connect to each other using a very short range Wi-Fi that is designed to transfer data in the centre of this magnetic field. Ethernet user data is transmitted with low latency. The connectors also offer an RS232 or RS485 link using a separate antenna, and a dedicated internal communication link is present for power regulation and other system information.

The connectors can be controlled and be operated as a battery charger. Moreover, they have a two-way high-speed regulation channel that enables bidirectional power transfer. Hence, the same technology can be used to charge a battery as well as deliver energy from the battery as an inductive charger.

It would be interesting to know that 90% efficiency is achieved in most of the latest wireless power transfer systems, which is quite a fast rate of charging. The biggest advantage offered by the wireless systems is that they can control the batteries to prevent fire and can also report temperature fluctuations through the data link, so that the Li-ion cells can be disconnected if a risk of thermal runaway is found.

All these safety features, along with high efficiency, tick all boxes in terms of sustainability and proper use of energy. The automotive brands are now also focusing on developing compact and efficient secondary electronics for drones and other cost-sensitive products.

Infrastructure needed

For proper usage and charging of the vehicles an infrastructure that is maintained by a central server is needed. Micro-mobility startups and companies are developing solutions to manage shared mobility better.

Felyx, a Belgian micro-mobility startup, has developed a mobile app to locate, reserve, and connect with an e-scooter for urban transportation.

Duckt, another smart mobility startup, creates two-wheeler charging and parking stations that can be managed over an app.

Ground Control Systems, an American micro-mobility startup, provides ‘charge and park’ solutions over various campuses.

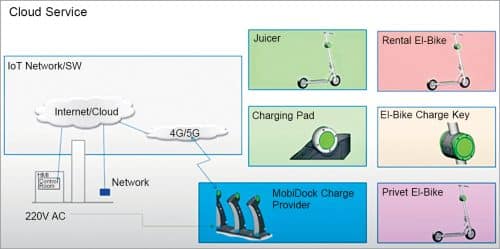

MobiDock, a Norwegian company, is putting 400 charging stations outside in a city of 15,000 people for electric two- and three-wheelers.

The infrastructure of shared micro-mobility provides a two-wheeler to go up to a nearby bus or metro station. The same micro-mobility can be used, after alighting from the bus or metro, to go to the final destination. As everything is connected to the cloud, the user can use the same ticket for the whole journey.

For seamless connectivity, every electric kick bike is equipped with an IoT charging device that automatically handshakes with the charging station and commences charging if they have an IoT match (that is both parties have an agreement to charge). The IoT charging device also equips a DC power charger, thus combining connectivity, data transfer, and charging in the same technology.

The technology for these applications has a data link that communicates with the cloud and allows a bike to be taken on rent. Once rented, the user is notified on the phone and everything from there is seamless. The user can view activities such as battery status, position of the bike, and available parking station. On a larger scale, shared mobility is more advantageous for private rental bike companies to enter the market without too much barrier in terms of infrastructure.

Similar to rental bikes, private bikes can also use the same infrastructure where the consumer is charged every time they stop. The usual startup cost and an hourly charge after being parked continues to remain the same. The ticket for a month for these bikes can be taken as a combination with other modes of transport such as metro and bus for a complete month.

Other micro-mobility applications

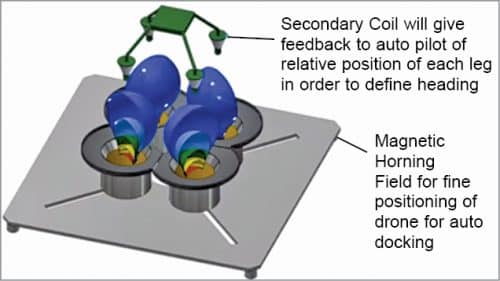

Micro-mobility can also be applied in aerial drones. The drones can be charged through their feet at their parking lot by inducing magnetic field. The secondary coil in a drone gives information about relative position of its each leg to the autopilot to define heading.

The primary coil in the parking station induces a magnetic field for fine positioning of the drone for automatic docking. The same technology can be used for charging boats on ports as well.

The autonomous robots can be used for agricultural applications too to enhance farm yields. Agriculture needs a lot of automation that can be handled through robots and tractors, and now in combination with aerial drones. This mobility enables moving things autonomously through a robust wireless, rather than moving people.

Micro-mobility in India

In a country like India, 2-wheelers are in big demand and micro-mobility is growing by a good margin as well. Statistics suggest 66% of the traffic in India is micro-mobile.

But the challenges that we face are currently global. The need for highly efficient and low-cost charging devices for electric vehicles is felt all over the world.

Helge Sverre Eide, Partner and Managing Director, Wireless Power and Communication (WPC Norway) says, “The government policy on electric vehicles is encouraging as it gives incentives to those who actually move into this EV business. Norway has utilised this procedure to promote EVs and ban the sale of combustion cars in the future. The government has taken a lot of effort for this, and I feel that India is doing the same.”

This article, based on a presentation by Helge Sverre Eide, Partner and Managing Director, Wireless Power and Communication (WPC Norway) at MOVES 2021, was prepared by Darshil Patel, a technology enthusiast with a deep interest in power electronics.