Larger wafers, lower cost

“As LED performance continues to improve, more and more lighting applications are becoming viable for LED lighting. Recent developments include the cost-effective replacement of linear and compact fluorescent light fixtures with LED lighting products, as well as the use of LED lighting products for commercial retail and display lighting,” says Thieken. “However, the challenges facing LEDs and LED lighting continue to be related to the higher first cost of LEDs versus traditional lighting and the need to simplify the use of LEDs when designing lighting products. Cree and other LED firms are constantly working to lower the cost of LEDs through the use of larger wafers, increased manufacturing efficiencies and greater performance. In addition, new advancements such as Cree’s recent ‘EasyWhite’ LEDs simplify the design and manufacturing of LED lighting products by eliminating the need for complex LED ‘mixing’ recipes when building these products.”

Like Cree, several other LED manufacturers (most of them being in Taiwan, Japan and China) have started using 10cm and even 15cm wafer substrates instead of the traditional 5cm ones. The larger the substrate, the lower the cost of production. As the industry moves to larger wafer sizes, LED manufacturers can reduce the cost and expand their manufacturing capacity even further.

[stextbox id=”info” caption=”Large-scale lighting, mega-scale benefits”]

Kapil Sood, director, Amptek, which claims to be India’s first LED customising company, explains that the use of LEDs for large-scale lighting solutions offers significant advantages in terms of the total cost of ownership.

“Performance of LED light fixtures can be divided into the light/optical efficacy, the electrical performance, and the outdoor protection from dust, water, etc. LED light fixtures are more efficient as no light is wasted and can be directed onto the surface or object. As for the electrical performance, we offer LED light fixtures using specially-designed constant-current drivers having a power factor greater than 0.97, efficiency greater than 85 per cent and total harmonic distortion less than 10 per cent. For protection of LED light fixtures, we offer International Protection Rating IP65/IP67/IP68 rated fixtures depending upon the usage, i.e., outdoor wall washers, fountain lights, swimming pool lights, etc,” he says.

He notices a lot of demand for customised lighting solutions in the commercial and industrial areas, as there is a great opportunity to replace halogen, T8 tubelights and compact fluorescent lamps with LED fixtures. LED lights have a life of over 50,000 hours. So, besides energy saving, the user also saves a lot on the cost of replacing the lamps frequently.

[/stextbox]

Researchers and manufacturers are also figuring out other techniques to lower the production cost of LEDs, and hence the price of LED-based products. One such method was announced by Cambridge University last year. It claims to have found a way of making gallium nitride (GaN)—a semiconductor used to make LEDs. This will enable production of LEDs at one-tenth of cur-rent costs, by using 15cm silicon wafers instead of 5cm sapphire wafers.

Helping burn the midnight oil

Apart from lowering the cost of production, the industry faces the challenge of increasing the performance of LEDs, that is, the amount of light produced per unit of electricity consumed (measured in lumens per watt (lm/W)). Today’s white LED fixtures average around 46 lm/W, which is much higher than what incandescent bulbs and fluorescent bulbs have been able to manage till date. Fixtures with 100 lm/W or even 140 lm/W are easily available off-the-shelf.

The greater the performance, the more the power saved, and the stronger the reason to buy LED-based products. No wonder, companies are constantly trying to increase the efficiency of their products.

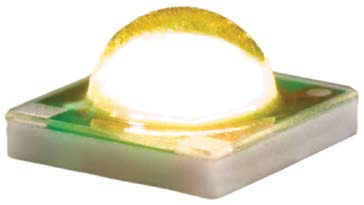

Just recently in February, Cree Inc. demonstrated a white LED with an efficacy of 208 lm/W. According to the press release, “Cree’s tests confirmed that the LED produced 208 lumens of light output and achieved 208 lumens per watt efficacy at a correlated colour temperature of 4579K. The tests were conducted under standard LED test conditions at a drive current of 350 mA at room temperature.” It might be a while before a 208lm/W product hits the market, but the company already offers lighting-class LEDs that can deliver upwards of 120 lumens per watt. “We have also recently introduced a multi-chip LED component optimised for use in LED directional bulbs that supplies 1500 lumens of light output,” notes Thieken.

He adds, “High-power LEDs will continue to offer increased levels of performance. We believe other developments will enable lighting customers to simplify their designs and manufacturing and also reduce the cost of LED lighting products.”