The simple and cost-effective ventilator project composing of 3D printed parts is a great contribution to reduce the ongoing ventilator shortage amidst the deadly coronavirus pandemic.

Thanks to engineers and electronics designers from all over the world, the medical staff involved in combating the deadly outbreak of COVID-19 are getting much-needed support. A team from MIT has already designed and launched a cost-effective ventilator in order to help hospitals cope with the shortage of ventilators as the number of infected cases continues to rise.

Like many, joining their efforts is a group of engineers and designers from Urbicum, a Polish 3D printing company, who have launched the VentilAid project. With a mission to enable better use of technology for fighting the coronavirus pandemic, the team has come up with an open-source ventilator design that is composed of very basic parts, which can be easily 3D printed.

Simple and effective design

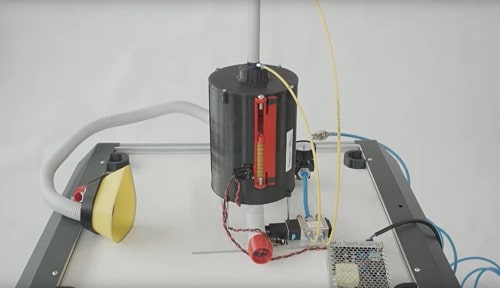

As of now, the team has come up with a working prototype for the ventilator that is composed of inexpensive 3D printed parts. These have been created using PLA/ABS/TPU/Flex materials. Utmost care has been taken to maintain proper regulation of air filtration, humidification, breathing rate and pressure.

Several industrial components such as pneumatic actuator (with 10 – 20cm stroke), pneumatic/electric limit switch with check valve and 12VDC power supply have also been included.

Szymon Chrupczalski, Manager at Urbicum and founder of the VentilAid concept said, “VentilAid’s main advantage over similar projects is that it does not require materials that are difficult to access. We’ve created a project of a fully functioning device at the total cost of about 50 euros for components.”

It is to be noted here that the team is awaiting the prototype’s final clinical testing. Therefore, it has strictly advised VentilAid to be used only as a last resort device when professional equipment is not available.

New prototype coming soon

The team is working on more ventilator projects which have low-cost 3D printed parts. This includes a second version of the VentilAid that uses a 12 V DC (car battery) / 120C AC – 230V AC (socket) and requires no compressed air nor a pneumatic actuator.

Visit general concepts and project documentation files for more information.